Modified asphalt composition particle and preparation method thereof

A technology of modified asphalt and composition, applied in the field of petroleum asphalt, can solve problems such as increasing the difficulty of asphalt dispersion, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

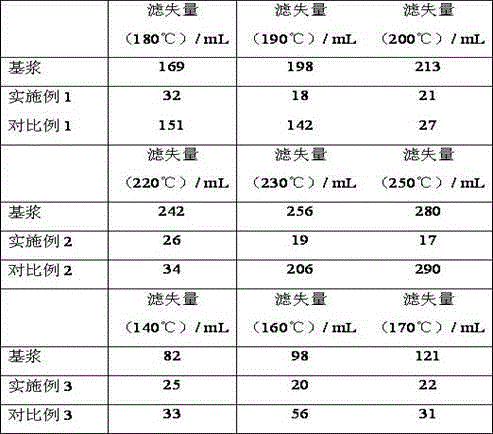

Embodiment 1

[0045] (1) Mix high softening point asphalt I (softening point is 200°C) with kerosene to obtain mother liquor I (mixing mass ratio is 2:1), and then spray mother liquor I evenly on rubber powder particles (mass ratio of mother liquor to rubber powder particles 1:1), after static permeation for 2 hours, then remove the compatibilizer under vacuum conditions (temperature 80°C, pressure ≤ 8kPa, time 2 hours), and the remaining materials are frozen (freezing temperature -35°C, frozen time is 12 hours), pulverized to obtain modified rubber powder particles.

[0046] (2) Take 100g of high softening point asphalt II (softening point of 180°C) and 70g of kerosene in a container, stir at room temperature (25°C) for 30 minutes, and mix thoroughly to obtain mother liquor II; mix 60g of modified rubber powder The granules are mixed with the mother liquor II in the reactor, and compressed air is introduced into it, the gas inlet pressure is 0.15MPa, the reactor temperature is kept at 180~...

Embodiment 2

[0049] (1) Mix high softening point asphalt I (softening point is 250°C) with diesel oil to obtain mother liquor I (mixing mass ratio is 1:1), and then spray mother liquor I evenly on rubber powder particles (mass of mother liquor and rubber powder particles The ratio is 2:1), after static infiltration for 4 hours, then remove the compatibilizer under vacuum conditions (temperature 100°C, pressure ≤ 8kPa, time 1 hour), and the remaining materials are frozen (freezing temperature -25°C, frozen time is 10 hours), pulverized to obtain modified rubber powder particles.

[0050] (2) Take 100g of high softening point asphalt II (softening point of 220°C) and 50g of diesel oil in a container, stir at room temperature 50°C for 30 minutes, and mix thoroughly to obtain mother liquor II; mix 100g of modified rubber powder particles with The mother liquor II is mixed in the reactor and fed with compressed air, the gas inlet pressure is 0.25MPa, the reactor temperature is maintained at 230...

Embodiment 3

[0053] (1) Mix high softening point asphalt I (softening point: 140°C) with gasoline to obtain mother liquor I (mixing mass ratio is 3:1), and then spray mother liquor I evenly on rubber powder particles (mass of mother liquor and rubber powder particles The ratio is 3:1), after standing for infiltration for 1 hour, then remove the compatibilizer under vacuum conditions (temperature 50°C, pressure ≤ 8kPa, time 1.5 hours), and the remaining materials are frozen (freezing temperature -30°C, frozen time is 8 hours), crushed to obtain modified rubber powder particles.

[0054] (2) Take 100g of high softening point asphalt II (softening point of 170°C) and 100g of gasoline in a container, stir at room temperature at 80°C for 35 minutes, and mix thoroughly to obtain mother liquor II; mix 120g of modified rubber powder particles with The mother liquor II is mixed in the reactor and fed with compressed air, the gas inlet pressure is 0.3MPa, the reactor temperature is kept at 150~160°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com