Preparation process of wide-temperature low-power-consumption manganese zinc ferrite powder

A technology for power consumption of manganese-zinc and ferrite powder, applied in the fields of iron compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problem of limited application range, inability to guarantee saturation magnetic flux density, and inability to guarantee stable Curie temperature magnetic properties problems such as low power loss, high saturation magnetic flux density, high Curie temperature and resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation process of manganese zinc ferrite powder with wide temperature and low power consumption, comprising the following steps:

[0028] (1) Mixing of ingredients:

[0029] Take the following components in parts by weight: 68.91-70.31 parts of ferric oxide, 21.89-24.86 parts of trimanganese tetroxide, 6.21-9.2 parts of zinc oxide, add to the conical mixer and mix evenly, and send the mixed raw materials into Vibrating mill to make mixed powder;

[0030] (2) Rolled sheet:

[0031] The mixed powder is sent to the silo of the granulator, and the rolling pressure is 9-11MPa, and the mixed powder is rolled into flakes;

[0032] (3) Pre-burning:

[0033] The flakes are sent to the rotary kiln for pre-burning through the feeder, and the temperature of the rotary kiln is raised to 800-850°C, and then sintered at a constant temperature;

[0034] (4) Coarse vibration:

[0035] Under the condition of water cooling, the pre-burned pellets are sent to the vibration mill...

Embodiment 2

[0054] Embodiment two, embodiment three, embodiment four, embodiment five, embodiment six:

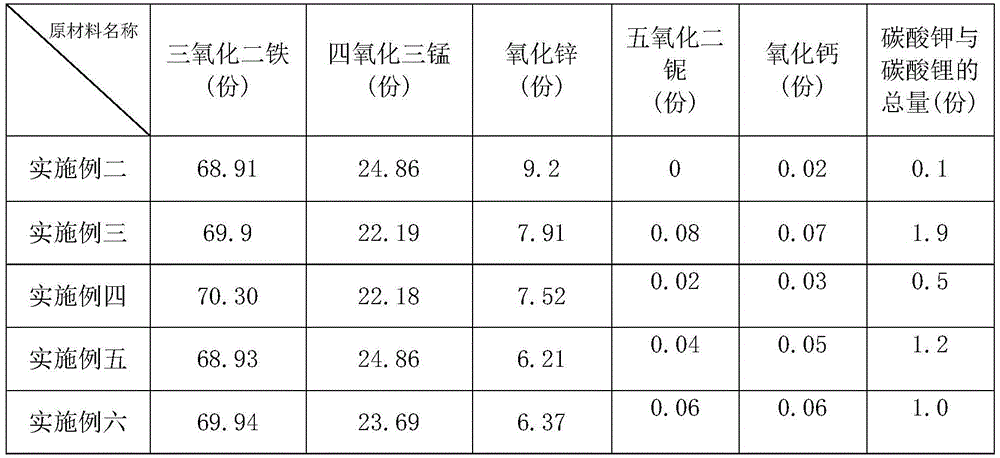

[0055] A kind of manganese-zinc ferrite powder with wide temperature and low power consumption, the specific composition of formula by weight parts corresponds to Table 1:

[0056] Table 1: Formula composition of manganese zinc ferrite powder with wide temperature and low power consumption in parts by weight

[0057]

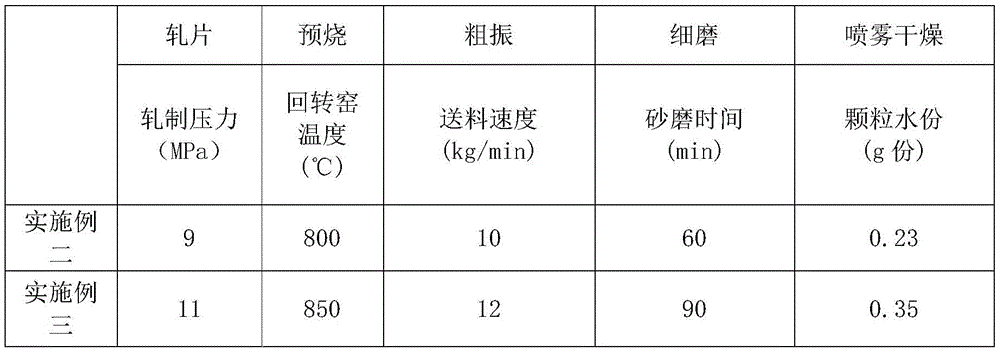

[0058] The production process is basically the same as in Example 1, and the specific process conditions correspond to Table 2 one by one:

[0059] Table 2: Preparation process of manganese zinc ferrite powder with wide temperature and low power consumption

[0060]

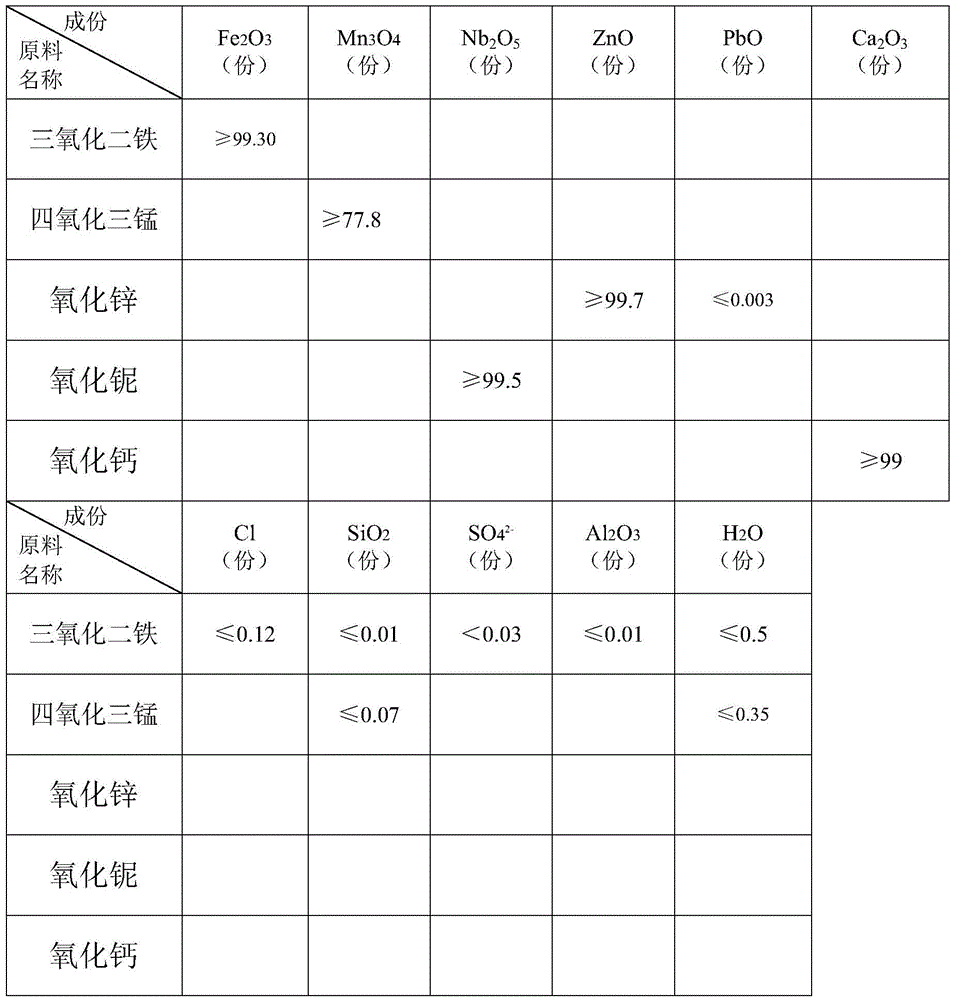

[0061] The wide temperature and low power consumption manganese zinc ferrite powder in embodiment 1 to embodiment 6, the quality and standard correspondence table 3 of main raw material by weight part:

[0062] Table 3: Quality and standards of main raw materials by weight

[0063]

[0064] The ...

Embodiment 6

[0068] The sample of embodiment six, its initial magnetic permeability μ i It is 3200±25%, the saturation magnetic flux density Bs is 520mT at H=1194A / m, 25°C, the saturation magnetic flux density Bs is 410mT at H=1194A / m, 100°C, and the Curie temperature is not lower than 220°C , power loss PL is 400kW / m at 100kHz, 200mT, 25℃ 3 , power loss PL is 340kW / m at 100kHz, 200mT, 100℃ 3 , the resistivity is greater than 7.0Ω·m. It exhibits excellent and stable magnetic properties in a wide temperature range from 25°C to 100°C, and has the characteristics of high saturation magnetic flux density and low power loss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com