High-carbon spent catalyst continuous regeneration method

A catalyst to be produced, catalyst technology, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc. Excessive pressure drop and other problems, to achieve the effect of preventing flying temperature, reducing frequency and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

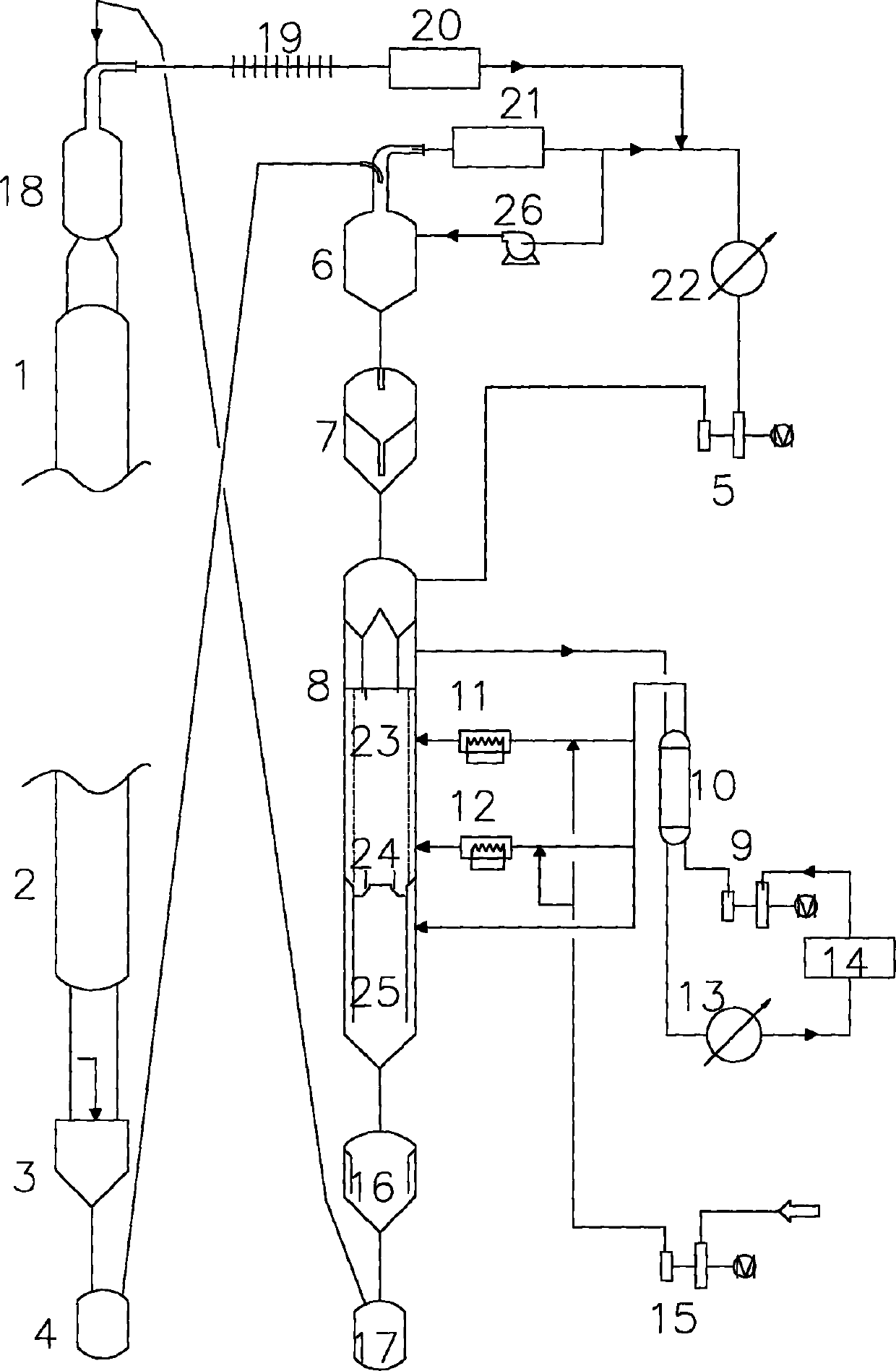

[0031] The unborn catalyst from the reaction part enters the reactor lower hopper 3 at the bottom of the last reactor 2, and first replaces the carried hydrocarbons with nitrogen, and then enters the reactor riser 4, which uses self-circulating nitrogen The nitrogen from the compressor 5 lifts the raw catalyst to the separation hopper 6 at the top of the regenerator 8, where the raw catalyst enters the lock hopper 7 in a nitrogen environment after the dust is blown off by the elutriation gas, and then enters the regenerator 8. The control system of the lock hopper 7 controls the five steps of waiting, pressurization, discharge, depressurization and charging of the lock hopper 7 through pressure balance, and sends the catalyst from the separation hopper 6 to the regenerator 8 and controls the catalyst flow rate. The coke regeneration process is completed in the regenerator 8, and the regenerated catalyst enters the regenerator lower hopper 16 and is replaced with nitrogen, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com