Alkali activated concrete and its preparation method

An alkali excitation and concrete technology, applied in the field of concrete, can solve problems such as occupying large land, environmental pollution, and affecting the economic benefits of extracting alumina from high-alumina fly ash, and achieve excellent work performance and strength performance, which is conducive to resource utilization , Excellent resistance to sulfate attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of alkali activated concrete:

[0035] (1) Preparation of calcium-silicon slag micropowder: After drying the original calcium-silicon slag, grind it in a ball mill to 26.0% to 28.0% of the sieve of 80 μm, and prepare the calcium-silicon slag micropowder;

[0036] (2) Preparation of alkali-activated gelling material powder: use silicon-calcium slag micro-powder with a specific surface area of 400m 2 / kg of mineral powder, specific surface area 600m 2 / kg ultra-fine ore powder is used as a raw material, and the silicon-calcium slag micro-powder, ore powder, and ultra-fine ore powder are mixed evenly in a certain proportion to prepare alkali-activated gelling material powder;

[0037] (3) Preparation of alkali-activated concrete: Add alkali-activated cementitious material powder, coarse aggregate, fine aggregate, and water in proportion to the concrete mixer and stir evenly, then add liquid water glass of a ce...

Embodiment 2

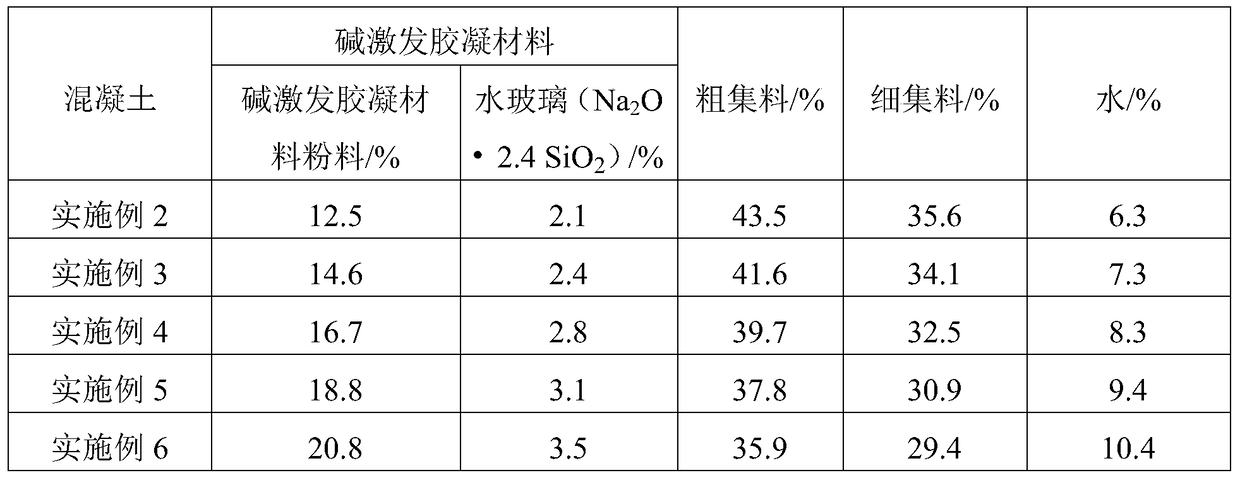

[0039] Fixed silicon-calcium slag micropowder: mineral powder: the mass ratio of superfine mineral powder is 70:15:15, select water glass (Na 2 O nSiO 2 ) modulus of 2.40, repeat the method in Example 1 to prepare alkali-activated concrete. The mass ratios of alkali-activated gelling material powder, coarse aggregate, fine aggregate, water, and water glass are shown in Table 1.

[0040]Refer to GB / T 50080-2002 "Standard for Test Methods of Performance of Ordinary Concrete Mixtures" to conduct the slump performance test of the prepared alkali-activated concrete. The test results are shown in Table 2.

[0041] According to GB / T 50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete", the compressive strength test of the prepared alkali-activated concrete samples was carried out. The test results are shown in Table 2.

[0042] Referring to GB / T 50082-2009 "Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete", the...

Embodiment 3

[0045] Fixed silicon-calcium slag micropowder: mineral powder: the mass ratio of superfine mineral powder is 70:15:15, select water glass (Na 2 O nSiO 2 ) modulus of 2.40, repeat Example 2 to carry out the alkali-stimulated concrete preparation, slump test, compressive strength test, freeze-thaw cycle performance test and sulfate erosion resistance test of this embodiment. The mass ratios of alkali-activated gelling material powder, coarse aggregate, fine aggregate, water, and water glass are shown in Table 1. The results of slump performance and compressive strength performance are shown in Table 2. The results of freeze-thaw cycle performance are shown in Table 3. The results of sulfate attack resistance are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com