Normal-temperature desulfurization dearsenic agent and preparation method thereof

A technology of desulfurization and dearsenic, by weight, applied in separation methods, chemical instruments and methods, refining hydrocarbon oil, etc. The effect of increasing the chance of interface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

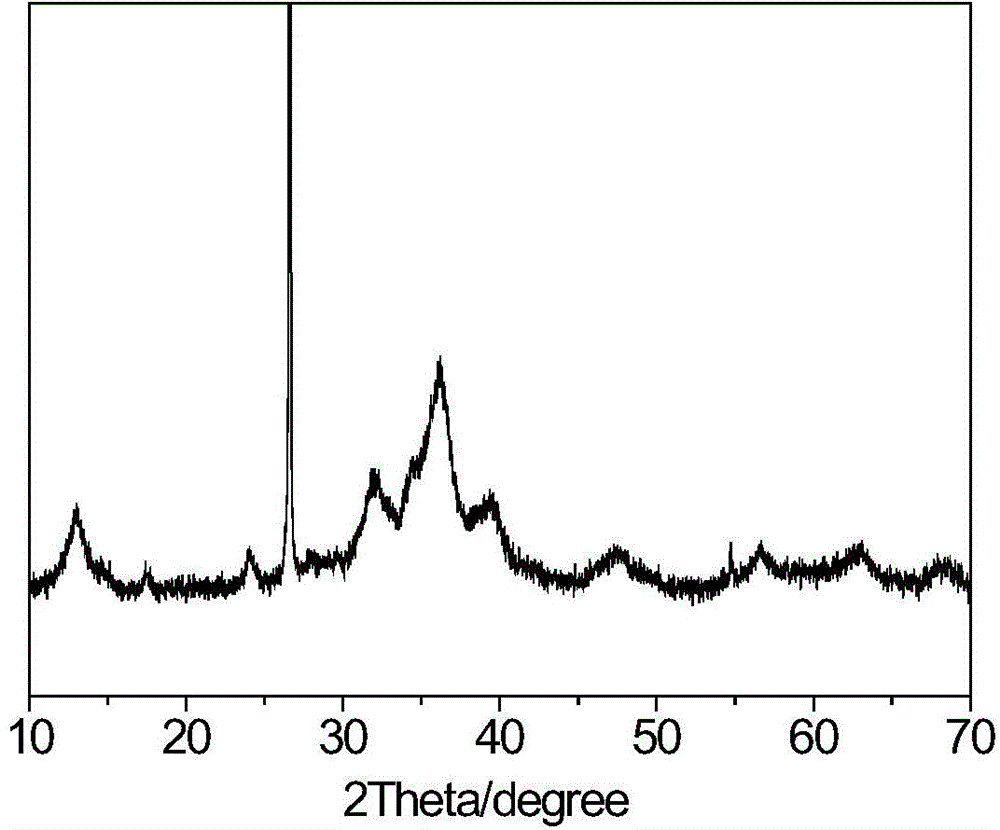

Image

Examples

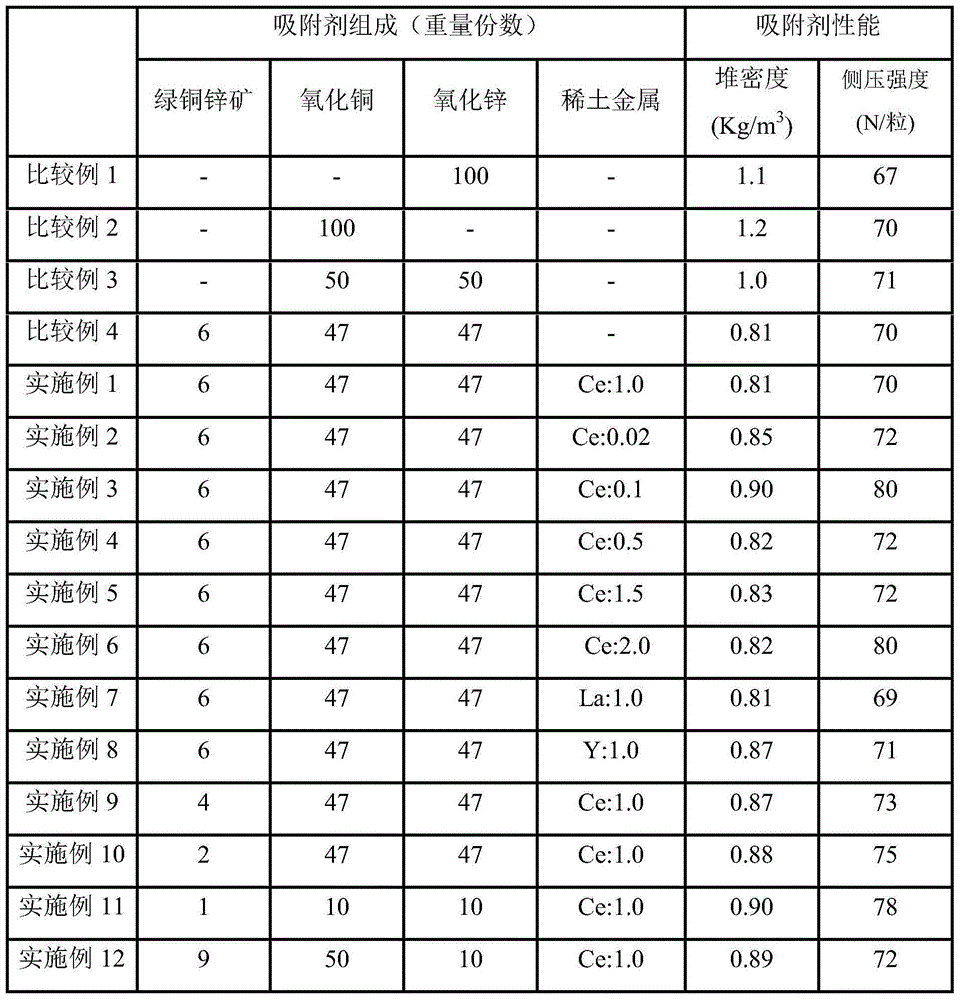

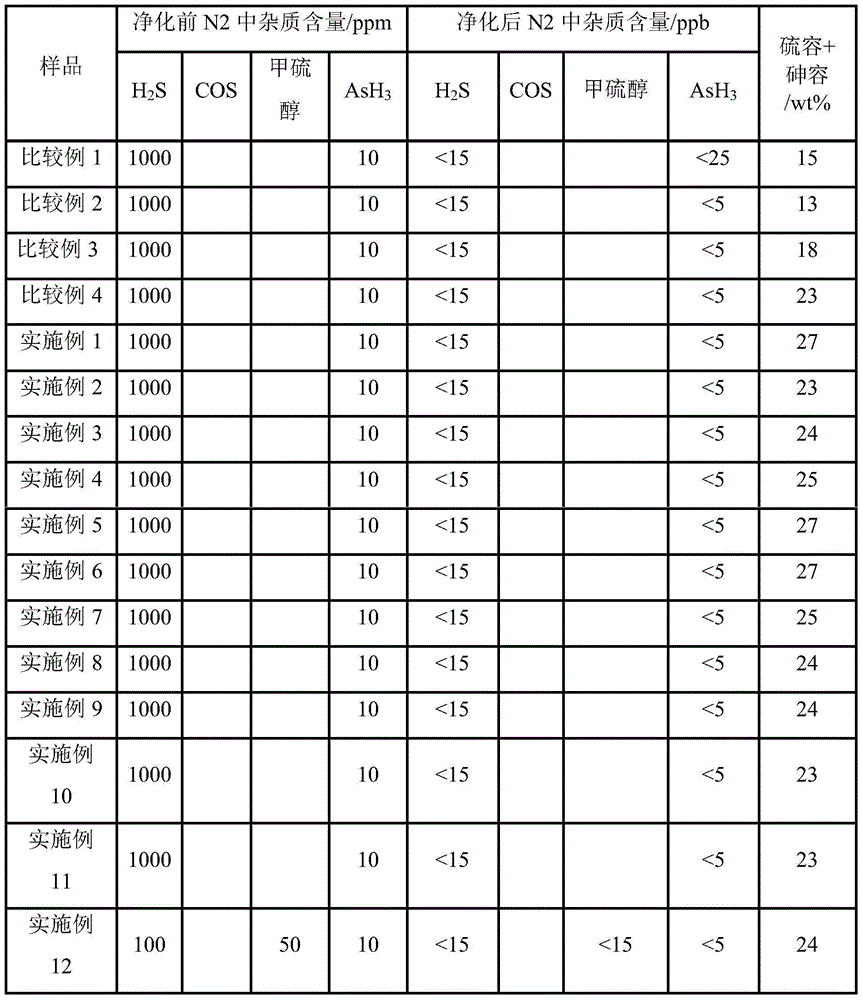

Embodiment 1

[0034] 30 kilograms of copper nitrate, 40 kilograms of zinc nitrate, 10 kilograms of aluminum nitrate, 1.0 kilogram of cerium nitrate and 500 kilograms of water are mixed and stirred to obtain a metal salt solution, and 30 kilograms of sodium carbonate and 550 kilograms of water are mixed to obtain a sodium carbonate solution. Mix the sodium solution and metal salt solution evenly, react at 70°C for 1 hour, wash and dry the precipitate, then add 6 kg of alumina and 1 kg of graphite, mix and roll, then add 30% by weight of water, granulate, and roast at 270°C After 2 hours, it was pressed into tablets and formed, and the composition of the obtained sample is shown in Table 1.

Embodiment 2

[0036] 30 kilograms of copper nitrate, 40 kilograms of zinc nitrate, 10 kilograms of aluminum nitrate, 0.02 kilogram of cerium nitrate and 500 kilograms of water are mixed and stirred to obtain a metal salt solution, and 30 kilograms of sodium carbonate and 550 kilograms of water are mixed to obtain a sodium carbonate solution. Mix the sodium solution and metal salt solution evenly, react at 70°C for 1 hour, wash and dry the precipitate, then add 6 kg of alumina and 1 kg of graphite, mix and roll, then add 30% by weight of water, granulate, and roast at 270°C After 2 hours, it was pressed into tablets and formed, and the composition of the obtained sample is shown in Table 1.

Embodiment 3

[0038] 30 kilograms of copper nitrate, 40 kilograms of zinc nitrate, 10 kilograms of aluminum nitrate, 0.1 kilogram of cerium nitrate and 500 kilograms of water are mixed and stirred to obtain a metal salt solution, and 30 kilograms of sodium carbonate and 550 kilograms of water are mixed to obtain a sodium carbonate solution. Mix the sodium solution and metal salt solution evenly, react at 70°C for 1 hour, wash and dry the precipitate, then add 6 kg of alumina and 1 kg of graphite, mix and roll, then add 30% by weight of water, granulate, and roast at 270°C After 2 hours, it was pressed into tablets and formed, and the composition of the obtained sample is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com