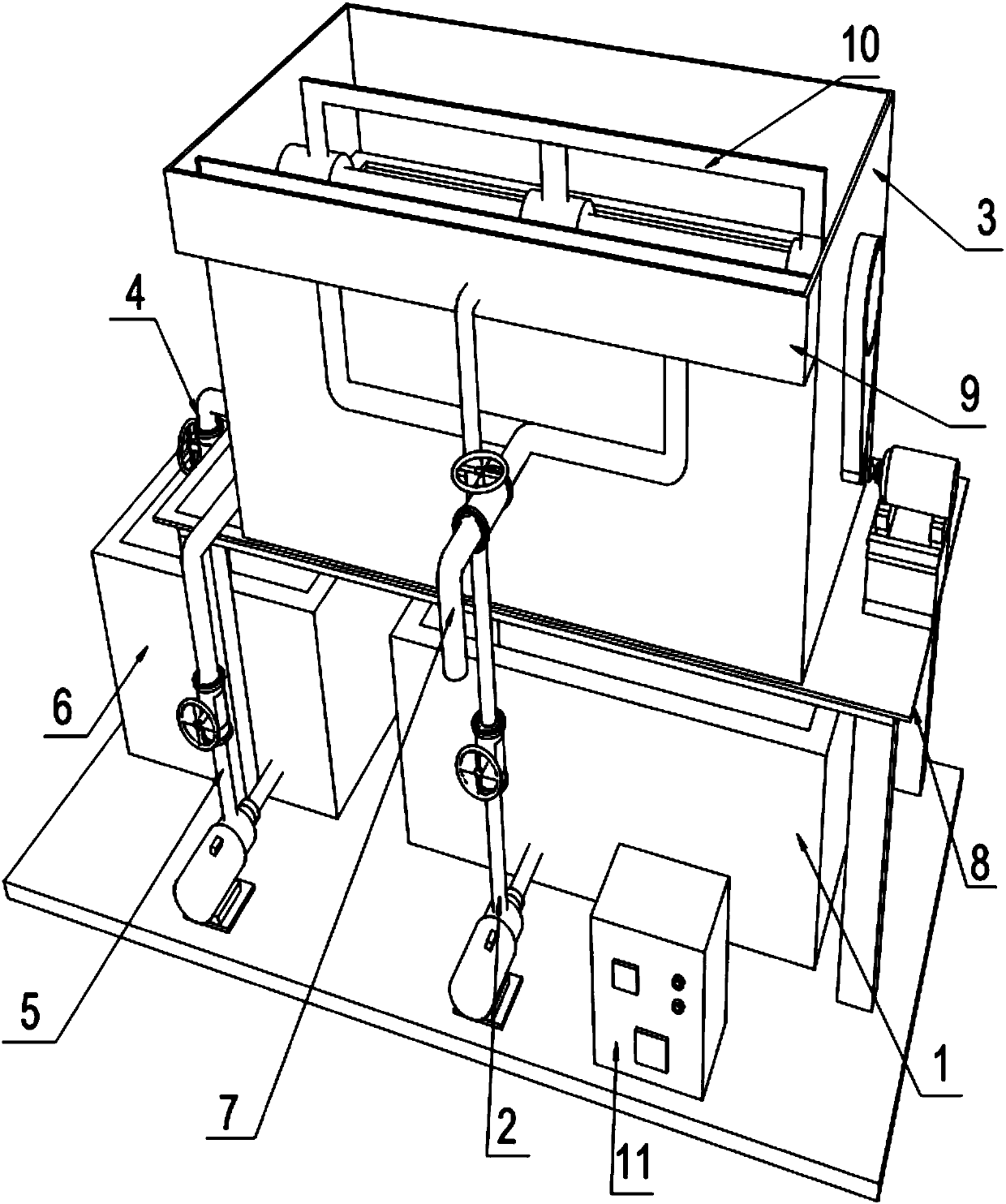

A vertical fast water purification device and water purification method thereof

A technology of water purification device and water inlet device, which is applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of unadjustable process parameters, substandard effluent water quality, and short design of filter tanks. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

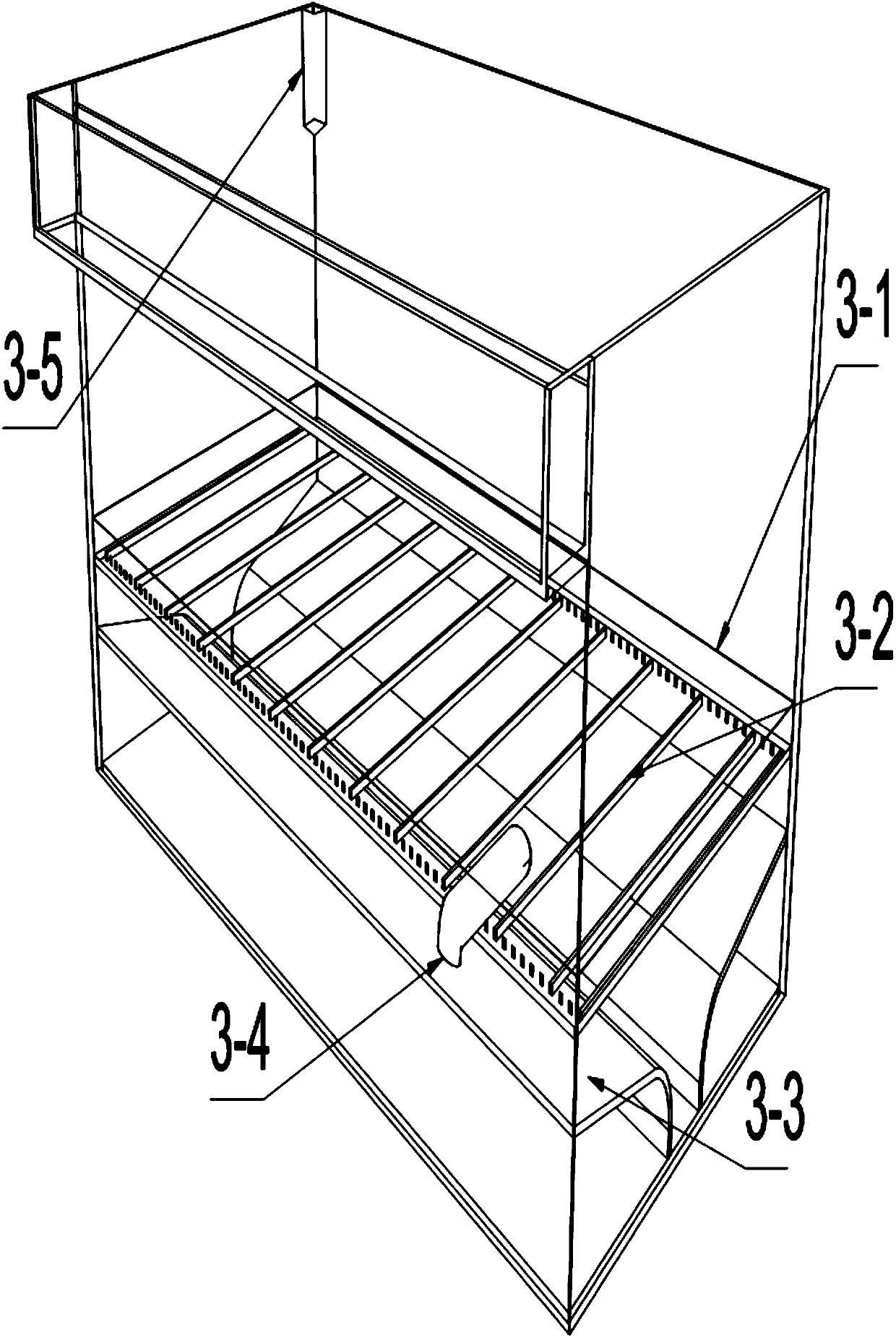

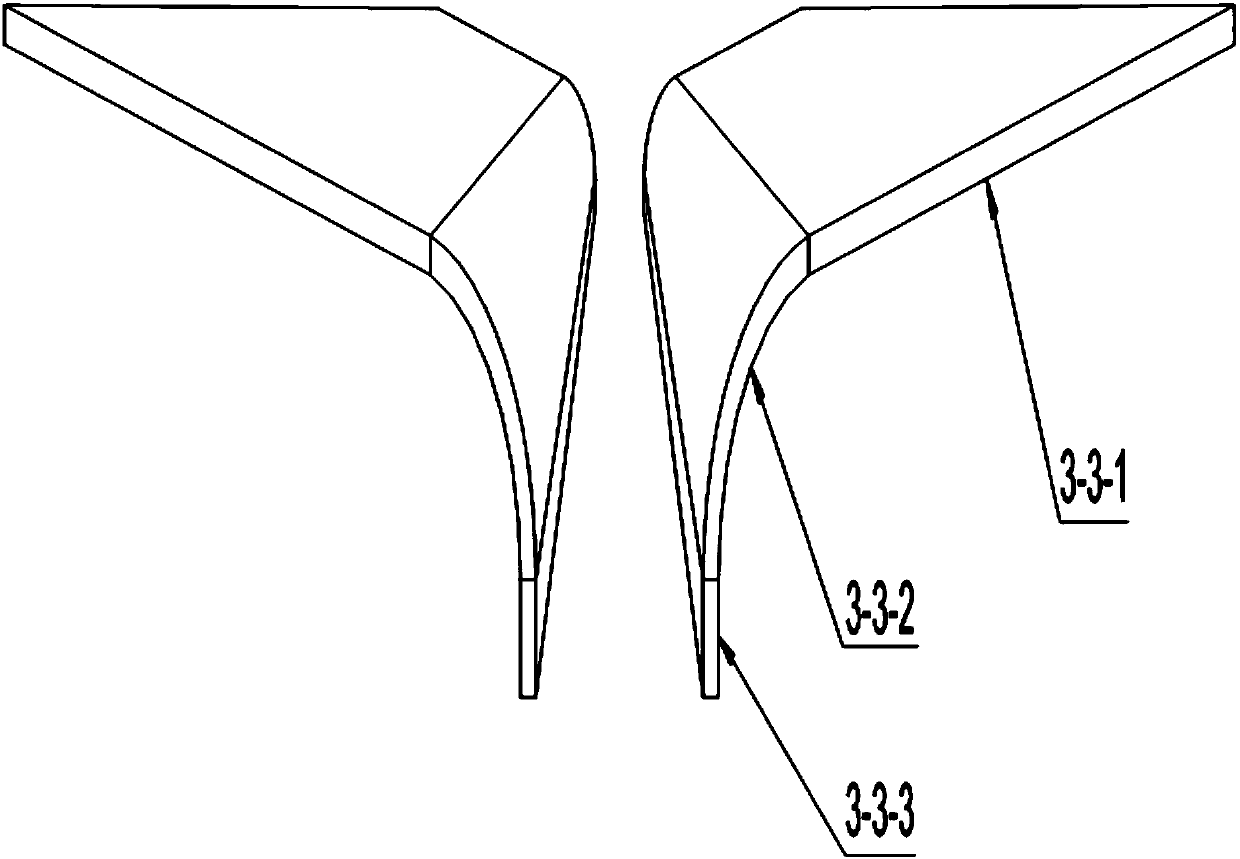

Method used

Image

Examples

Embodiment 1

[0058] 1. According to the following steps, manufacture the long plate 10-3-1 of the present invention in parts by weight:

[0059]Step 1: Add 300 parts of ultrapure water with a conductivity of 0.0005μS / cm into the reactor, start the stirrer in the reactor at a speed of 120rpm, start the heating pump, and increase the temperature in the reactor to 30°C; add in sequence 2 parts of hexyl n-octyl ether, 1 part of N,N-dimethylglycinate, 1 part of ethylsulfonyl chloride, stir until completely dissolved, adjust the pH value to 4.0, adjust the stirrer speed to 70rpm, and the temperature to 60 ℃, esterification reaction for 2 hours;

[0060] Step 2: Take 8 parts of 3,3',4,4'-tetramethyldiphenylethane and 4 parts of pyromellitic phthalic anhydride to pulverize, the particle size of the powder is 500 mesh; add 2,2-dimethyl - Mix 15 parts of propionic anhydride evenly, spread it on the tray with a thickness of 30 mm, and irradiate it with gamma rays with a dose of 2.5 kGy and an energy...

Embodiment 2

[0071] 1. According to the following steps, manufacture the long plate 10-3-1 of the present invention in parts by weight:

[0072] Step 1: Add 1,000 parts of ultrapure water with a conductivity of 0.02μS / cm into the reactor, start the stirrer in the reactor at a speed of 191rpm, start the heating pump, and raise the temperature in the reactor to 70°C; add in order 25 parts of hexyl n-octyl ether, 30 parts of N,N-dimethylglycinate, 18 parts of ethylsulfonyl chloride, stir until completely dissolved, adjust the pH value to 9.0, adjust the speed of the stirrer to 95rpm, and the temperature to 80 ℃, esterification reaction for 11 hours;

[0073] Step 2: Take 20 parts of 3,3',4,4'-tetramethyldiphenylethane and 18 parts of pyromellitic phthalic anhydride to pulverize, the particle size of the powder is 600 mesh; add 2,2-dimethyl - Mix 25 parts of propionic anhydride evenly, spread it on the tray with a thickness of 40 mm, and irradiate it with gamma rays with a dose of 5.5 kGy and...

Embodiment 3

[0084] 1. According to the following steps, manufacture the long plate 10-3-1 of the present invention in parts by weight:

[0085] Step 1: Add 378 parts of ultrapure water with a conductivity of 0.000785μS / cm into the reactor, start the stirrer in the reactor at a speed of 145rpm, and start the heating pump to raise the temperature in the reactor to 37°C; add in order 12 parts of hexyl n-octyl ether, 12 parts of N,N-dimethylglycinate, 12 parts of ethylsulfonyl chloride, stir until completely dissolved, adjust the pH value to 5.0, adjust the speed of the agitator to 78rpm, and the temperature to 78 ℃, esterification reaction for 10 hours;

[0086] Step 2: Take 10 parts of 3,3',4,4'-tetramethyldiphenylethane and 10 parts of pyromellitic phthalic anhydride to pulverize, the particle size of the powder is 550 mesh; add 2,2-dimethyl - Mix 20 parts of propionic anhydride evenly, spread it on the tray with a thickness of 35 mm, and irradiate it with gamma rays with a dose of 2.9 kG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com