Method for producing furfural by aid of pre-hydrolysis liquid of eucalyptus

A technology of pre-hydrolyzed solution and eucalyptus, which is applied in the direction of organic chemistry, can solve the problems of waste of biomass resources, increase the amount of alkali used for cooking, etc., and achieve the effect of improving utilization rate, increasing furfural yield, and reducing coking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

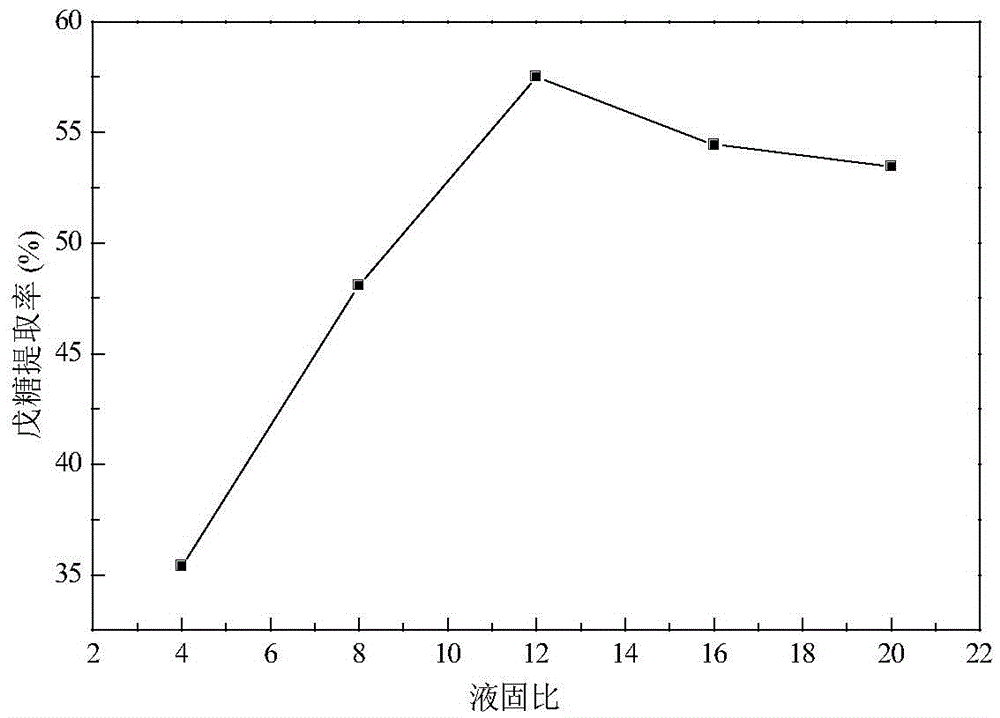

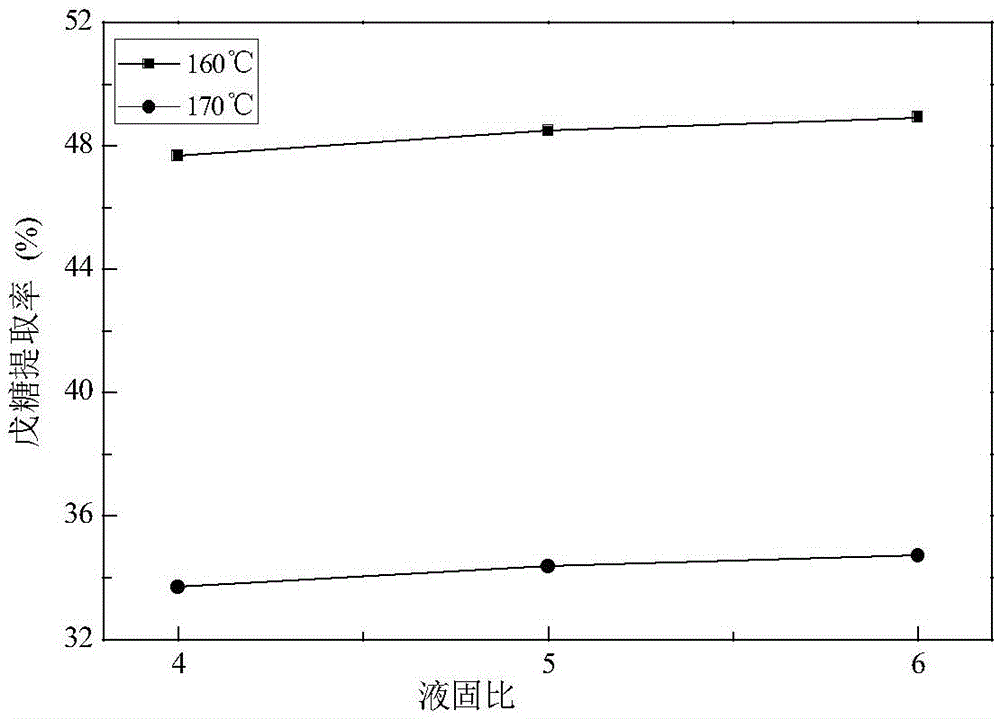

[0050] Example 1 Effect of eucalyptus prehydrolysis conditions on hemicellulose extraction.

[0051] Method 1: Wash the eucalyptus chips in water at 60°C and steam them for 30 minutes, use a double-screw extruder to crush and tear the eucalyptus chips, grind them and place them in a digester (US M / K609-2- 10 type digester), add water, the liquid-solid ratio is 12:1, heat up to 170°C, the heating rate is 2°C / min, and then keep warm for pre-hydrolysis, wherein the hold time is 60min, to obtain eucalyptus pre-hydrolysis Hydrolyzate.

[0052] Method 2: The eucalyptus wood pre-hydrolyzate is prepared by the steps similar to the above method 1, the difference is that the eucalyptus wood chips are steamed, double-screw extruded and ground without being washed in water.

[0053] The liquid-solid ratio, hydrolysis reaction time and reaction temperature of the two methods were changed respectively to investigate the effect of each influencing factor on the extraction effect of hemicell...

Embodiment 2

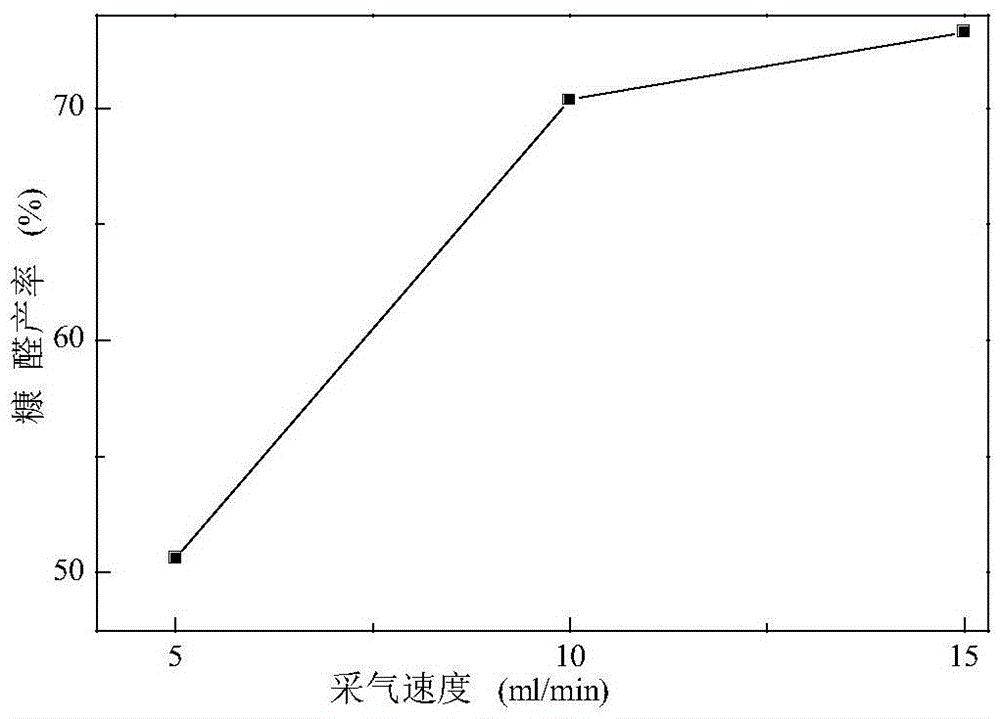

[0063] The preparation of embodiment 2 furfural.

[0064] The variety of eucalyptus wood chips is an improved variety of Congo No. 12 eucalyptus, which is obtained from a pulp company in Guangxi. Using method 1 in Example 1, eucalyptus wood chips were prepared under the conditions of a temperature of 170 ° C, a holding time of 60 min, and a liquid-solid ratio of 5:1. The hydrolyzed waste liquid was stored in cold storage for later use. The pH value of the waste liquid was 3.11, and the contents of solids, xylose and xylo-oligosaccharides were 40.45g / L, 14.11g / L and 3.43g / L respectively.

[0065] The experimental steps are:

[0066] (1) Check the airtightness of the autoclave before the test, and use it after confirming that there is no leakage;

[0067] (2) Eucalyptus prehydrolyzate and sulfuric acid catalyst are added in the reaction kettle, the lid of the kettle is tightened, the power is turned on, the condensed water is turned on, and the temperature starts to rise after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com