A pt@sio with yolk‑eggshell structure 2 Catalyst preparation method

A catalyst and eggshell technology, which is applied in the field of preparation of Pt@SiO2 catalysts with egg yolk-eggshell structure, can solve the problems that the size of metal particles is difficult to control to the nanometer level with catalytic activity, and the reduction process is not easy to control, achieving excellent Hydrogenation activity, good cycle performance, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of mesoporous silica: Dissolve 0.1g CTAB in 45mL deionized water under stirring at 70°C, add 0.35mL NaOH (2M), and stir for 0.5h. Add 0.3mL of trimethylbenzene, sonicate for 1h to form a white emulsion. Under stirring, add 0.5mLTEOS, add 0.4mL ethyl acetate after precipitation, and stir for 1-2h. The mixture was transferred to a crystallization kettle and crystallized at 100°C for 24h. After cooling, the product was filtered with suction, washed with water and ethanol, and after drying, it was stirred with an absolute ethanol solution containing ammonium nitrate at 60°C for 0.5h, filtered with suction, washed with alcohol, and dried to obtain a white light powder (hydrophilic Materials, the ratio of benzene to water is 0.3, Chemical Communication, 2014, volume 50, page 10830).

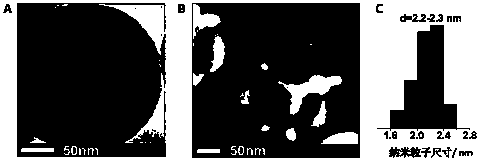

[0039] 80mg of the above-mentioned mesoporous silica material was dispersed in 4mL of Pt nanoparticle aqueous solution, and ultrasonically adsorbed for 1-3h. Electron m...

Embodiment 2

[0041] The preparation process of Example 1 is adopted, and the difference is that the amount of adding the nanoparticle aqueous solution is 20 mL, without dilution. Electron microscope pictures show that the nanoparticles are evenly distributed on the inner core ( Figure 5 ). ICP characterizes that the metal content is 5% (mass fraction).

Embodiment 3

[0043] The preparation method of mesoporous silica: adopt the preparation process of Example 1, the difference is that, add 0.5mLTEOS, 0.4mL ethyl acetate, add 0.33mL propyltrichlorosilane after 5-10 minutes, and get the inner core as propyl (Propyl) modified mesoporous silica spheres. (hydrophobic material, benzene-to-water ratio is 1.8, Chemical Communication, 2014, volume 50, page 10830).

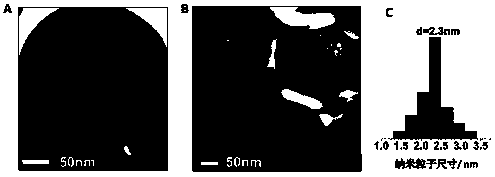

[0044] The preparation method of the egg yolk eggshell structure catalyst is the same as in Example 1. Electron microscope pictures show that the obtained product is a silica pellet with egg yolk-eggshell type. Pt nanoparticles are distributed in the inner core and cavity, with good dispersion and uniform particle size, with a size of about 2.3nm ( Image 6 ). Its catalytic hydrogenation reaction activity is shown in Figure 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com