Method for coating polymeric microsphere with carbon nano tube

A technology of carbon nanotubes and polymers, applied in the direction of coating, etc., can solve the problems of high price, complicated equipment, shortage of resources, etc., and achieve the effect of low cost, simple preparation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

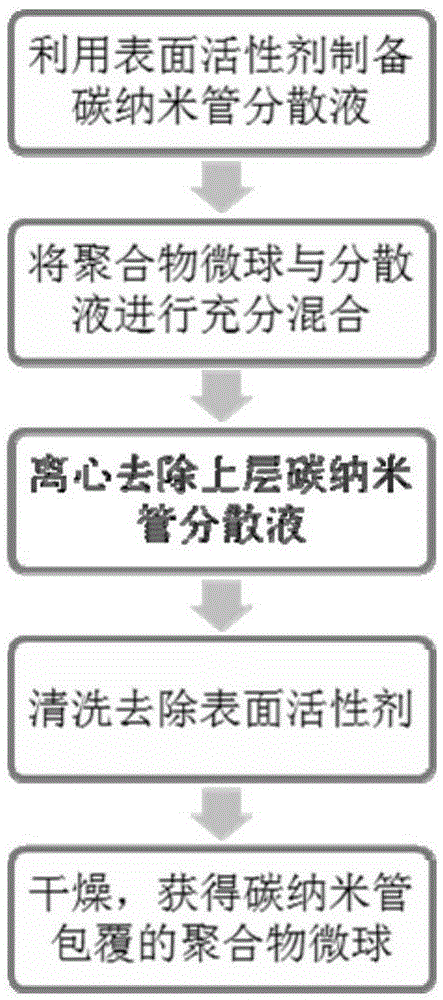

Method used

Image

Examples

Embodiment 1

[0031] In the present embodiment, the method of carbon nanotube coating polymer microsphere is as follows:

[0032] 1) Using sodium lauryl sulfate to disperse single-walled carbon nanotubes in deionized water under the action of ultrasonic waves, and then centrifuge to obtain the supernatant to obtain a single-walled carbon nanotube dispersion with a concentration of 0.1 mg / ml.

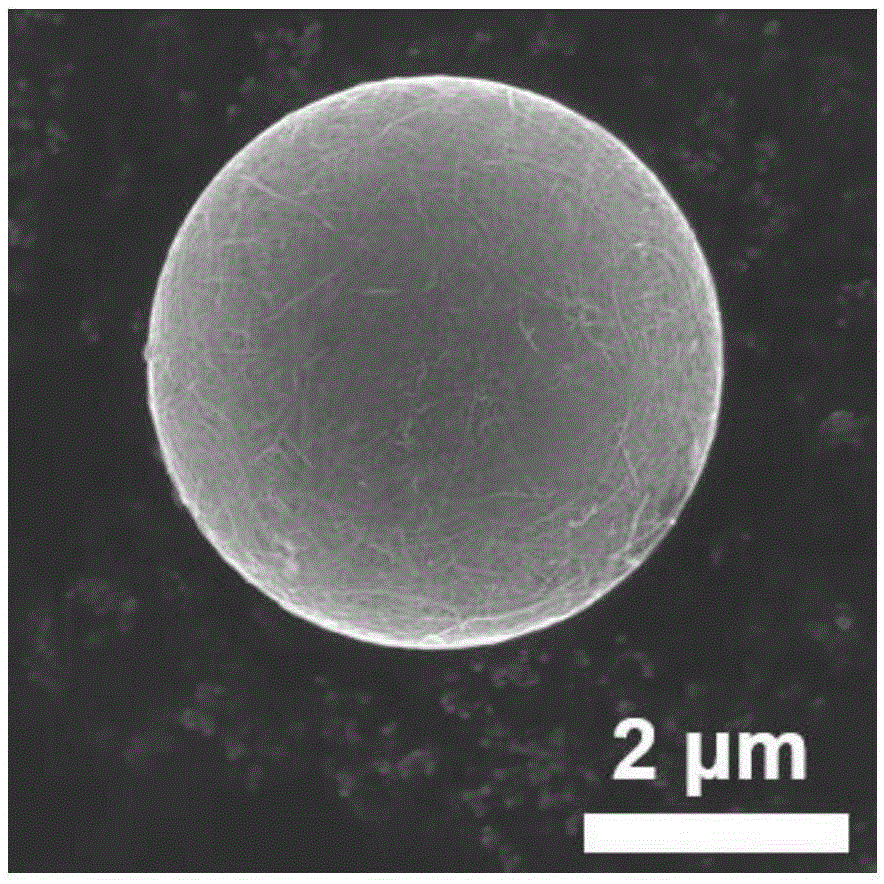

[0033] 2) Add polystyrene and polymethyl methacrylate composite microspheres with a diameter of 5 μm into the single-walled carbon nanotube dispersion and mix evenly. The mass ratio of composite microspheres to carbon nanotubes is 500:3. The mass ratio of polystyrene to polymethyl methacrylate in the ball is 1:1.

[0034] 3) Centrifuge the mixed solution at a speed of 10,000 r / min for 30 minutes, remove the upper dispersion liquid, and obtain polymer microspheres coated with single-walled carbon nanotubes.

[0035] 4) Washing the obtained microspheres with deionized water and ethanol in turn to remov...

Embodiment 2

[0038] The difference from Example 1 is that the method of coating polymer microspheres with carbon nanotubes in this example is as follows:

[0039] 1) Using sodium lauryl sulfate to disperse the double-walled carbon nanotubes in deionized water under the action of ultrasonic waves, and then take the supernatant through centrifugation to obtain a double-walled carbon nanotube dispersion with a concentration of 0.025 mg / ml.

[0040] 2) Add polyethylene microspheres with a diameter of 0.5 μm into the double-walled carbon nanotube dispersion and mix evenly, and the mass ratio of polyethylene microspheres to carbon nanotubes is 500:3.

[0041] 3) Centrifuge the mixed solution at a speed of 2000 r / min for 10 minutes, remove the upper dispersion liquid, and obtain polyethylene microspheres coated with carbon nanotubes.

[0042] 4) Wash the obtained microspheres with deionized water, isopropanol, and a mixed solvent with a volume ratio of water and isopropanol of 2:1 in sequence to ...

Embodiment 3

[0045] The difference from Example 1 is that the method of coating polymer microspheres with carbon nanotubes in this example is as follows:

[0046] 1) Use sodium dodecylsulfonate to disperse multi-walled carbon nanotubes with a diameter of 20nm in deionized water under the action of ultrasonic waves, and then take the supernatant through centrifugation to obtain multi-walled carbon nanotubes with a concentration of 0.1mg / ml nanotube dispersion.

[0047] 2) Add polypropylene microspheres with a diameter of 5 μm into the multi-walled carbon nanotube dispersion and mix evenly. The mass ratio of polypropylene microspheres to carbon nanotubes is 500:3.

[0048] 3) Centrifuge the mixed solution at a rotational speed of 5000 r / min for 20 minutes, remove the upper dispersion liquid, and obtain polymer microspheres coated with multi-walled carbon nanotubes.

[0049] 4) Washing the obtained microspheres with ethanol and deionized water in turn to remove excess surfactant.

[0050] 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com