Enhancement-type inorganic diaphragm for lithium ion battery and preparation method of enhancement-type inorganic diaphragm

A lithium-ion battery, inorganic separator technology, applied in secondary batteries, battery pack parts, separators/films/diaphragms/spacers, etc., can solve the problem of lack of mechanical strength and flexibility, poor adhesion of inorganic particles , Unable to meet the requirements of lithium-ion battery assembly and use, to achieve the effect of improving mechanical strength and flexibility, high flexibility, excellent electrolyte wettability and high temperature dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0036] Polyvinylidene fluoride (PVDF), polyacrylonitrile (PAN) and their mixture (PVDF / PAN) with a mass ratio of 1:1 were dissolved in N,N-dimethylformamide at 80 °C to obtain spinning The mass of the polymer in the spinning solution is 22 parts, and the solvent is 78 parts.

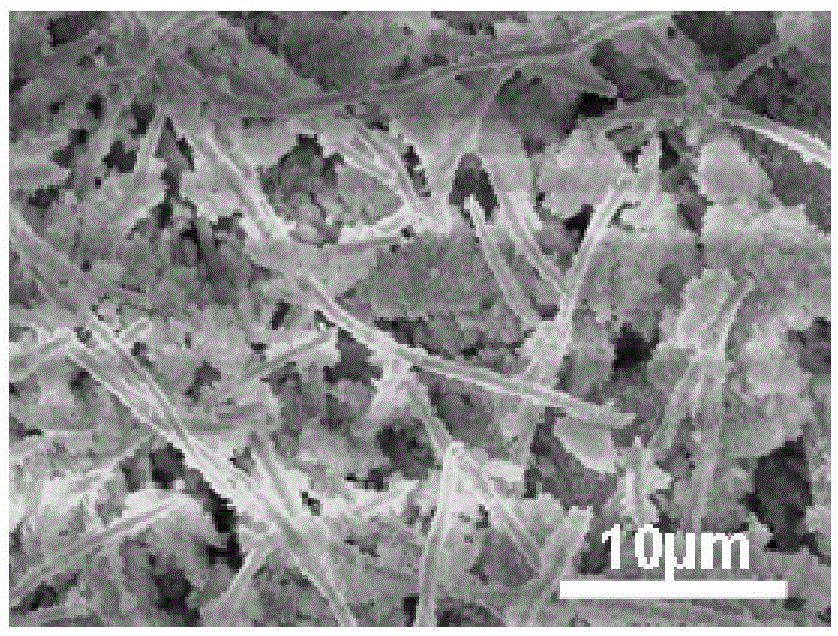

[0037] The above spinning solution was electrospun to prepare polymer nanofibers; the spinning voltage was 15kV.

[0038] Disperse 0.4 parts by mass of nano-silica in 99.6 parts by mass of acetone, and add 0.04 parts by mass of polyvinylidene fluoride as a binder to prepare a nano-silica suspension, ultrasonically treated for 10min .

[0039] The nano-silica suspension is infiltrated into the polymer nanofibers by means of vacuum filtration, and the mass ratio of the nano-silica suspension to the polymer nanofibers is 500, thus obtaining a reinforced inorganic diaphragm.

[0040] After drying, the reinforced inorganic diaphragm was prepared into a dumbbell-shaped sample, and the tensile strength and el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com