Preparation method for hydroxaminopolyether

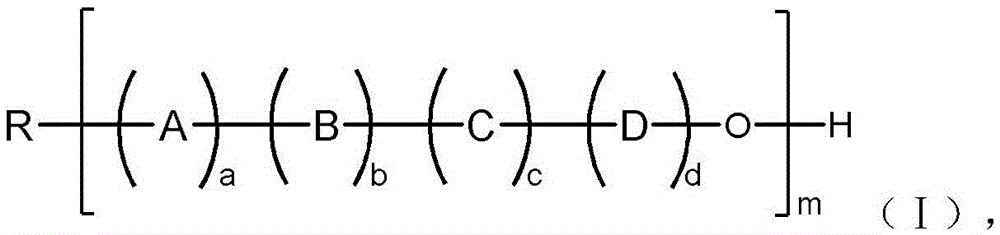

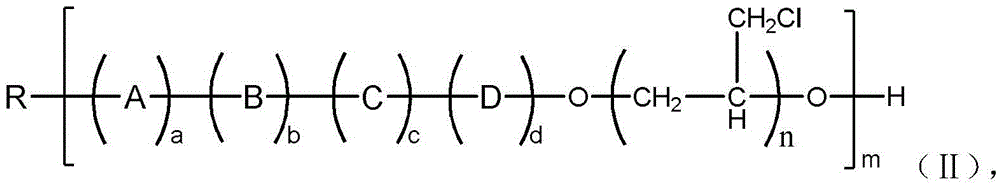

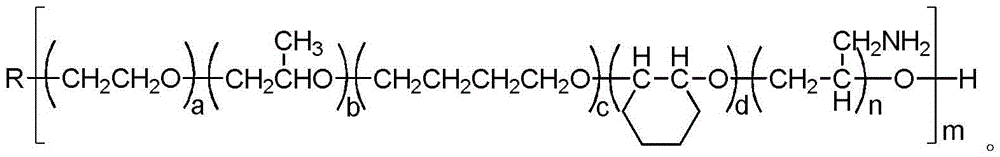

A technology of hydroxylamino polyether and chlorinated polyether, which is applied in the field of preparation of large molecular weight hydroxylamino polyether, can solve the problems of low catalyst efficiency, many reaction by-products, strict equipment requirements, etc., so as to overcome the low catalyst efficiency and high Conversion rate, the effect of efficient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Polyether polyol, the synthesis initiator is methanol, the polymerization monomer is ethylene oxide, the degree of polymerization is 11, and the number average molecular weight is 516g / mol. The number of terminal hydroxyl groups of polyether polyol / epichlorohydrin molar ratio is 1:1, the concentration of catalyst DMC is 40ppm, and the cocatalyst Sc(CF 3 SO 3 ) 3 The addition amount is 0.2% of the polyether polyol substance amount. Weigh polyether polyol 1mol (516g), epichlorohydrin 1mol (92.5g), 24mg catalyst DMC, 0.98g promoter Sc (CF 3 SO 3 ) 3. Add the above-mentioned substances into a closed reaction kettle, raise the temperature to 110°C, keep the temperature for 1 hour, remove volatile substances under reduced pressure, and remove insoluble substances by filtration to obtain a chlorinated polyether intermediate.

[0031] The molar ratio of the number of terminal hydroxyl groups of polyether polyol to amination reagent is 1:1, and the amount of reaction solve...

Embodiment 2

[0033] Polyether polyol, the synthetic initiator is methallyl alcohol, the polymerized monomers are ethylene oxide and propylene oxide, the degree of polymerization of ethylene oxide is 10, the degree of polymerization of propylene oxide is 5, the number average The molecular weight is 802.6 g / mol. The number of terminal hydroxyl groups of polyether polyols / epichlorohydrin molar ratio is 1:1, the concentration of catalyst DMC is 40ppm, and the cocatalyst AlCl 3 The addition amount is 0.4% of the polyether polyol substance amount. Weigh 1mol (802.6g) of polyether polyol, 1mol (92.5g) of epichlorohydrin, 36mg catalyst DMC, 0.53g cocatalyst AlCl 3 . Add the above-mentioned substances into a closed reaction kettle, raise the temperature to 110°C, keep the temperature for 1.5 hours, remove volatile substances under reduced pressure, and remove insoluble substances by filtration to obtain a chlorinated polyether intermediate.

[0034] The molar ratio of the number of terminal hyd...

Embodiment 3

[0036] Polyether polyol, the synthetic initiator is 1-stearyl alcohol, the polymerized monomers are propylene oxide and tetrahydrofuran, the degree of polymerization of propylene oxide is 5, the degree of polymerization of tetrahydrofuran is 20, and the number average molecular weight is 2003.2g / mol . The number of terminal hydroxyl groups of polyether polyols / epichlorohydrin molar ratio is 1:2, the concentration of catalyst DMC is 50ppm, and the cocatalyst Sc(CF 3 SO 3 ) 3 The addition amount is 0.3% of the polyether polyol substance amount. Weigh polyether polyol 1mol (2003.2g), epichlorohydrin 2mol (185g), 0.11g catalyst DMC, 1.48g promoter Sc (CF 3 SO 3 ) 3 . Add the above-mentioned substances into a closed reaction kettle, raise the temperature to 130°C, keep the temperature for 4 hours, remove volatile substances under reduced pressure, and remove insoluble substances by filtration to obtain a chlorinated polyether intermediate.

[0037] The number of terminal hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com