Environment-friendly bicomponent waterborne polyurethane camouflage paint preparation method

A water-based polyurethane and two-component technology, applied in polyurea/polyurethane coatings, camouflage coatings, coatings, etc., can solve problems that endanger the health of construction workers and environmental pollution, and achieve construction safety, environmental friendliness, and low VOC emissions volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

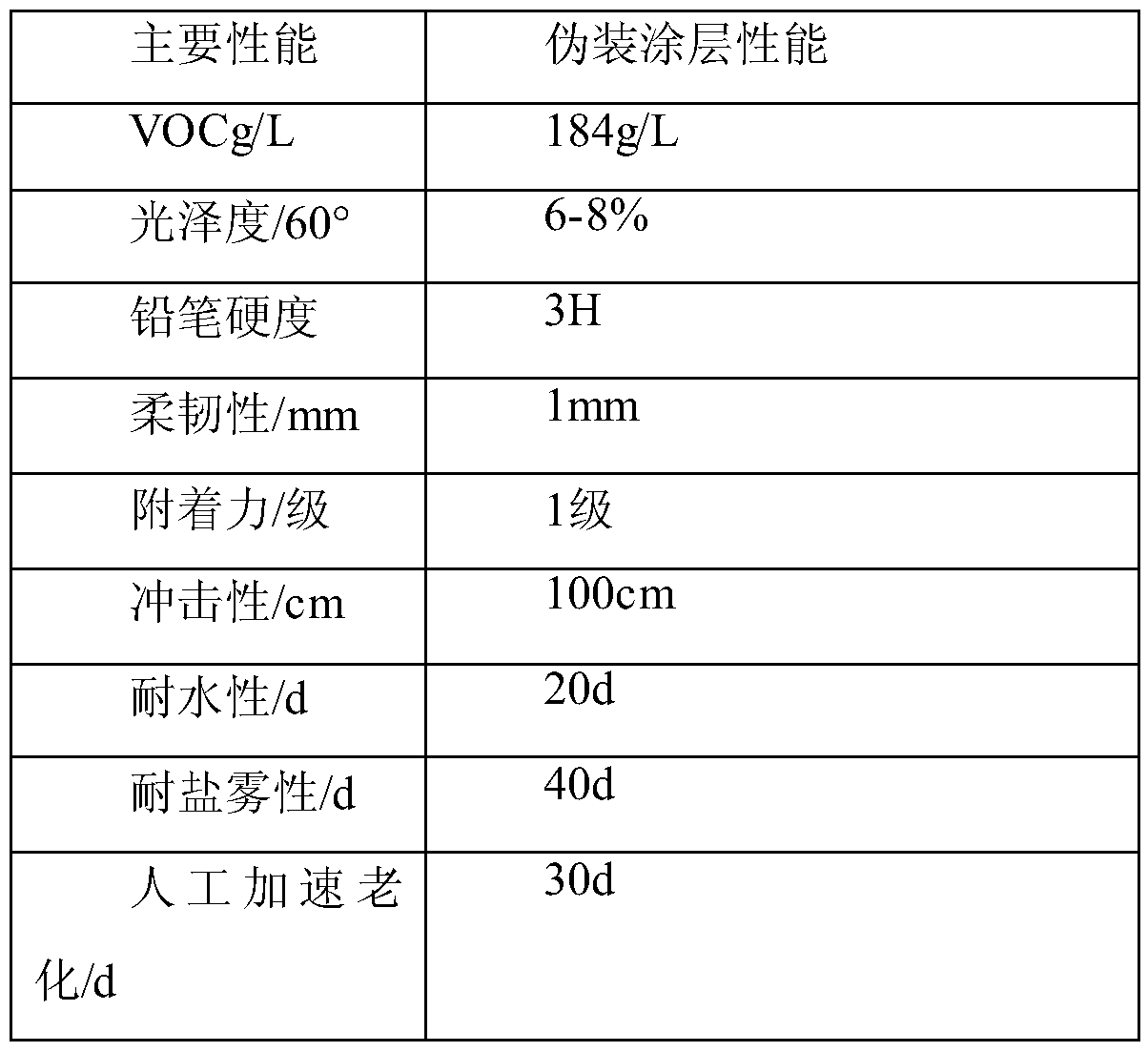

[0057]Stir and mix 25 parts of Bayhydrolxp2470 emulsion, defoamer BYK-011, leveling agent BYK-381, wetting agent TEGOWet280, thickener TEGOViscoPlus3010, and dispersant BYK-190, and then add 8 parts of inorganic green Pigment HEUCODURGreen5G, 3 parts of inorganic yellow pigment HEUCODURYellow255, 2 parts of inorganic black pigment HEUCODURBlack9-100, 2 parts of inorganic blue pigment HEUCODURBlue545, 3 parts of talcum powder, 3 parts of light calcium carbonate, 3 parts of precipitated barium sulfate And 1 part of fumed silica, add 20 parts of distilled water, stir well, use a conical mill to fully grind and disperse, add 10 parts of curing agent Bayhydurxp2547, and get an environmentally friendly two-component waterborne polyurethane camouflage paint. The main properties of the coating are shown in Table 1.

Embodiment 2

[0059] Mix 32 parts of Wanhua 2042 emulsion, defoamer BYK-011, leveling agent TEGOGlide450, wetting agent TEGOTwin4100, thickener TEGOViscoPlus3030, dispersant 0.5 parts of TEGODispers715w, and then add 10 parts of inorganic green pigment HEUCODURGreen654 , 4 parts of inorganic yellow pigment HEUCODURYellow255, 3 parts of inorganic black pigment HEUCODURBlack9-100, 3 parts of inorganic blue pigment HEUCODURBlue5-100, 4 parts of talcum powder, 4 parts of light calcium carbonate, 4 parts of precipitated barium sulfate And 3 parts of fumed silica, add 30 parts of distilled water, stir well, use a conical mill to fully grind and disperse, add 13 parts of curing agent Bayhydurxp2547, and obtain an environmentally friendly two-component water-based polyurethane camouflage paint.

Embodiment 3

[0061] Mix 28 parts of Wanhua 2042 emulsion, defoamer BYK-021, leveling agent TEGOGlide450, wetting agent TEGOTwin4100, thickener TEGOViscoPlus3030, dispersant 0.4 parts of TEGODispers755w, and then add 9 parts of inorganic green pigment HEUCODURGreen654 , 2 parts of inorganic yellow pigment HEUCODURYellow255, 1.5 parts of inorganic black pigment HEUCODURBlack9-100, 1.5 parts of inorganic blue pigment HEUCODURBlue5-100, 5 parts of talcum powder, 5 parts of light calcium carbonate, 2 parts of precipitated barium sulfate And 1 part of fumed silica, add 28 parts of distilled water, stir well, use a conical mill to fully grind and disperse, add 12 parts of curing agent Wanhua 161, and then get an environmentally friendly two-component water-based polyurethane camouflage paint.

[0062] Table 1 Main properties of two-component water-based camouflage paint

[0063]

[0064] The prepared coating is a dark green camouflage coating, and its color is basically the same as that of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com