Preparation method of Pd/ZIF-67/TiO2 nanotube composite catalyst

A composite technology of ZIF-67 and nanotubes, which is applied in the field of material chemistry, can solve the problems of low utilization efficiency of visible light and large specific surface area of nanotubes, and achieve the effects of high recyclability, large specific surface area and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

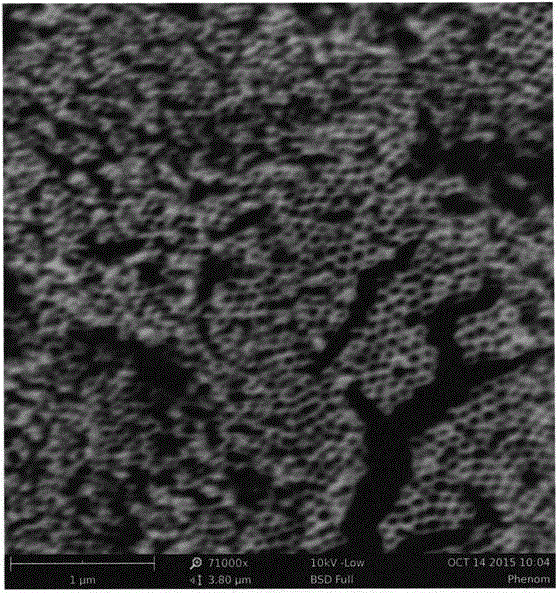

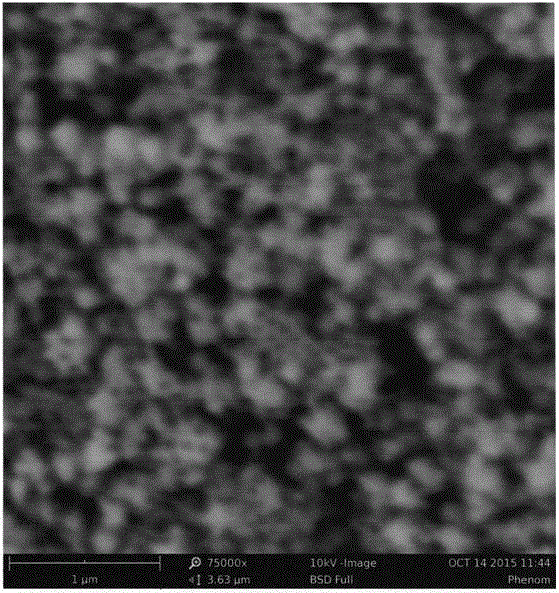

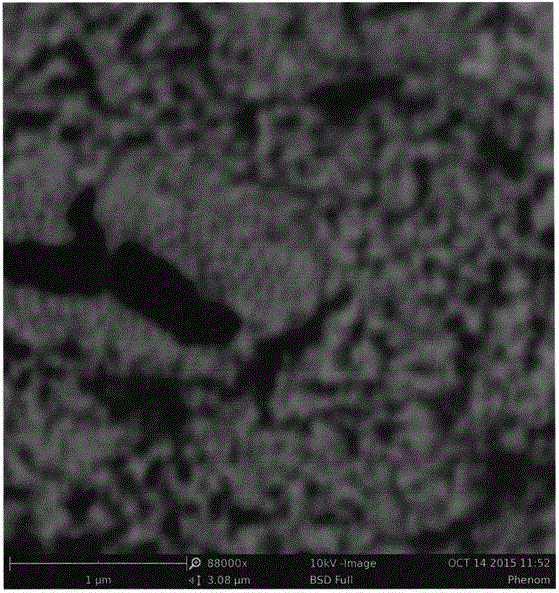

Image

Examples

Embodiment 1

[0030] (1) Configure 1mol / L HF and 1mol / L HNO 3 The mixed solution was used as an etchant for a 0.8 mm titanium plate, etched for 50 s, and the etched titanium plate was cleaned with deionized water.

[0031] (2) Configure NH 4 F (0.3wt%) and H 2 The ethylene glycol solution of O (1wt%) is used as the electrolyte, the pure carbon plate is used as the cathode, the titanium plate obtained in step (1) is used as the anode, and the two poles are kept at a distance of 1.5 cm, and the reaction is carried out at a constant voltage of 30V for 5h to obtain TiO 2 nanotube matrix.

[0032] (3) TiO obtained in step (2) 2 Nanotubes were annealed at 500 °C.

[0033] (4)0.57gCo(NO 3 )·6H 2 O was dissolved in 40ml of methanol solution and 0.32g of 2-methylimidazole was dissolved in 40ml of methanol solution, the two solutions were mixed, and the TiO2 nanomatrix was immersed in it to obtain ZIF-67 / TiO 2 nanotube matrix.

[0034] (5) Immerse the substrate obtained in step (4) into 0.1mo...

Embodiment 2

[0036] (1) Configure 1mol / L HF and 1.5mol / L HNO 3 The mixed solution was used as an etchant for a 0.8 mm titanium plate, etched for 40 s, and the etched titanium plate was cleaned with deionized water.

[0037] (2) Configure NH 4 F (0.35wt%) and H 2 The ethylene glycol solution of O (2wt%) is used as the electrolyte, the pure carbon plate is used as the cathode, the titanium plate obtained in step (1) is used as the anode, and the two poles are kept at a distance of 1.5 cm, and the reaction is carried out at a constant voltage of 30V for 8h to obtain TiO 2 nanotube matrix.

[0038] (3) TiO obtained in step (2) 2 The nanotubes were annealed at 550 °C.

[0039] (4)0.29gCo(NO 3 )·6H 2 O was dissolved in 20ml of methanol solution and 0.24g of 2-methylimidazole was dissolved in 20ml of methanol solution, the two solutions were mixed, and the TiO 2 ZIF-67 / TiO obtained by dipping the nano-matrix into it 2 nanotube matrix.

[0040] (5) Immerse the substrate obtained in step (...

Embodiment 3

[0042] (1) Configure 3mol / L HF and 5mol / L HNO 3 The mixed solution was used as an etchant for a 1.0 mm titanium plate, etched for 30 s, and the etched titanium plate was cleaned with deionized water.

[0043] (2) Configure NH 4 F (0.4wt%) and H 2 The ethylene glycol solution of O (2.5wt%) is used as the electrolyte, the pure carbon plate is used as the cathode, the titanium plate obtained in step (1) is used as the anode, and the two poles are kept at a distance of 2 cm, and the reaction is carried out at a constant voltage of 40V for 10h to obtain TiO 2 nanotube matrix.

[0044] (3) TiO obtained in step (2) 2 The nanotubes were annealed at 550 °C.

[0045] (4) 1.15gCo(NO 3 )·6H 2 O was dissolved in 40ml of methanol solution and 1.29g of 2-methylimidazole was dissolved in 40ml of methanol solution, the two solutions were mixed, and the TiO 2 ZIF-67 / TiO obtained by dipping the nano-matrix into it 2 nanotube matrix.

[0046] (5) Immerse the substrate obtained in step (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com