Method of using carbon nanofiber layer to modify ultrafiltration membrane

A technology of carbon nanofiber and carbon fiber, which is applied in the field of environmental protection water treatment, can solve the problems of membrane pollution hindering the promotion and application of membrane technology, and achieve the effects of easy large-scale use and promotion, simple operation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

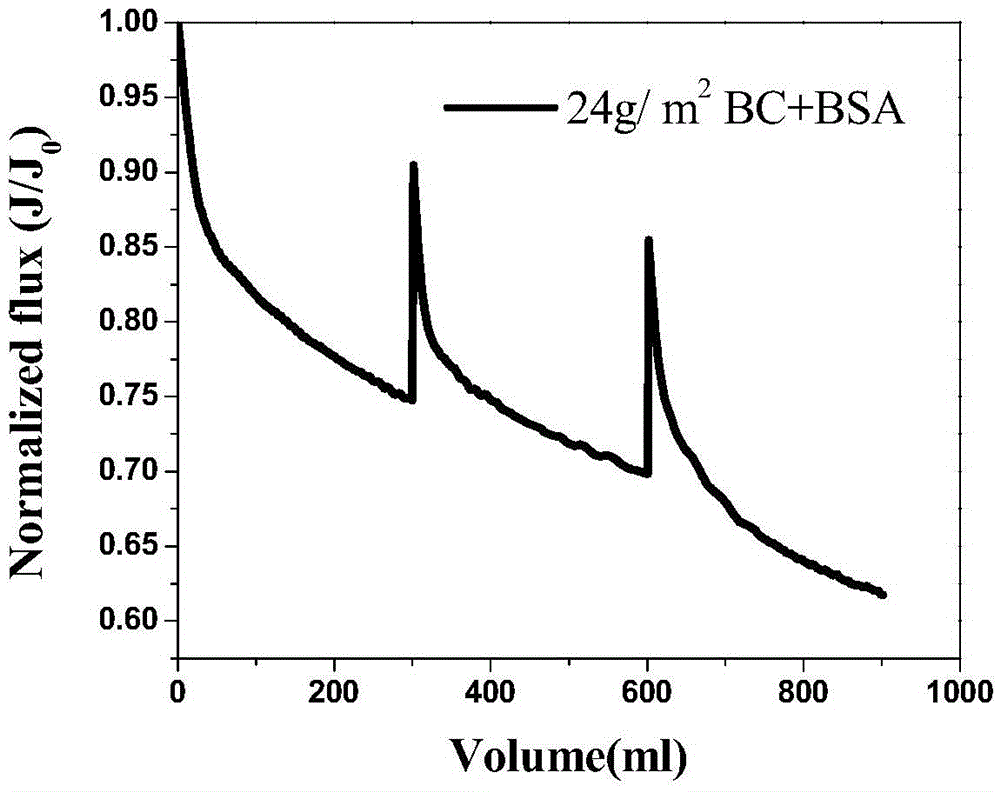

[0028] 1), cut the hydrogel-like bacterial cellulose into blocks (about 1*2*1.5cm 3 ), soaked in deionized water for two days, freeze-dried for 48 hours to form an airgel, and calcined at 950°C for 24 hours in an argon atmosphere, and then weighed the load to be 24g / m 2 The calcined bacterial cellulose was wetted with a small amount of deionized water dropwise, ground for 15 minutes, ultrasonically dispersed for 5 minutes, magnetically stirred in 50ml of deionized water for 10 minutes, and the uniformly dispersed bacterial cellulose was pre-deposited on a partial Polyvinyl fluoride ultrafiltration membrane surface.

[0029] 2), add 3 milliliters of 0.5M sodium bicarbonate solution in 300 milliliters of deionized water, then add 1 milliliter of 3g / L BSA stock solution, adjust the pH to 7±0.1 with 0.1M hydrochloric acid solution, the BSA solution 24g / m was pre-deposited in step 1) above 2 The polyvinylidene fluoride ultrafiltration membrane of bacterial cellulose is ultrafilte...

Embodiment example 2

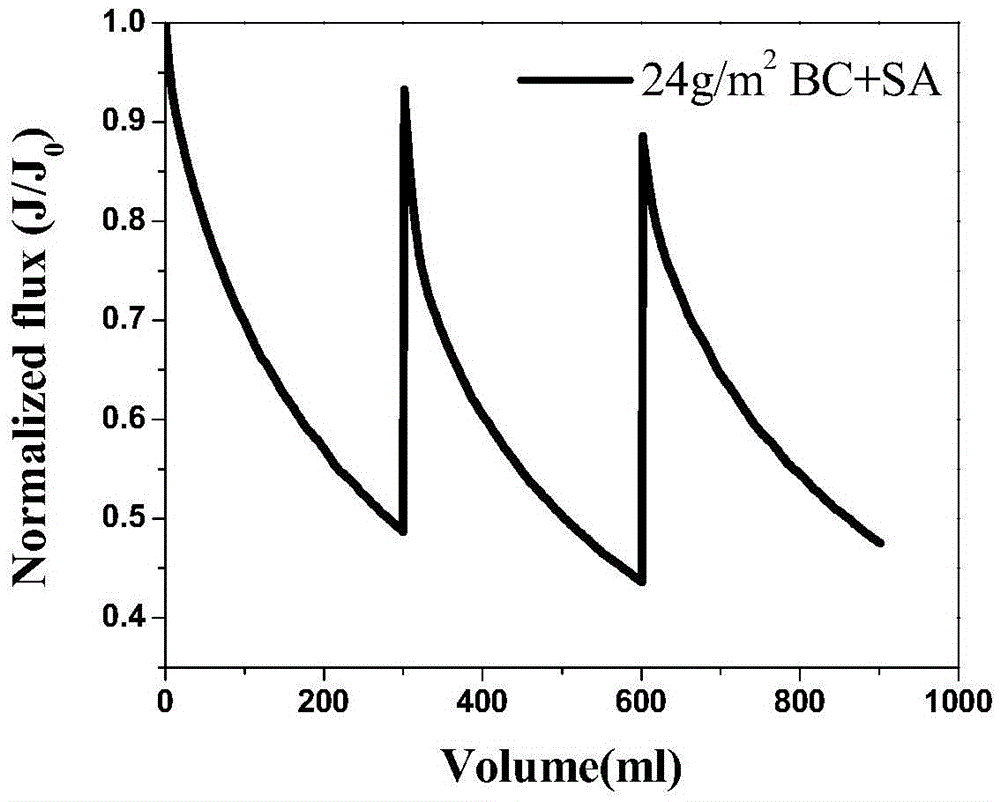

[0031] 1), cut the hydrogel-like bacterial cellulose into blocks (about 1*2*1.5cm 3 ), soaked in deionized water for two days, freeze-dried for 48 hours to form an airgel, and calcined at 950°C for 24 hours in an argon atmosphere, and then weighed the load to be 24g / m 2 The calcined bacterial cellulose was wetted with a small amount of deionized water dropwise, ground for 15 minutes, ultrasonically dispersed for 5 minutes, magnetically stirred in 50ml of deionized water for 10 minutes, and the uniformly dispersed bacterial cellulose was pre-deposited on a partial Polyvinyl fluoride ultrafiltration membrane surface.

[0032] 2), add 3 milliliters of 0.5M sodium bicarbonate solution to 300 milliliters of deionized water, then add 1 milliliter of 3g / L SA stock solution, adjust the pH to 7±0.1 with 0.1M hydrochloric acid solution, and use the SA solution with 24g / m was pre-deposited in the above step 1) 2 The polyvinylidene fluoride ultrafiltration membrane of bacterial cellulos...

Embodiment example 3

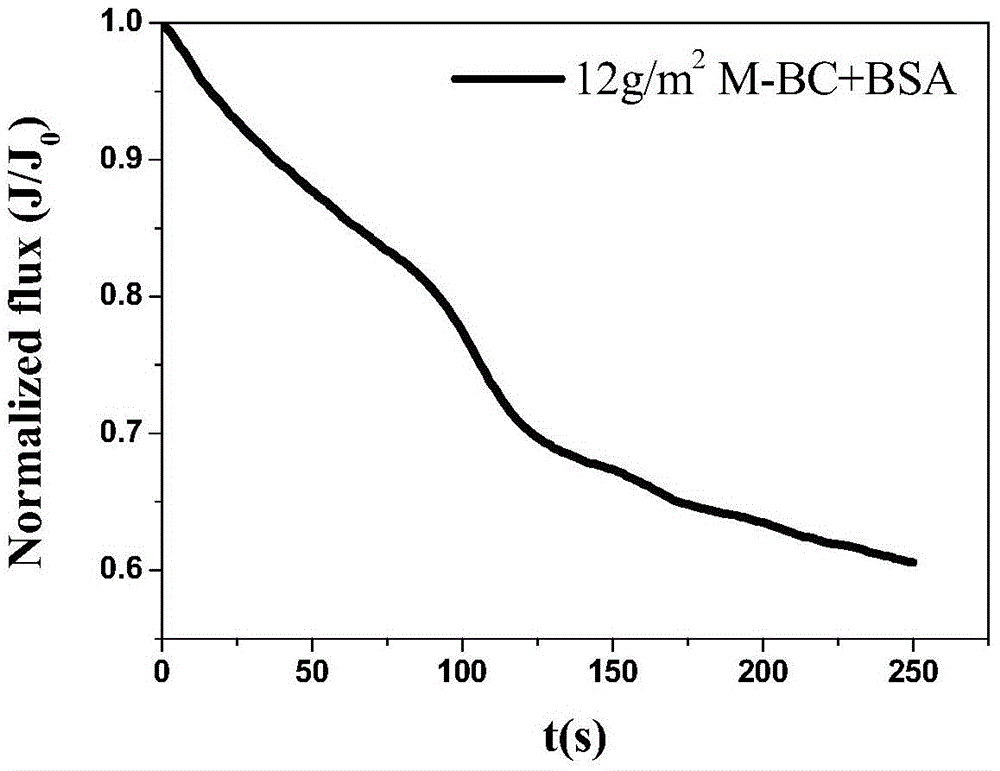

[0034] 1), cut the hydrogel-like bacterial cellulose into blocks (about 1*2*1.5cm 3 ), soaked in deionized water for two days, freeze-dried for 48 hours to form an airgel, and calcined at 950°C for 24 hours in an argon atmosphere, and then weighed the load to be 12g / m 2 The calcined bacterial cellulose was wetted with a small amount of ethanol, ground for 15 minutes, ultrasonically dispersed for 5 minutes, then magnetically stirred in a mixture of 35ml ethanol and 15ml N-methylpyrrolidone for 24 hours, and uniformly dispersed by Bacterial cellulose modified with ethanol and N-methylpyrrolidone was pre-deposited on the surface of polyvinylidene fluoride ultrafiltration membrane.

[0035] 2), add 3 milliliters of 0.5M sodium bicarbonate solution in 300 milliliters of deionized water, then add 1 milliliter of 3g / L BSA stock solution, adjust the pH to 7±0.1 with 0.1M hydrochloric acid solution, use the BSA solution 12g / m was pre-deposited in the above step 1) 2 The polyvinyliden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com