Preparation method of high-fatigue-resistance waste PET plastic modified rubber asphalt concrete

A technology of asphalt concrete and modified rubber, applied in the field of asphalt concrete, can solve problems such as insufficient anti-fatigue ability, and achieve the effect of changing acid-base characteristics, being beneficial to environmental protection and alleviating white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

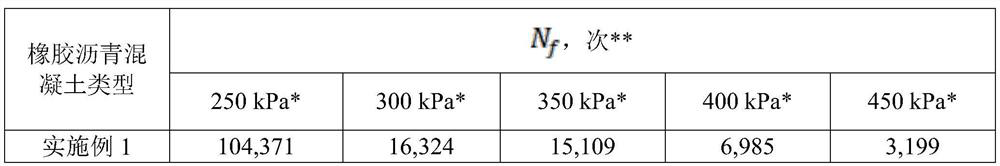

Examples

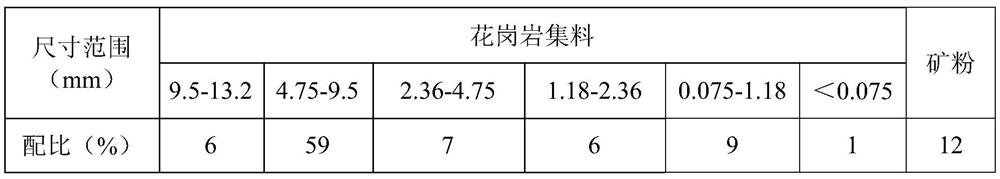

Embodiment 1

[0026] The waste PET plastic-based additive used in this example is a purified product of ammonia degradation of the waste PET plastic. The preparation method is as follows: after the waste PET plastic is broken into flakes, it is mixed with triethylenetetramine solvent according to the mass ratio of 1:2 , reacted at 150 °C for 2 h, and then immediately poured the reaction product into tap water at room temperature, followed by vacuum filtration, repeated water washing, low-temperature drying at 25 °C-35 °C and mechanical grinding to obtain powdery waste PET plastics base additives.

[0027] The concrete preparation method of the high fatigue-resistant waste PET plastic modified rubber asphalt concrete of the present embodiment is:

[0028] 1) Preheating the rubber powder at 120°C, keeping the temperature for at least 30 minutes, then mixing the above-mentioned rubber powder and base asphalt at 180°C, shearing at 3500 rpm for 1 hour, to obtain tire rubber powder modified aspha...

Embodiment 2

[0042] The difference between this example and Example 1 is that the content of the waste PET plastic-based additive is 2% of the mass of the tire rubber powder modified asphalt.

[0043] According to the "Asphalt and Asphalt Mixture Test Regulations for Highway Engineering" (JTGE20-2011), the rutting test and the stability test were carried out on the high-fatigue-resistant waste PET plastic modified rubber asphalt concrete in this example.

[0044] It can be seen from the test that the rut depth of the high-fatigue waste PET plastic modified rubber asphalt concrete in this example is 3.71mm at 60°C, the Marshall specimen stability is 12.43kN, and the flow value is 25.5mm.

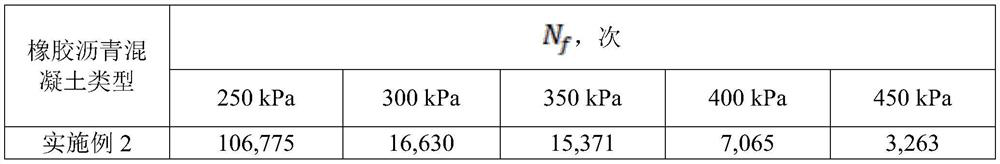

[0045] The indirect tensile fatigue test was carried out on the high-fatigue-resistant waste PET plastic modified rubber asphalt concrete in this example, and the results are shown in Table 3.

[0046] table 3

[0047]

[0048] It can be seen from the above test results that, in comparison with Exampl...

Embodiment 3

[0050] The difference between this example and Example 1 is that the amount of the waste PET plastic-based additive is 3% of the mass of the tire rubber powder modified asphalt.

[0051] According to the "Asphalt and Asphalt Mixture Test Regulations for Highway Engineering" (JTGE20-2011), the rutting test and the stability test were carried out on the high-fatigue-resistant waste PET plastic modified rubber asphalt concrete in this example.

[0052] It can be seen from the test that the rut depth of the high-fatigue waste PET plastic modified rubber asphalt concrete in this example is 3.76mm at 60°C, the Marshall specimen stability is 12.41kN, and the flow value is 24.9mm.

[0053] The indirect tensile fatigue test was carried out on the high-fatigue-resistant waste PET plastic modified rubber asphalt concrete in this example, and the results are shown in Table 4.

[0054] Table 4

[0055]

[0056] It can be seen from the above test results that under the same level of tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com