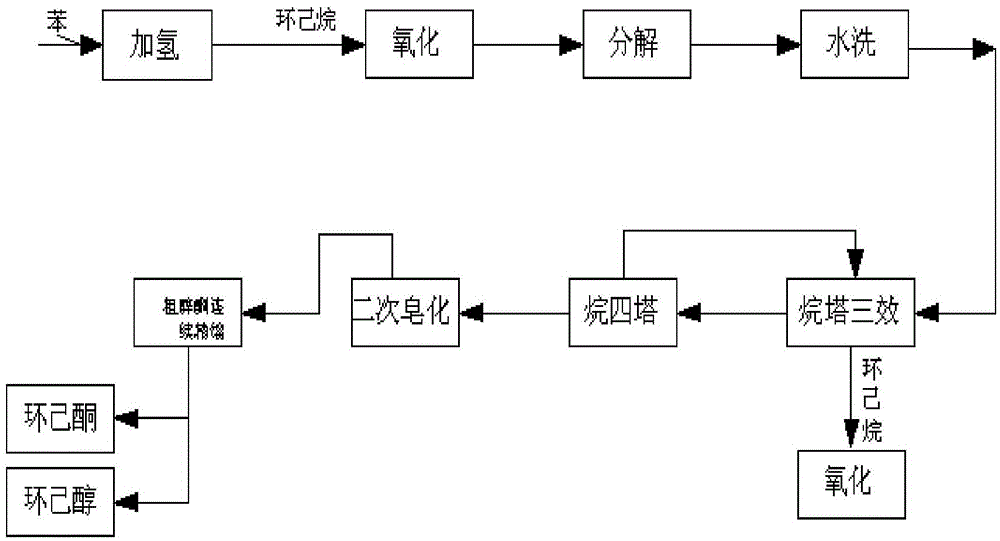

Method for preparing cyclohexanone with cyclohexane liquid-phase oxidation process

A liquid phase oxidation method, cyclohexane technology, applied in the separation/purification of carbonyl compounds, organic chemistry and other directions, can solve the problems affecting the quality of the product cyclohexanone, achieve better separation effect, less fixed investment and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

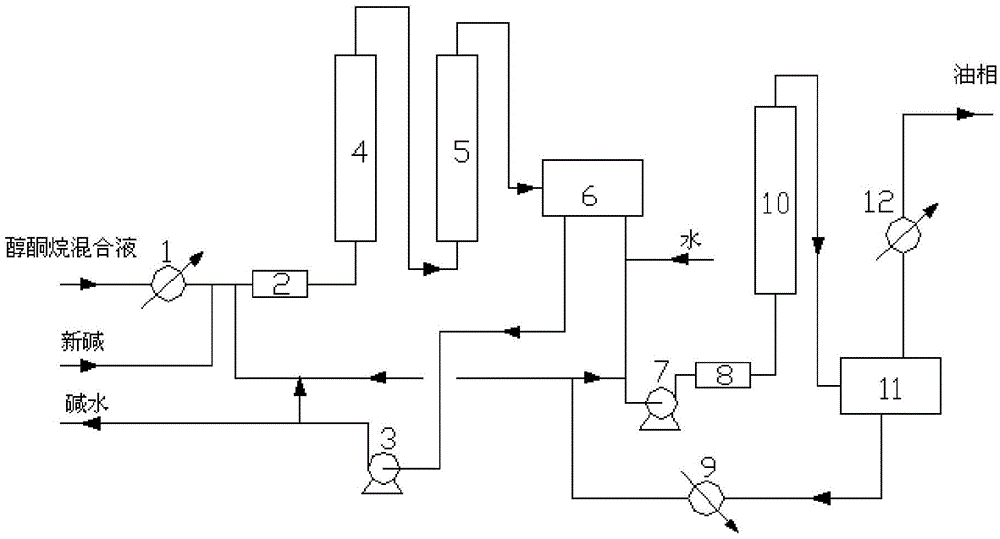

[0030] The alcohol and ketone mixed solution containing alkane 50wt% that the three-effect alkane tower rectification operation obtains is in 40m 3 / h enters the feed heater 1 for heating, and after heating to 94.5°C, the flow rate is 0.3m 3 / h fresh sodium hydroxide solution enters the first static mixer 2 together, and then enters the first saponification tower 4 (Φ800×15000, Pall ring packing, operating temperature is 91.0°C) from the bottom, and the second saponification tower 5 (Φ800×15000, Pall ring packing, operating temperature is 90.0°C), relying on pressure difference to overflow from the top of the second saponification tower 5 and enter the first separator 6 (horizontal tank separator, Φ3200×7000, V= 65.5m 3 ). The first separator 6 (Φ3200×7000, V=65.5m 3 ) bottom lye, through circulation pump 3, most (8m 3 / h) circulating to the first static mixer 2, a small portion (1.2m 3 / h) to control the first separator 6 (Φ3200×7000, V=65.5m 3 ) Alkaline oil interface,...

Embodiment 2

[0032] The alcohol and ketone mixed solution containing alkane 55wt% that the three-effect alkane tower rectification operation obtains is in 42m 3 / h into the feed heater 1 for heating, after heating to 93.5°C, the flow rate is 0.28m 3 / h of fresh sodium hydroxide solution enters the first static mixer 2 together, and then enters the first saponification tower 4 (Φ800×15000, Pall ring packing, operating temperature is 93.8 ° C) from the bottom, and the second saponification tower 5 (Φ800×15000, Pall ring packing, operating temperature is 93°C), relying on pressure difference to overflow from the top of the second saponification tower 5 and enter the first separator 6 (Φ3200×7000, V=65.5m 3 ). The first separator 6 (Φ3200×7000, V=65.5m 3 ) bottom lye, through circulation pump 3, most (8.2m 3 / h) circulating to the first static mixer 2, a small portion (1.0m 3 / h) to control the first separator 6 (Φ3200×7000, V=65.5m 3 ) Alkaline oil interface, sent to the previous process....

Embodiment 3

[0034] The alcohol and ketone mixed solution containing alkane 53wt% that the three-effect alkane tower rectification operation obtains is in 39m 3 / h enters the feed heater 1 for heating, and after heating to 93.0°C, the flow rate is 0.25m 3 / h of fresh sodium hydroxide solution enters the first static mixer 2 together, and then enters the first saponification tower 4 (Φ800×15000, Pall ring packing, operating temperature is 93.4 ° C) from the bottom, and the second saponification tower 5 (Φ800×15000, Pall ring packing, operating temperature is 92.5°C), relying on pressure difference to overflow from the top of the second saponification tower 5 and enter the first separator 6 (Φ3200×7000, V=65.5m 3 ). The first separator 6 (Φ3200×7000, V=65.5m 3 ) bottom lye, through circulation pump 3, most (7.9m 3 / h) circulating to the first static mixer 2, a small portion (0.9m 3 / h) to control the first separator 6 (Φ3200×7000, V=65.5m 3 ) Alkaline oil interface, sent to the previous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com