Magnetic conductive medium structure and stator disc and coreless disc-type motor having same

A technology of a magnetic conductive medium and a disc motor, applied in the field of mechanical motors, can solve the problems of increasing the length of the air gap of the motor, complicated manufacturing process, increasing the torque ripple of the motor, etc., so as to improve the magnetic field density of the air gap, reduce the manufacturing cost, The effect of reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Please refer to Figure 4A and Figure 4B , respectively, are the top view and the left partial enlarged view of the stator disk with the magnetic conductive medium structure provided in the embodiment of the present invention, and refer to Figure 4C and Figure 4D , respectively are the mechanical characteristic curve diagram and the motor efficiency curve diagram of the stator disk motor with the magnetic conductive medium structure provided in the embodiment of the present invention.

[0043] The stator disk (2) in this embodiment includes:

[0044] Axle hole (21);

[0045] the substrate (22), in this embodiment, 12 pairs of mounting positions (24) are evenly arranged on the surface of the substrate (22) with a phase difference of 30 degrees, and the mounting positions (24) may be grooves or through holes;

[0046] A magnetically conductive medium structure (1), in this embodiment, the magnetically conductive medium structure (1) is located on two surfaces of th...

Embodiment 2

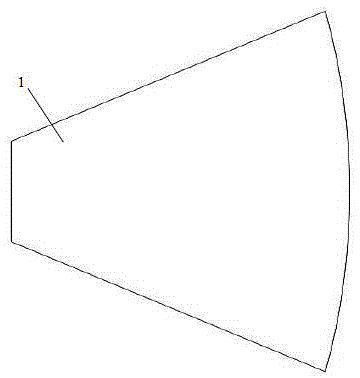

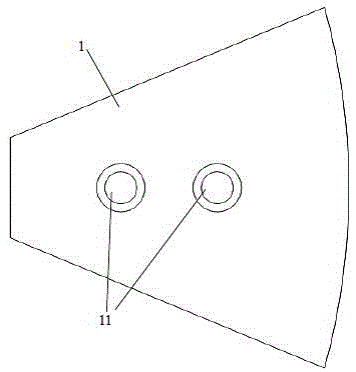

[0053] Please refer to Figure 5A and Figure 5B , which are a top view and a left side view of the stator disk with the magnetic conductive medium structure provided in the embodiment of the present invention, respectively.

[0054] The stator disk described in this embodiment includes:

[0055] Axle hole (21);

[0056] substrate (22);

[0057] The magnetic conductive medium structure (1), in this embodiment, the magnetic conductive medium structure (1) is located on the same side of the substrate, the material is a soft magnetic composite material, and the shape is sector-shaped, and the mutually independent magnetic conductive medium structures (1) are The 30-degree phase difference is sequentially installed on the same side of the base plate (22) of the stator disc (2), and is pasted and fixed on the base plate by glue;

[0058] The coil winding (23), in this embodiment, the coil winding (23) adopts enameled round wire, the bare wire diameter is 0.55mm, each phase has ...

Embodiment 3

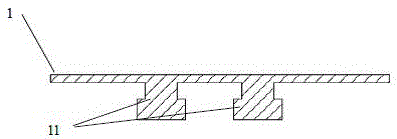

[0061] See Image 6 , which is a plan view of the stator disk with the magnetic conductive medium structure provided in the embodiment of the present invention.

[0062] The stator disk described in this embodiment includes:

[0063] Axle hole (21);

[0064] The base plate (22), in this embodiment, nine pairs of mounting positions are evenly arranged on the surface of the base plate with a phase difference of 40 degrees, and the mounting positions may be grooves or through holes;

[0065] A magnetic conductive medium structure (1), in this embodiment, the magnetic conductive medium structure (1) is located on the same side of the substrate (22), the material is a soft magnetic composite material, and the shape is sector-shaped, each of the magnetic conductive medium structure (1) ) with 2 protruding step-type fixed positions, the mutually independent magnetic conductive medium structures (1) are sequentially installed on the same side of the stator plate (2) base plate (22) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com