A method for in-situ addition of nanometals to prepare continuous SIO2/nanometal airgel fibers with catalytic properties

An aerogel fiber, nano-metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical characteristics of fibers, etc., can solve the problem of inconvenient use, low catalyst utilization, and contact area. drop etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

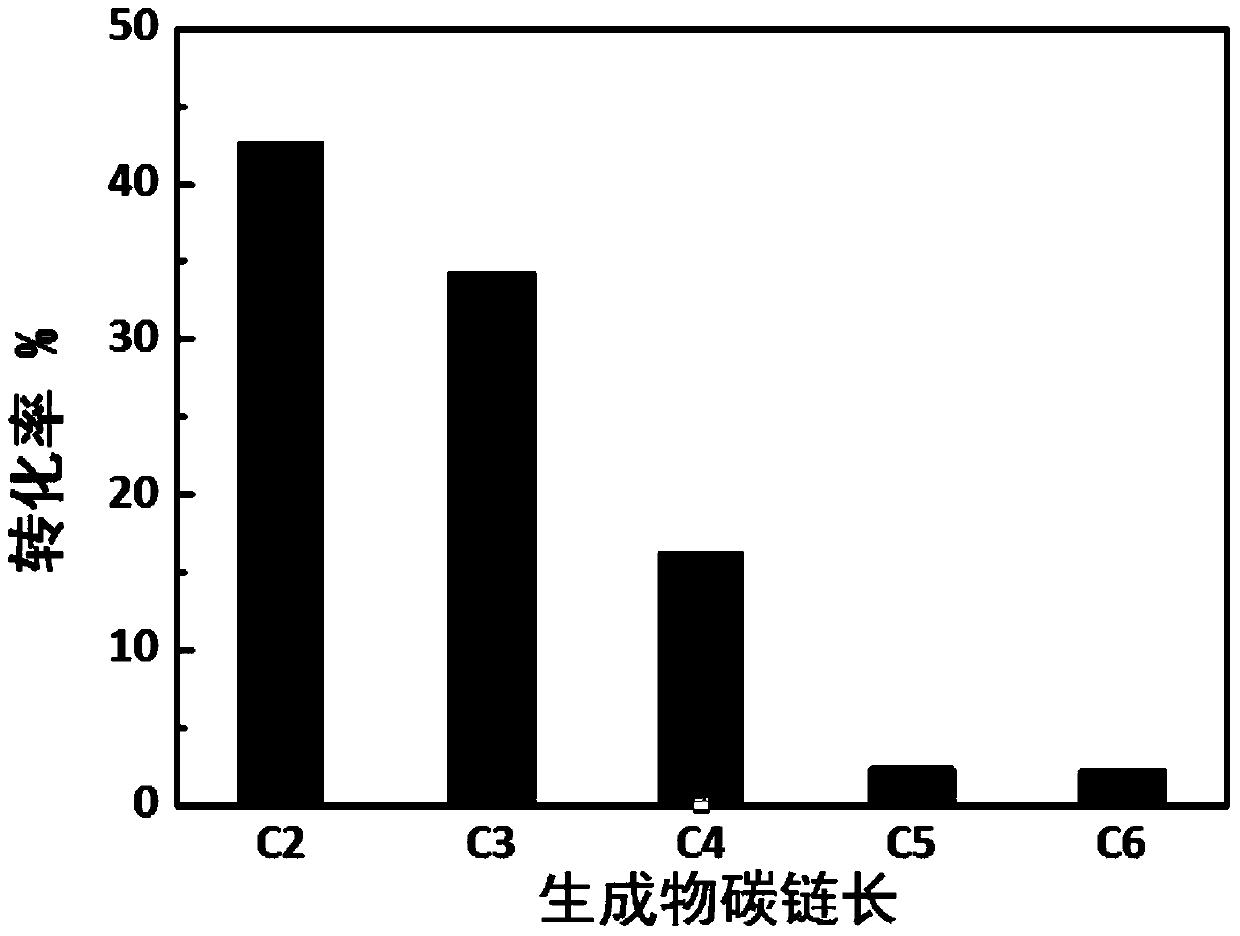

Embodiment 1

[0031] Soda water glass with a modulus of 2 and 50 Baume degrees mixed with 0.5wt% catalyst nano-Pt was used as the spinning stock solution, and 0.8 mol / L dilute sulfuric acid solution was used as the coagulation bath to carry out reactive wet spinning. The orthosilicic acid / silicate fiber containing nano-Pt formed in the coagulation bath was wound at a winding speed of 0.1 m / s. The wound fiber was immersed in 0.005mol / L dilute sulfuric acid for 10 days for aging to realize the transformation from orthosilicic acid / silicate fiber to SiO 2 The fibers are transformed, and a large number of holes are formed at the same time. After aging, the fibers were washed with deionized water until neutral. Use deionized water to replace the solvent in the fiber, and freeze-dry to obtain SiO 2 / Nano Pt airgel fibers. The spinning process is very smooth and continuous. Prepared SiO 2 / Nano Pt airgel fiber specific surface area is 543.5m 2 / g, the most probable pore diameter is 16nm. SiO ...

Embodiment 2

[0033] Potassium water glass with a modulus of 3 and 35 degrees Baume mixed with 1 wt% catalyst nano-Pt was used as spinning stock solution, and 0.2 mol / L dilute sulfuric acid solution was used as coagulation bath to carry out reactive wet spinning. The orthosilicic acid / silicate fiber containing nano-Pt formed in the coagulation bath was wound at a winding speed of 0.5 m / s. The wound fiber was immersed in 0.005mol / L dilute sulfuric acid for 10 days for aging, so as to realize the transformation from orthosilicic acid / silicate fiber to SiO 2 The fibers are transformed, and a large number of holes are formed at the same time. After aging, the fibers were washed with deionized water until neutral. Use deionized water to replace the solvent in the fiber, and freeze-dry to obtain SiO 2 / Nano Pt airgel fibers. Occasionally, there is a phenomenon of broken filaments during the spinning process. Prepared SiO 2 / Nano Pt airgel fiber specific surface area is 452.3m 2 / g, the most...

Embodiment 3

[0035] Potassium water glass with a modulus of 3 and 35 degrees Baume mixed with 0.5wt% catalyst nano-Pd was used as spinning stock solution, and 0.8 mol / L dilute sulfuric acid solution was used as coagulation bath to carry out reactive wet spinning. The orthosilicic acid / silicate fiber containing nano-Pd formed in the coagulation bath was wound at a winding speed of 1 m / s. The wound fiber was immersed in 0.1mol / L dilute sulfuric acid for 5 days for aging, and the transformation from orthosilicic acid / silicate fiber to SiO 2 The fibers are transformed, and a large number of holes are formed at the same time. After aging, the fibers were washed with deionized water until neutral. Use deionized water to replace the solvent in the fiber, and freeze-dry to obtain SiO 2 / Nano Pd airgel fibers. Occasionally, there is a phenomenon of broken filaments during the spinning process. Prepared SiO 2 / Nano Pd airgel fiber specific surface area is 423.8m 2 / g, the most probable pore d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com