Beta-type Zr-Nb-Si biomedical alloy and preparation method thereof

A zr-nb-si biomedical technology, applied in the field of zirconium-based biomedical alloys and its preparation, can solve the problems of long-term stability of unfavorable bone healing implants, insufficient matching of elastic modulus, and easy damage to the human body, etc., to achieve Good development and application prospects, low production cost, good biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

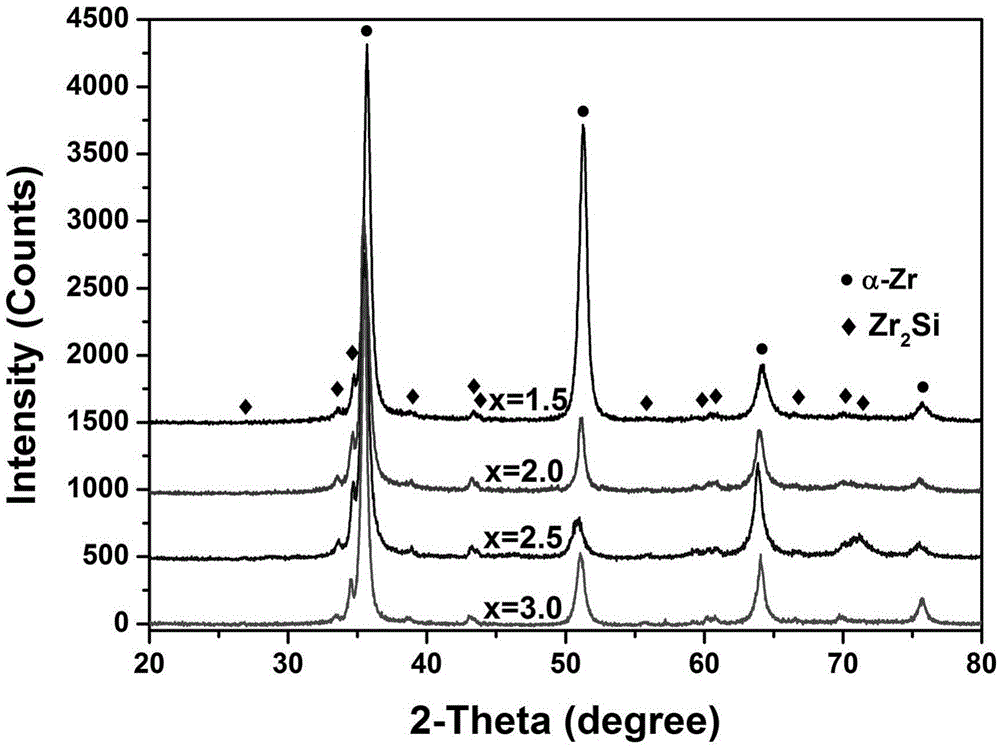

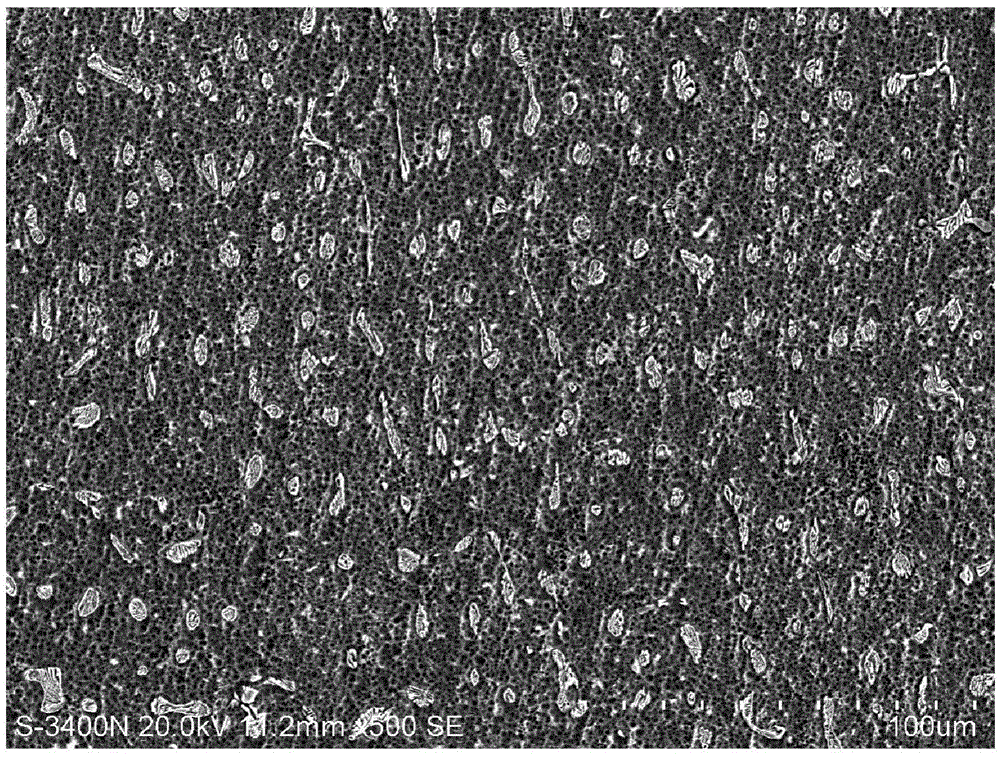

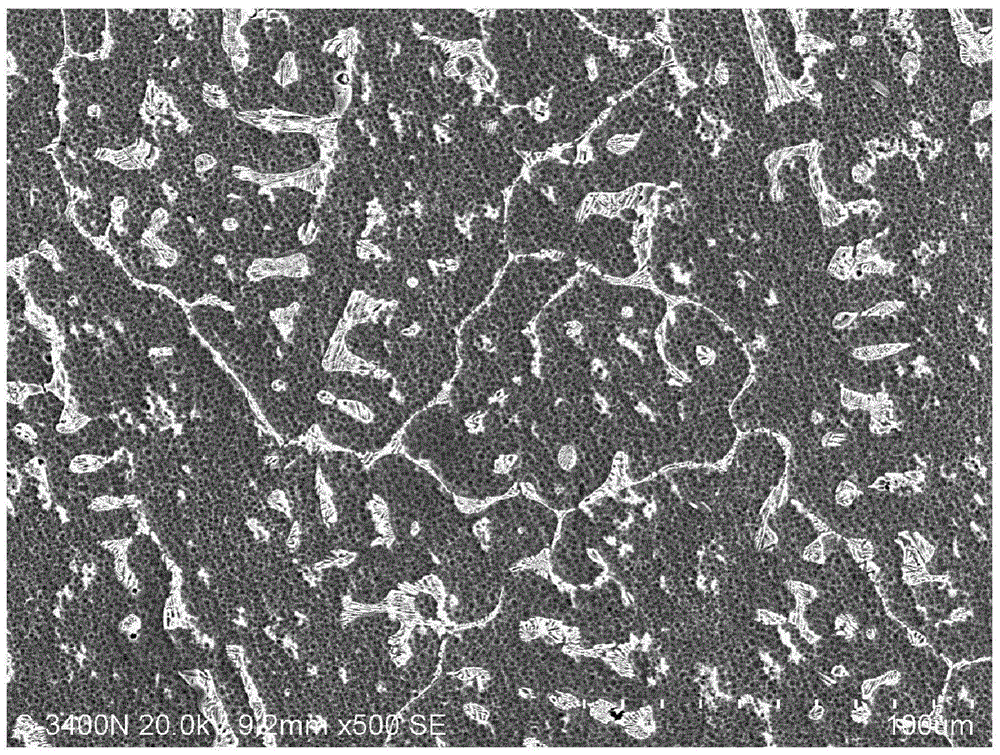

Image

Examples

Embodiment 1

[0033] 1. Raw material formula: raw material components and weight percentages are: sponge zirconium 81.07%, niobium 18.46%, silicon 0.47%; the purity of sponge zirconium, niobium and silicon are all above 99%.

[0034] 2. Preparation method

[0035] (1) Weighing of raw materials, respectively weighing zirconium sponge, niobium and silicon according to the weight percentage of each raw material component; the particle size of raw materials is controlled below 3 cm;

[0036] (2) Mix the raw materials, mix the weighed raw materials evenly by stirring and mixing;

[0037](3) Raw material smelting, put the uniformly mixed raw material into the crucible in the non-consumable vacuum electric arc furnace, and then vacuumize, the vacuum degree is 1×10 -2 ~1×10 -3 Pa; then pass in argon gas for washing; vacuumize and wash repeatedly for 3 times. Finally, melting is carried out under the protection of argon, the melting temperature is 2900-3000°C; the melting voltage is 220V, the mel...

Embodiment 2

[0042] 1. Raw material formula: raw material components and weight percentages are: sponge zirconium 80.85%, niobium 18.53%; silicon 0.62%; the purity of sponge zirconium, niobium and silicon are all above 99%.

[0043] 2. Preparation method

[0044] (1) Weighing of raw materials, respectively weighing zirconium sponge, niobium and silicon according to the weight percentage of each raw material component; the particle size of raw materials is controlled below 3 cm;

[0045] (2) Mix the raw materials, mix the weighed raw materials evenly by stirring and mixing;

[0046] (3) Raw material smelting, put the uniformly mixed raw material into the crucible in the non-consumable vacuum electric arc furnace, and then vacuumize, the vacuum degree is 1×10 -2 ~1×10 -3 Pa; then pass in argon gas for scrubbing; vacuumize and scrub for 2 times. Finally, under the protection of argon, the melting temperature is 2900-3000°C; the melting voltage is 220V, the melting current is controlled at ...

Embodiment 3

[0051] 1. Raw material formula: raw material components and weight percentages are: sponge zirconium 80.63%, niobium 18.59%, silicon 0.78%; the purity of sponge zirconium, niobium and silicon are all above 99%.

[0052] 2. Preparation method

[0053] (1) Weighing of raw materials, respectively weighing zirconium sponge, niobium and silicon according to the weight percentage of each raw material component; the particle size of raw materials is controlled below 3 cm;

[0054] (2) Mix the raw materials, mix the weighed raw materials evenly by stirring and mixing;

[0055] (3) Raw material smelting, put the uniformly mixed raw material into the crucible in the non-consumable vacuum electric arc furnace, and then vacuumize, the vacuum degree is 1×10 -2 ~1×10 -3 Pa; then pass in argon gas for washing; vacuumize and wash repeatedly for 3 times. Finally, under the protection of argon, the melting temperature is 3000-3100°C; the melting voltage is 220V, the melting current is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com