Foam nickel substrate Sn/SnO/SnO2 layered three-dimensional porous negative electrode material and preparation method thereof

A three-dimensional porous, negative electrode material technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor cycle performance, high cost of tin oxide negative electrode materials, complicated preparation process, etc., to achieve high porosity, suitable for The effect of industrial production and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

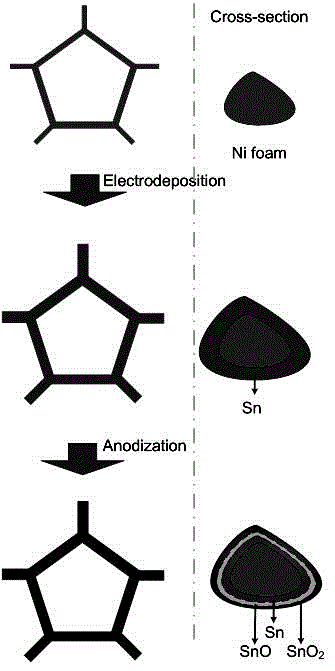

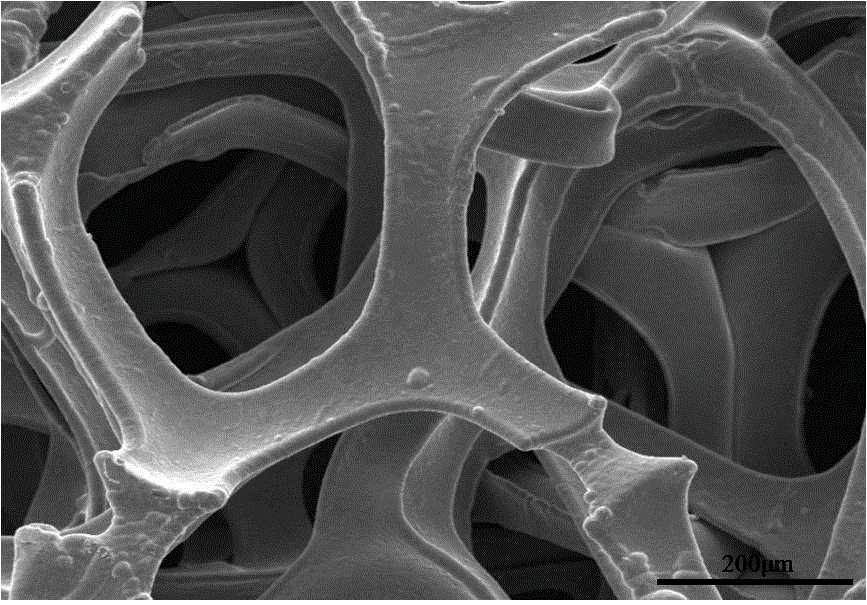

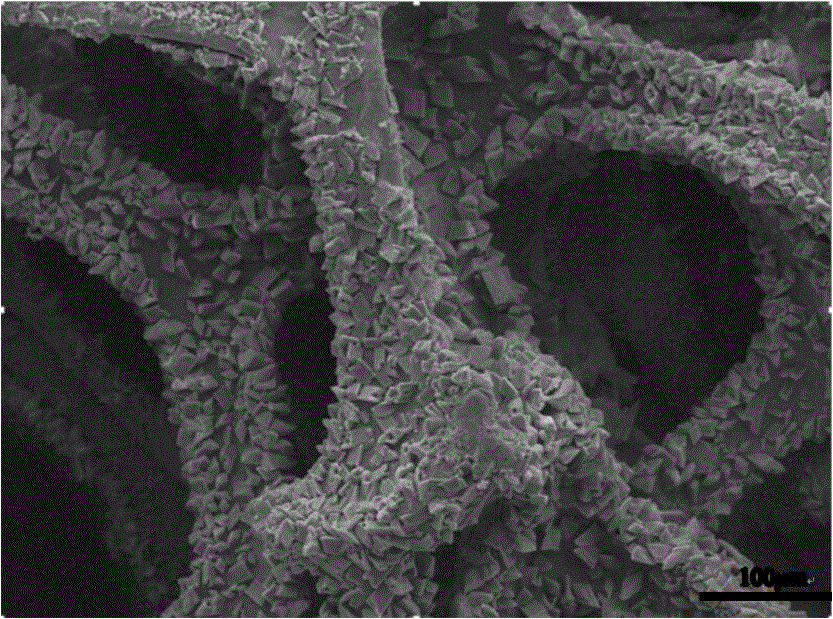

[0055] Nickel foam is selected as the electroplating substrate. figure 1 A schematic diagram of the design process for the entire experiment, figure 2 SEM image of nickel foam without any treatment.

[0056] (1) Pretreatment of nickel foam

[0057] For degreasing treatment, the solution configuration is as follows:

[0058]

[0059] Then carry out activation treatment, the solution configuration is as follows

[0060]

[0061] (2) Preparation of electroplating tin solution and anodizing solution

[0062] The formula and conditions for preparing the electroplating tin solution are as follows:

[0063]

[0064] (3) Put the nickel foam into the prepared tin plating solution, and the electroplating times are 300s, 500s, 700s, 900s, 1000s, and 1300s, respectively, to obtain electroplated tin samples.

[0065] (4) Put the sample obtained by electroplating in step (3) into an oxidizing solution, and perform anodizing treatment. The anodizing time is 200s, 300s, and 400...

Embodiment 2

[0075] In combination with Embodiment 1, a plating time of 300 s and an oxidation time of 200 s was selected as the experimental sample, and the remaining steps were the same as those of Embodiment 1. Using the conventional lithium-ion battery test method, the first charge-discharge specific capacity of the negative electrode effective material was 837mAh / g, and after 40 cycles, there was still 306mAh / g, and the average Coulomb efficiency reached 95%. The cycle performance is shown in the figure below. Image 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com