Anti-reflection permeability-improving glass and preparing method thereof

An anti-reflection and glass technology, applied in the direction of coating, etc., can solve the problems of low glass clarity, no anti-reflection, user interference, etc., and achieve the effect of reducing direct reflection imaging and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

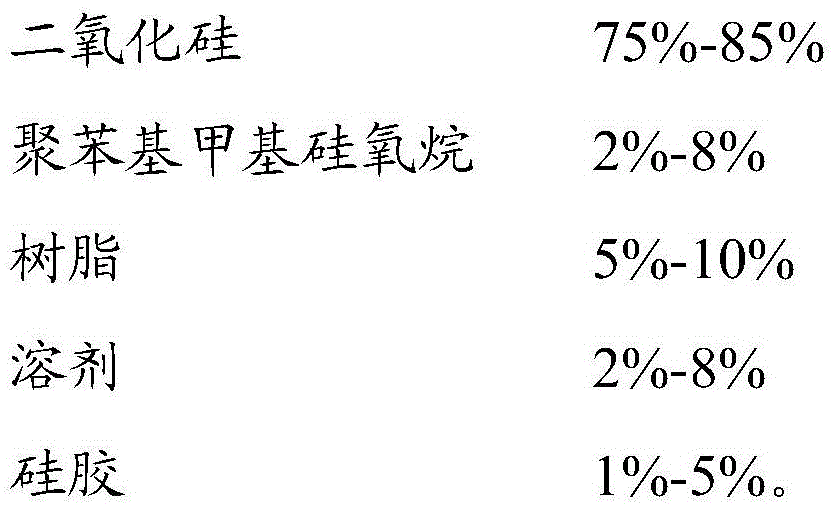

preparation example Construction

[0031] A preparation method of anti-reflection and anti-reflection glass, comprising the following steps:

[0032] 1. Anti-reflection processing.

[0033] A glass substrate is taken, and an anti-reflection film is formed on one side of the glass substrate by magnetron sputtering.

[0034] It can be understood that the anti-reflection film can be prepared on the air side of the glass substrate (that is, the side of the glass facing the air during the glass production process), and can also be prepared on the tin surface of the glass substrate (that is, the glass is stained during the glass production process). However, preparing an anti-reflection film on the air side and an anti-glare film on the tin side can make the obtained anti-reflection film clean and bright, and use the anti-glare film to cover the small defects that may exist on the tin surface .

[0035] Moreover, the anti-reflection film can be prepared by conventional magnetron sputtering method, but the anti-refl...

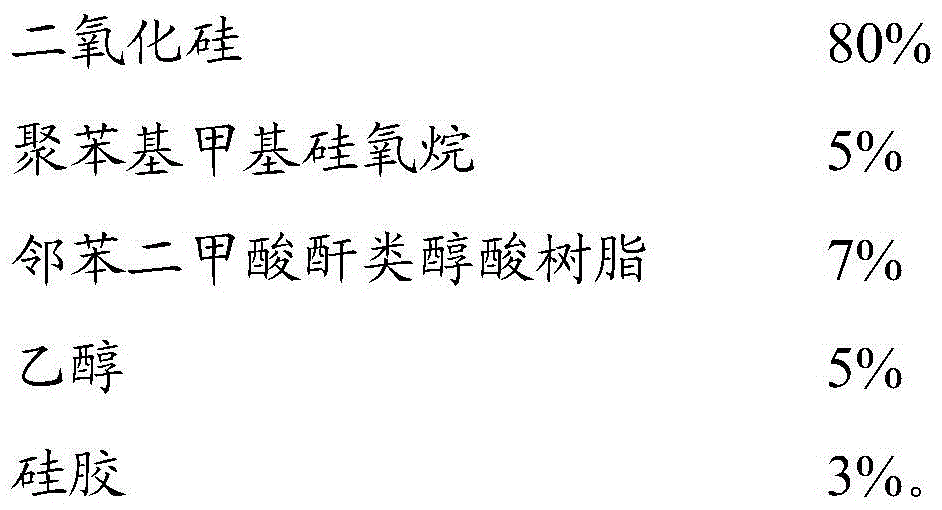

Embodiment 1

[0040] An anti-reflection and anti-reflection glass, prepared by the following method:

[0041] 1. Anti-reflection processing.

[0042] Take the original white glass substrate of the float process, and form an anti-reflection film on the air surface of the glass substrate by magnetron sputtering.

[0043] The technological condition of above-mentioned magnetron sputtering method is: vacuum degree is 2 * 10 -5 torr-5×10 -5 torr, using RF power supply, the frequency of the RF power supply is 13.65MHZ, the power range is 2000W-3000W, the sputtering pressure is 0.3Pa-0.4Pa, the target base distance is 80mm, the Ar gas flow rate is 170sccm, and the substrate temperature is 130 ℃, the reaction gas is: a mixed gas of nitrogen, oxygen, methane, acetylene, and carbon monoxide, and the sputtering target materials are: nickel and silver.

[0044] 2. Anti-glare treatment.

[0045] 1. Polishing.

[0046] The above glass substrate is taken, washed with water and then dried to obtain cl...

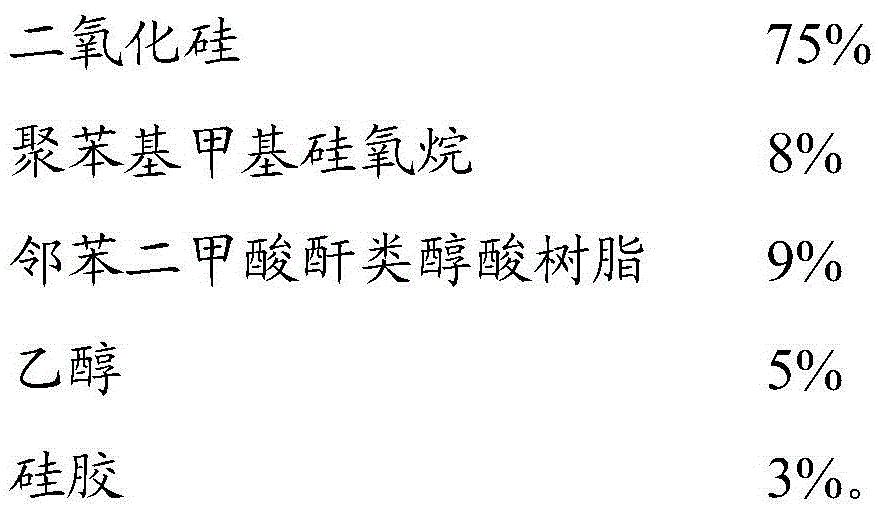

Embodiment 2

[0058] An anti-reflection and anti-reflection glass, prepared by the following method:

[0059] 1. Anti-reflection processing.

[0060] Take the original white glass substrate of the float process, and form an anti-reflection film on the air surface of the glass substrate by magnetron sputtering.

[0061] The technological condition of above-mentioned magnetron sputtering method is: vacuum degree is 2 * 10 -5 torr-5×10 -5 torr, using RF power supply, the frequency of the RF power supply is 10MHZ, the power range is 2000W-3000W, the sputtering pressure is 0.5Pa-0.9Pa, the target base distance is 90mm, the Ar gas flow rate is 160sccm, and the substrate temperature is 110℃ , the reaction gases are: nitrogen, oxygen, methane, acetylene, and carbon monoxide, and the sputtering targets are: nickel and titanium.

[0062] The sputtering gas pressure of 0.5Pa-0.9Pa is slower than that of the sputtering gas pressure of 0.3Pa-0.4Pa in Example 1.

[0063] 2. Anti-glare treatment.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com