a mesoporous so 4 2‑ /zro 2 preparation method

A mesoporous, zirconium-based technology is applied in the field of preparation of mesoporous SO42-/ZrO2, which can solve the problems of loss of loaded sulfur species, poor thermal stability of the carrier, easy collapse of the pore structure, etc., and achieves a simple and easy preparation method and improves stability. The effect of the uniform and uniform mesoporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 25mmol ZrCl 4 , 25mmol terephthalic acid, 25mmol concentrated HCl, 5mL 1mol / L H 2 SO 4 Add the solution together to 150mL N,N-dimethylformamide and stir evenly, put it into a 200mL stainless steel reaction kettle with a polytetrafluoroethylene liner, conduct a crystallization reaction at 160°C for 3 days, and take out the obtained white powder. Vacuum drying at 150°C yielded sulfur-containing zirconium-based MOFs material UiO-66-S.

[0025] Put UiO-66-S in a muffle furnace, heat up to 500 °C at a rate of 2 °C / min, and bake for 6 h to obtain mesoporous SO 4 2- / ZrO 2 .

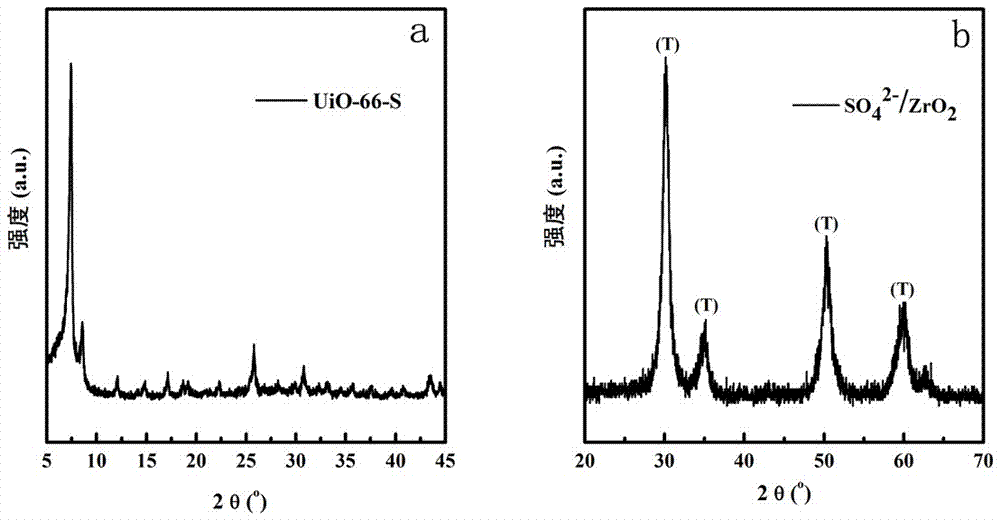

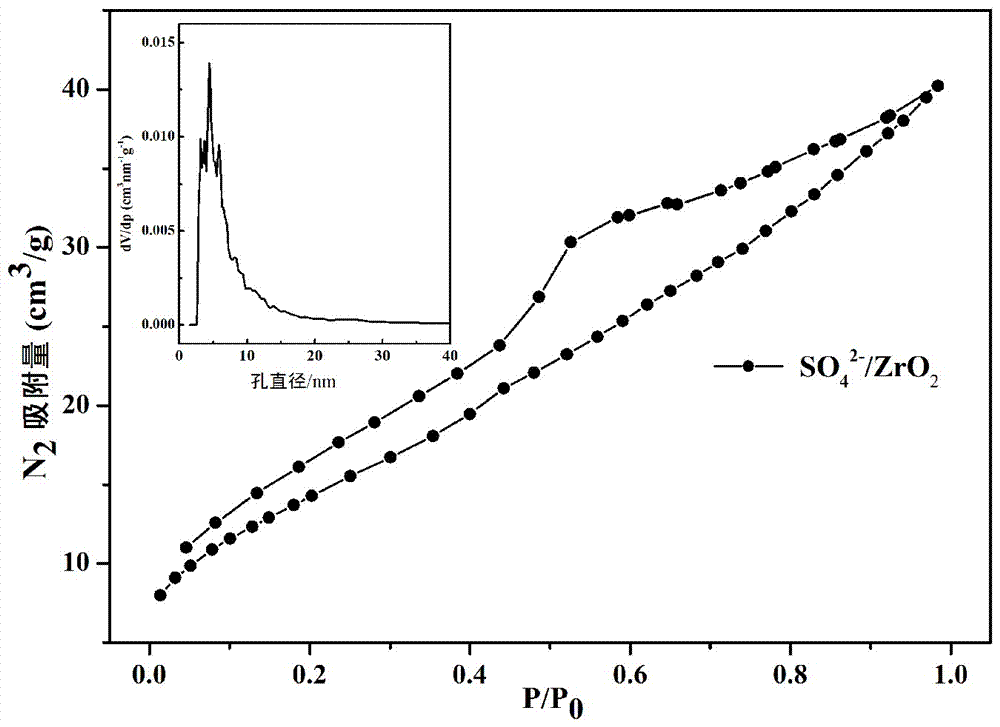

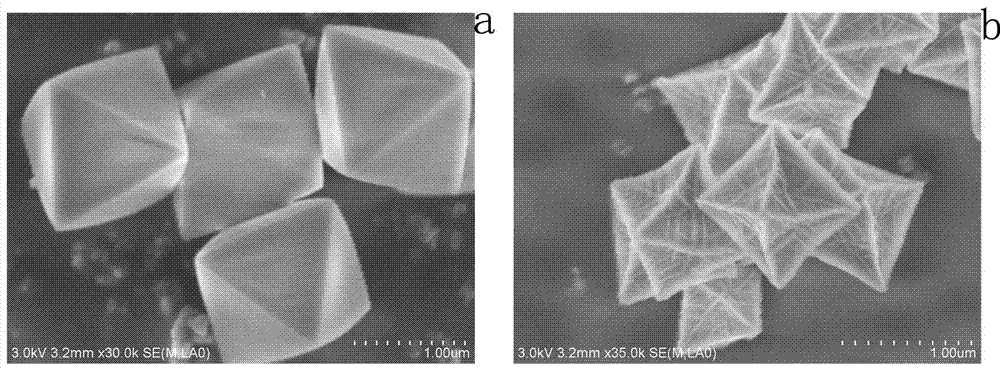

[0026] The prepared samples were characterized by XRD. figure 1 (a) It can be seen that the as-prepared sulfur-containing zirconium-based MOFs material UiO-66-S shows the same properties as UiO-66 reported in the literature [J.H. Cavka, S. Jakobsen, U. Olsbye, N. Guillou, C.Lamberti, S. Bordiga, K.P. Lillerud, J. Am. Chem. Soc. 2008.130. 13850-13851] consistent with the characteristic diffrac...

Embodiment 2

[0030] Take 25mmol ZrCl 4 , 25mmol terephthalic acid, 25mmol concentrated HCl, 5mmol (NH 4 ) 2 SO 4 , added together to 150mL N,N-dimethylformamide and stirred evenly, put into a 200mL stainless steel reaction kettle with a polytetrafluoroethylene liner, crystallize at 160°C for 6 days, take out the obtained white powder, 150 ℃ vacuum drying to obtain the sulfur-containing zirconium-based MOFs material UiO-66-S.

[0031] Put UiO-66-S in a muffle furnace, heat up to 500 °C at a rate of 2 °C / min, and bake for 6 h to obtain mesoporous SO 4 2- / ZrO 2 .

Embodiment 3

[0033] Take 0.227mmol ZrCl 4 , 0.227mmol terephthalic acid, 0.1mL 0.5mol / L H 2 SO 4 Add the solution together to 340mmol N,N-dimethylformamide and stir evenly, put it into a 100mL stainless steel reaction kettle with a polytetrafluoroethylene liner, conduct a crystallization reaction at 200°C for 5 days, and take out the obtained white powder. Vacuum drying at 150°C yielded sulfur-containing zirconium-based MOFs material UiO-66-S.

[0034] Put UiO-66-S in a muffle furnace, heat up to 600 °C at a rate of 2 °C / min, and bake for 6 h to obtain mesoporous SO 4 2- / ZrO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com