Preparation method of ZnO transparent conductive film

A transparent conductive thin film and thin film technology, applied in the direction of solid-state chemical plating, metal material coating process, coating, etc., can solve the problems of high preparation cost, unfriendly environment, limited use, etc., and achieve simple operation and simple regulation , Regulate the practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of the ZnO transparent conductive film provided in this embodiment comprises the following preparation steps:

[0021] a), with Zn(Ac) 2 2H 2 O, Al(NO 3 ) 3 9H2O, FeCl 3 ·6H 2 O is a raw material, ethylene glycol methyl ether is a solvent, and ethanolamine is a stabilizer, which is configured into a sol in a certain proportion;

[0022] b), cleaning the glass substrate;

[0023] c) Spin-coat the sol obtained in step a) on the cleaned glass substrate in step b) to form a film; place the coated glass substrate in an oven at 150°C to 250°C for heat treatment for 9 minutes to After 11 minutes, take it out, cool it down to room temperature naturally, and then repeat the spin-coating sol several times to form a film;

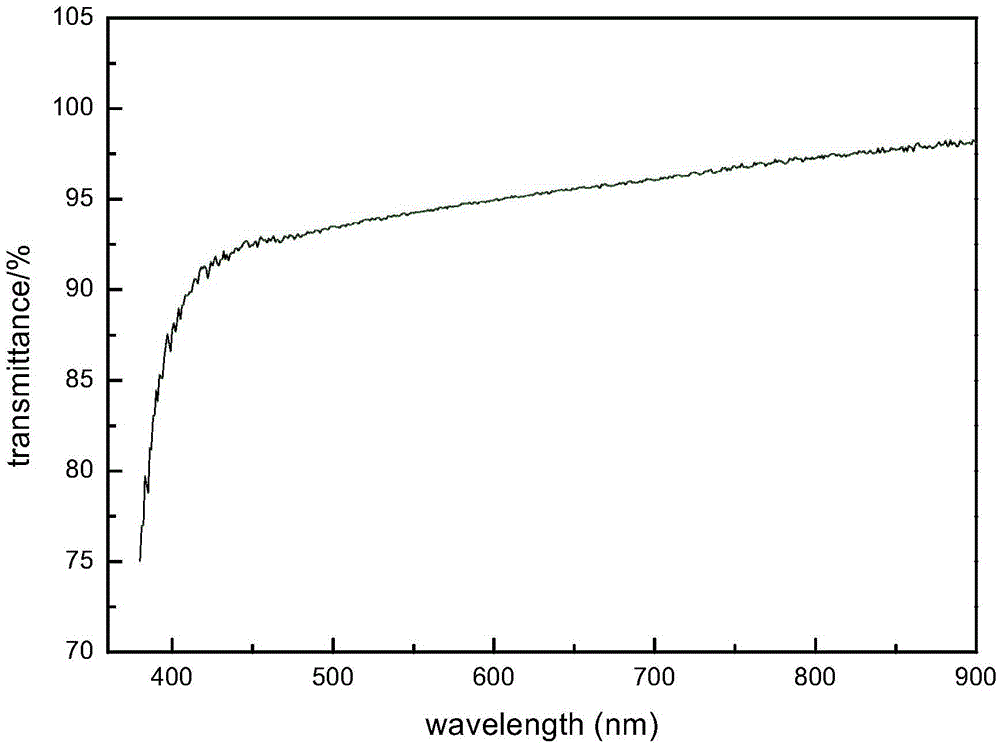

[0024] d) heat-treating the thin film prepared in step c) in the air environment, then a ZnO transparent conductive thin film with high transmittance in the visible light band can be obtained.

[0025] In the above-mentioned prepa...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is:

[0034] In this embodiment, in step a), with Zn(Ac) 2 2H 2 O, Al(NO 3 ) 3 9H2O, FeCl 3 ·6H 2 O and CoCl2·6H2O are raw materials, among which, the concentration of Co ions is 0.005mol / L~0.035mol / L, and the total concentration of Fe ions and Co ions is kept in the range of 0.01~0.07mol / L, and other preparation conditions remain unchanged .

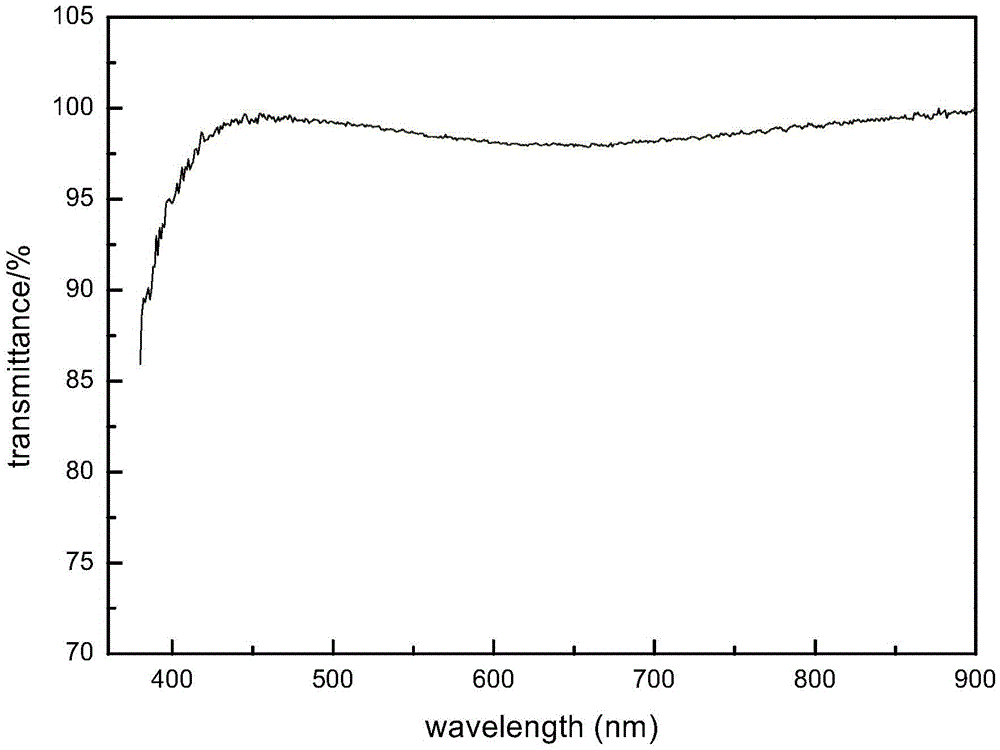

[0035] refer to image 3 As shown, the ZnO transparent conductive film has a transmittance of over 90% in the visible light band.

Embodiment 3

[0037] The difference between this embodiment and embodiment two is:

[0038] In step c), the spin coating is repeated seven times on the glass substrate to obtain a thicker ZnO transparent conductive film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com