Production method for low-carbon acetate

A production method and low-carbon ester technology, which is applied in the field of low-carbon acetate production, can solve problems such as few reports, and achieve the effects of less by-products, high activity, and low equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

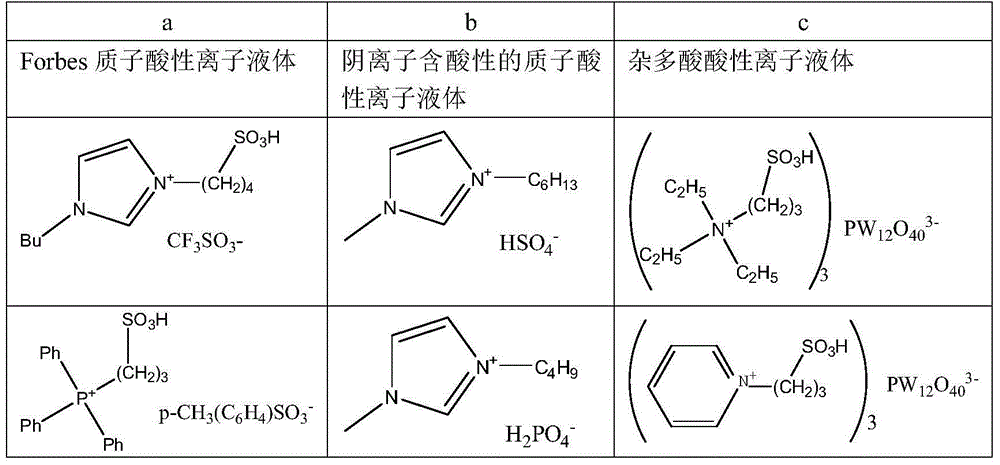

AI Technical Summary

Problems solved by technology

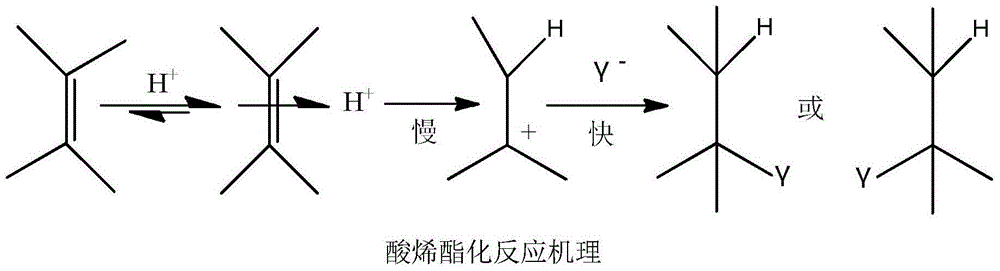

Method used

Image

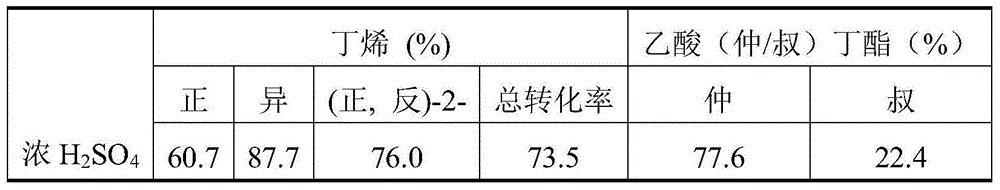

Examples

Embodiment 1

[0042] Acidic ionic liquid [BSN 222 ][H 2 PW 12 o 40 ] is the catalyzer of acetic acid-butene addition esterification. where BSN 222 For triethyl butyl ammonium sulfonate. Add 0.5g of [BSN 222 ][H 2 PW 12 o 40 ], acetic acid 5ml, tighten the lid of the kettle to form a closed space. Start the stirrer with a rotating speed of 1000r / min. Turn on the feed gas sampling pump, set the sampling rate to 500ml / h, and add 15ml of liquefied gas containing 28.6wt% olefins. Set the temperature of the circulating oil bath to 90°C, and start timing when the thermometer in the reactor reaches the set temperature, and the reaction time is 4 hours. After the reaction time reaches 4 hours, stop stirring and heating, and continue to stand still for 15 minutes after the reaction kettle is naturally cooled to room temperature. The exhaust gas is then collected with an air bag to ensure that all the gas is collected in one air bag. The liquid part was washed repeatedly with water, ether...

Embodiment 2

[0048] With acidic ionic liquid [Ph 3 PSO 3 H][HSO 4 ] is the catalyzer of acetic acid-butene addition esterification. The amount of catalyst was 3.62 g. The reaction steps are the same as in Example 1. The conversion rate of each olefin component, the total olefin conversion rate and the selectivity of sec-butyl acetate are shown in Table 4.

[0049] Table 4

[0050]

Embodiment 3

[0052] Acidic ionic liquid [BSN 222 ] 3 [PW 12 o 40 ] is the catalyzer of acetic acid-butene addition esterification. The amount of catalyst is [BSN 222 ] 3 [PW 12 o 40 ] 0.5g. The reaction steps are the same as in Example 1. The conversion rate of each olefin component, the total olefin conversion rate and the selectivity of sec-butyl acetate are shown in Table 5.

[0053] table 5

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com