Heavy metal curing agent and method for treating heavy metal compound contaminated soil by same

A compound pollution and curing agent technology, applied in the restoration of polluted soil, chemical instruments and methods, soil conditioning materials, etc., can solve the problems of unfavorable fixation, unfavorable fixation of Pb and Cu, etc., and achieve low manufacturing cost and solidification treatment cost Inexpensive, the effect of reducing the risk of toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Preparation of combined curing agent: calcinate shells at 600°C for 4h, peat at 200°C for 2h, pass through a #10 mesh (2mm) sieve, and the pH of shell ash is 11-13, the pH of peat ash is 7.5-8.5, According to the mass percentage of shell ash and peat ash 1:0, 2:1, 2:2, 3:1 or 3:2, add it to the soil to form a weakly alkaline soil environment.

[0019] The method for processing heavy metal compound polluted soil: directly add described combined solidifying agent in the described heavy metal compound polluted soil through pretreatment, the consumption of combined solidifying agent is 5%-25% of the mass of described heavy metal compound polluted soil, is It is lower than or equal to the sum of the maximum percentages after the combination of the two curing agents, and the moisture content is kept at 40%; the mixture after adding the combined curing agent is cured for no less than 14 days to complete the curing process.

[0020] During curing, the mixture is kept sealed dur...

Embodiment 1

[0022] Embodiment 1: The soil used for solidification comes from the former site of a resource regeneration company in a certain city, and the heavy metal Pb in the soil is determined through analysis 2+ (5796ppm), As 5+ (610ppm), Cu 2+ (760ppm) seriously exceeds the standard, as the experimental soil of this example.

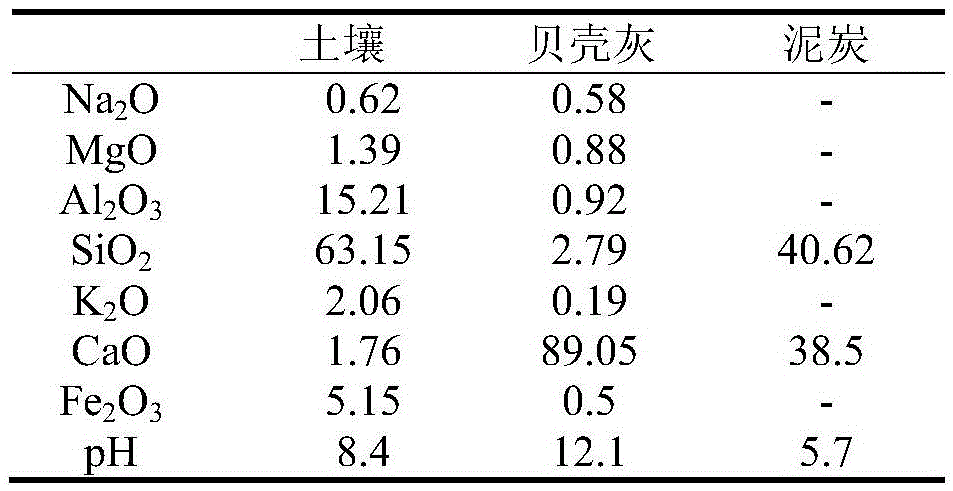

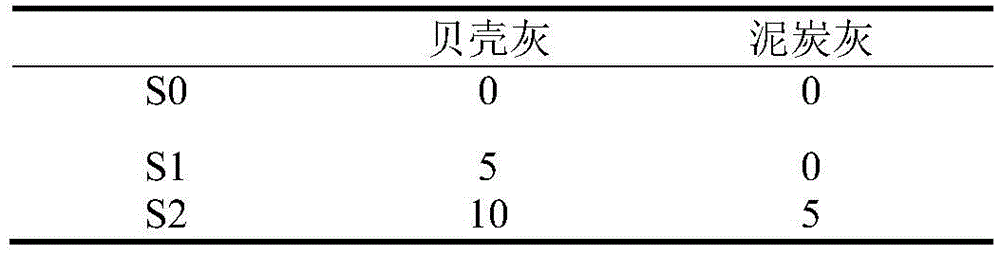

[0023] A heavy metal compound polluted soil solidifying agent of the present invention, the solidifying agent comprises shells and peat (Canadian moss peat), the shells are calcined at 600°C for 4h, the peat is calcined at 200°C for 2h, and the specific components are shown in Table 1-0 , after passing #10 mesh (2mm) sieve, according to the mass ratio of 0:0, 1:0, 2:1, add in the middle of certain heavy metal composite polluted soil, obtain S1, S2, two kinds of combined curing agents, wherein S0 is without adding shell ash, peat ash and S2 only adds shell ash and does not add peat ash as the comparison of this combination curing agent invention. The mass rat...

Embodiment 2

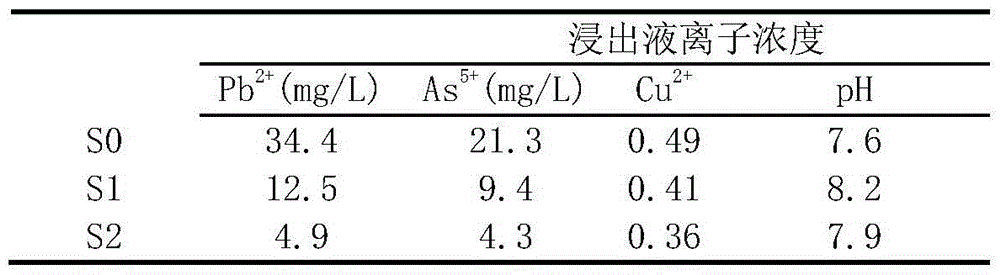

[0030] Embodiment 2: Adopt HJ / T300-2007 method to solidify heavy metal leaching situation, table 2-1 is the leaching concentration of the heavy metal ion of the heavy metal compound polluted soil after curing 14 days in the embodiment 1 of the present invention;

[0031] Table 2-1 TCLP results

[0032]

[0033] During the curing process, the solid waste leaching toxic leaching method—acetic acid buffer solution method (HJ / T300-2007) was used to obtain leachate for the cured body after 14 days of curing.

[0034] It can be seen from the above table 2-1, according to the solid waste leaching toxicity leaching method-acetic acid buffer solution (HJ / T300-2007). The pH value of the leaching solution is reduced due to the addition of peat ash, and the pH changes in the range of 7-10 (S0-S2), which belongs to an alkaline environment and is conducive to the solidification of heavy metals. It is also known that the soil sample S2 heavy metal Pb 2+ 、As 5+ and Cu 2+ The leaching c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com