Iron-based coating material for heat insulating protection and coating preparation method thereof

A coating, iron-based technology, applied in the field of thermal insulation protective coating materials and their preparation, can solve the problem of no iron-based amorphous/nanocrystalline coating, etc., and achieve good wear resistance, cost reduction, and good thermal expansion matching. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

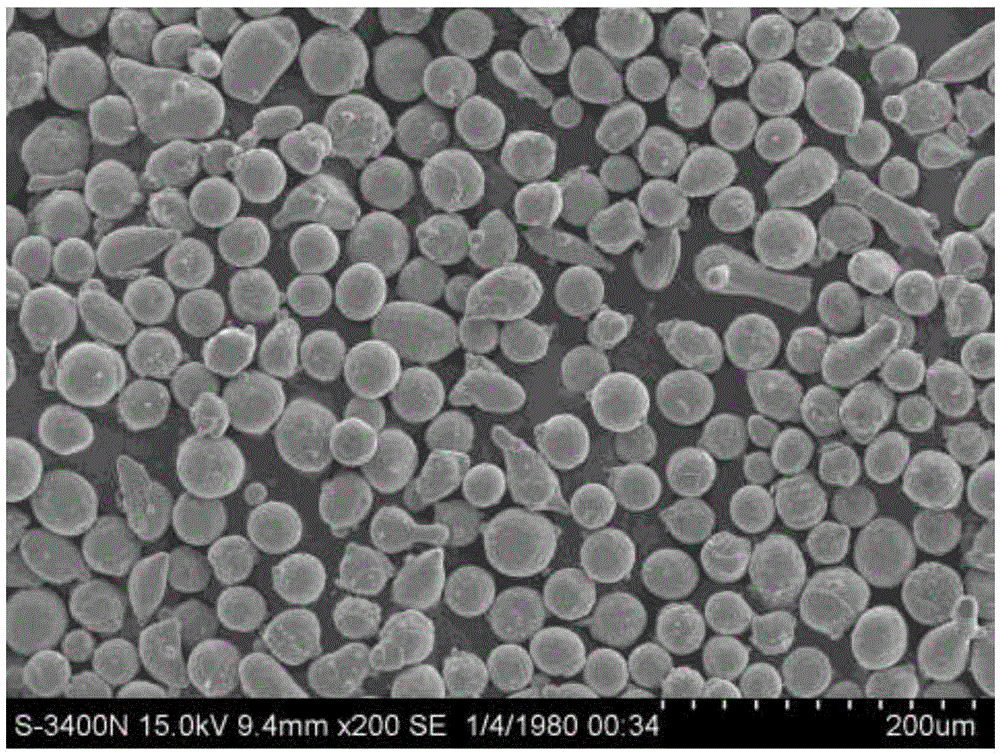

Embodiment 1

[0042] The mass percentages of raw materials required for preparing the iron-based alloy powder are as follows: ferroboron: 27%; ferroniobium: 16%; ferrosilicon: 1.5%; pure chromium: 10%; and the balance is pure iron. Preparation of iron-based thermal insulation coating, spraying process parameters: kerosene flow rate: 6.2GPH, oxygen flow rate: 2000SCFH, powder feeding rate: 5r / min, spraying distance: 380mm, powder feeding gas flow rate: 25SCFH.

Embodiment 2

[0044] The mass percentages of the raw materials required to prepare the iron-based alloy powder are as follows: ferroboron: 22%; ferroniobium: 13.5%; ferrosilicon: 3.0%; pure chromium: 12.5%; the balance is pure iron. Preparation of iron-based thermal insulation coating, spraying process parameters: kerosene flow rate: 6.2GPH, oxygen flow rate 2000SCFH, powder feeding rate: 5r / min, spraying distance: 380mm, powder feeding gas flow rate: 25SCFH.

Embodiment 3

[0046] The mass percentages of the raw materials required to prepare the iron-based alloy powder are as follows: ferroboron: 22%; ferroniobium: 13.5%; ferrosilicon: 3.0%; pure chromium: 12.5%; the balance is pure iron. Preparation of iron-based thermal insulation coating, spraying process parameters: kerosene flow: 5.6GPH, oxygen flow: 1800SCFH, powder feeding rate: 4.5r / min, spraying distance: 360mm, powder feeding gas flow: 20SCFH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com