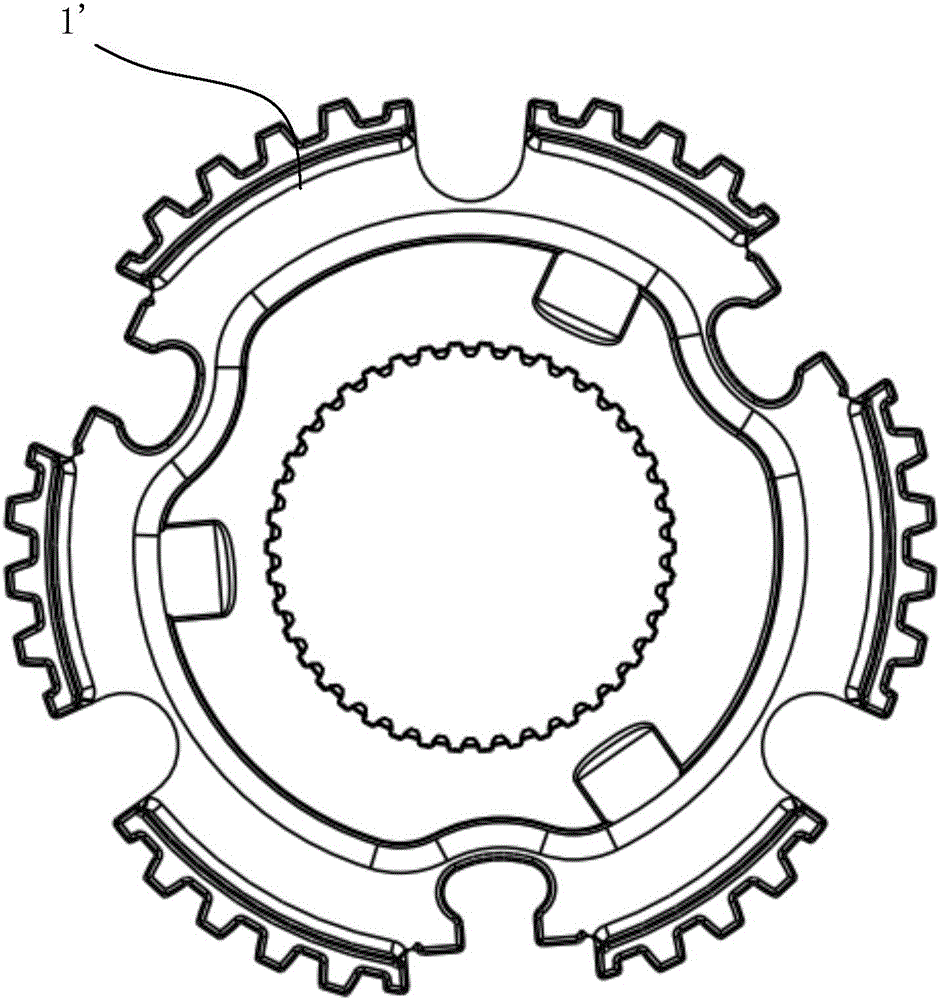

Improved synchronizer gear hub and manufacturing method thereof

A manufacturing method and synchronizer technology, which are applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of increasing the rotational inertia of the transmission system, unreachable gear hubs of synchronizers, complicated manufacturing and processing processes, etc., and achieve a wide range of materials. , The effect of reducing design parameters and machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The improved synchronizer gear hub and its manufacturing method of the present invention, for the redesign of the existing synchronizer gear hub, carry out stress analysis through computer aided engineering (CAE), and then carry out effective structural optimization means, so that the improved synchronizer manufactured Compared with the existing synchronizer gear hub, the synchronizer gear hub has better mechanical properties.

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

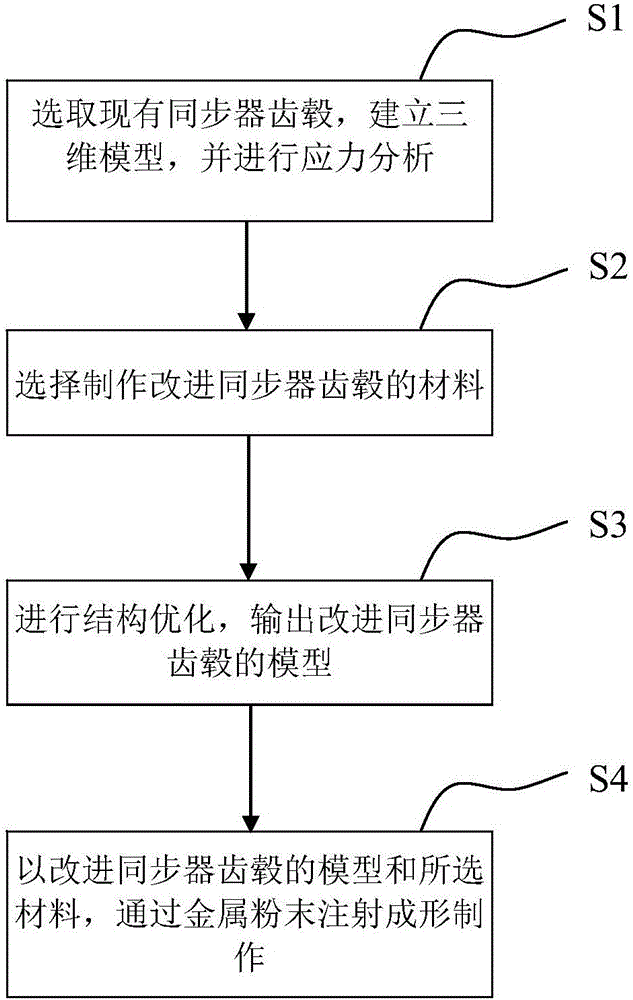

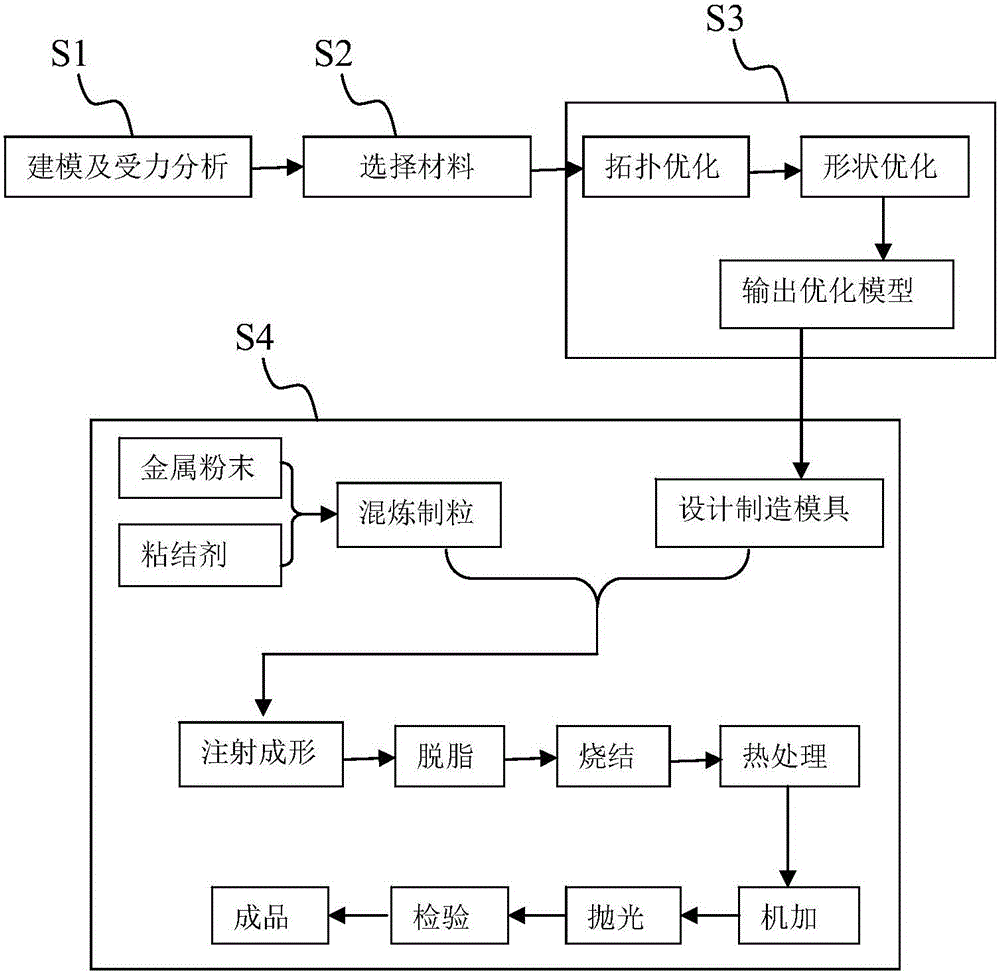

[0043] see figure 2 As shown, it is a schematic flow chart of the steps of a method for manufacturing an improved synchronizer hub of the present invention. Preferably, the method for manufacturing the improved synchronizer hub includes:

[0044] Step one S1, select a synchronizer gear hub (such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com