Control chip for LED (Light-Emitting Diode) driving

An LED driving and control chip technology, applied in the field of lighting, can solve the problems of increasing the energy consumption of the driving circuit, the large volume of the transformer, and the disadvantage of miniaturization, and achieve the effects of high stability, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

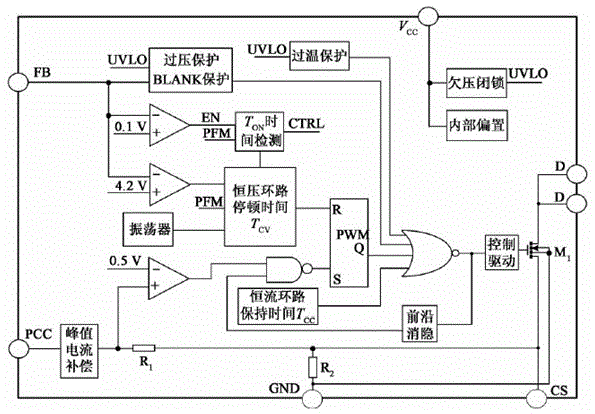

Method used

Image

Examples

Embodiment 1

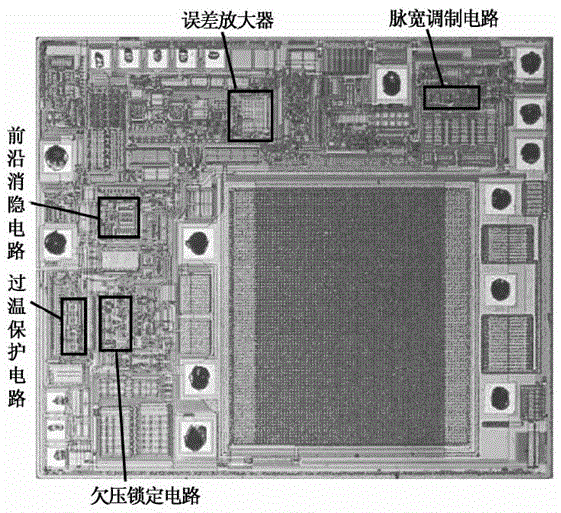

[0027] The chip layout of this implementation is as follows figure 2 As shown, the BCD1.5μm process is adopted, the chip size is 2.00mm×2.04mm, double-layer Al double-layer polycrystalline.

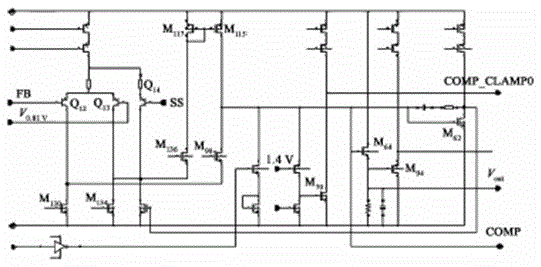

[0028] Wherein, the error amplification module circuit of the chip is as follows image 3 shown. The voltage at COMP is clamped high at 1.4V+Vgs. When the COMP voltage does not reach 1.4V+V gs When the COMP_CLAMP0 output is high level; when the COMP voltage reaches 1.4V+V gs , COM_CLAMP0 output is low level. The output of the error amplifier V out is clamped high at 1.4V. M64 and M62 have the same size, when the voltage at COMP has not risen to the NMOS tube voltage V th when M 64 with M 62are not turned on, V out The voltage is 0. m 62 The drain terminal voltage is high level, through the pull-down tube, the M 136 The source terminal voltage is pulled down to ground, then M 117 The current increases through the mirror, M 115 Charge the COMP, the COMP voltage is clamped lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com