Dimethylamine waste water treatment method capable of recovering dimethyl formamide (DMF)

A technology for wastewater treatment and dimethylamine, which is applied in multi-stage water treatment, water/sewage treatment, heating water/sewage treatment, etc. It can solve the problems of waste of resources, cumbersome operation of high-concentration wastewater regeneration, and high cost, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

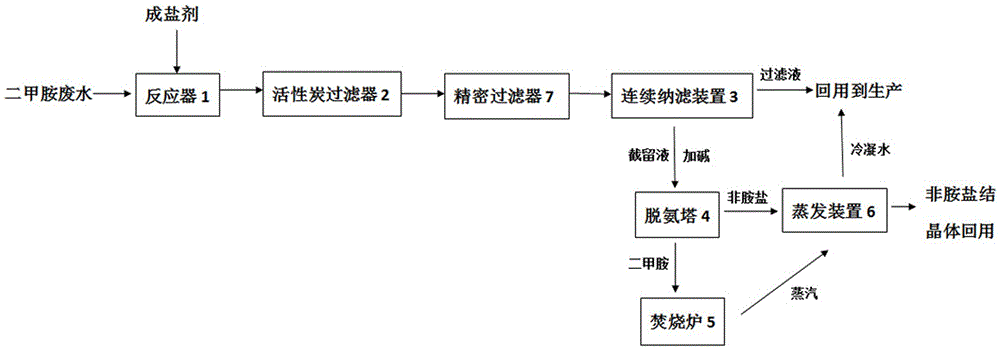

[0037] A kind of dimethylamine wastewater treatment method that reclaims DMF comprises the following steps:

[0038] a. Pass the dimethylamine waste water into the mechanically stirred reactor 1, add the salt-forming agent sulfuric acid, stir and mix, the pH value is 6.5, and carry out the salt-forming reaction;

[0039] b. The waste liquid after the salt-forming reaction is passed into the continuous nanofiltration device 3, and the filtrate through the continuous nanofiltration device 3 is recycled to production;

[0040] c. Add sodium hydroxide to the retained liquid that has not passed through the continuous nanofiltration device 3, adjust the pH value to 11, the retained liquid enters the deamination tower 4 for stripping, and the dimethylamine gas is discharged from the top of the deamination tower 4 , the bottom of the deamination tower 4 is a non-amine salt concentrate;

[0041] d. The dimethylamine gas discharged from the top of the tower enters the incinerator 5 for...

Embodiment 2

[0045] A kind of dimethylamine wastewater treatment method that reclaims DMF comprises the following steps:

[0046] a. Pass the dimethylamine waste water into the mechanically stirred reactor 1, add the salt-forming agent sulfuric acid, stir and mix, the pH value is 3, and carry out the salt-forming reaction;

[0047] b. Pass the waste liquid after the salt-forming reaction into the activated carbon filter 2 at a flow rate of 30m / h to remove oil and other organic impurities in the waste liquid;

[0048] c. The waste liquid treated by the activated carbon adsorber 2 is filtered through a precision filter 7 with a filtration accuracy of 5um, and the filtrate enters the continuous nanofiltration device 3, and the filtrate passed through the continuous nanofiltration device 3 is reused for production;

[0049] d. Add sodium hydroxide to the retentate that does not pass through the continuous nanofiltration device 3, adjust the pH value to 11, and the retentate deammonization tower ...

Embodiment 3

[0054] A kind of dimethylamine wastewater treatment method that reclaims DMF comprises the following steps:

[0055] a. Pass dimethylamine waste water into the mechanically stirred reactor 1, add the salt-forming agent sulfuric acid, stir and mix, the pH value is 5, and carry out the salt-forming reaction;

[0056] b. Pass the waste liquid after the salt-forming reaction into the active carbon filter 2 at a flow rate of 3m / h to remove oil and other organic impurities in the waste liquid;

[0057] c. The waste liquid treated by the activated carbon adsorber 2 is filtered through a precision filter 7 with a filtration accuracy of 10um, and the filtrate enters the continuous nanofiltration device 3, and the filtrate passed through the continuous nanofiltration device 3 is reused for production;

[0058] d. Add sodium hydroxide to the retentate that does not pass through the continuous nanofiltration device 3, adjust the pH value to 11, and the retentate deammonization tower 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com