Electrochemical thin-film condensation sensor

A condensation sensor, electrochemical technology, applied in the field of sensors, can solve the problems of unquantifiable surface condensation, complex structure, complex operation, etc., and achieve the effect of strong practicability, simple structure, and good response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

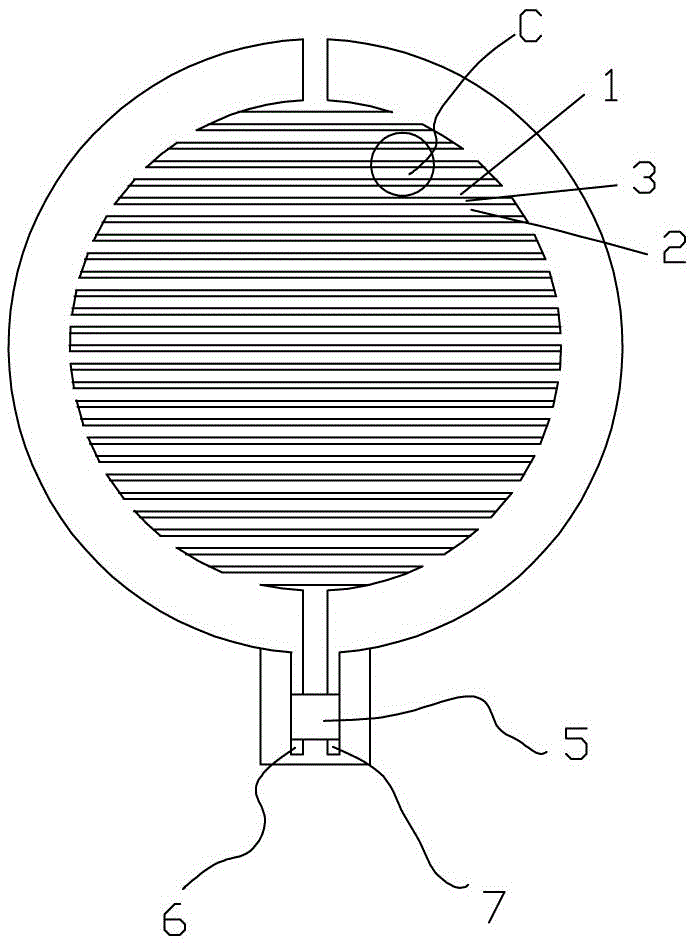

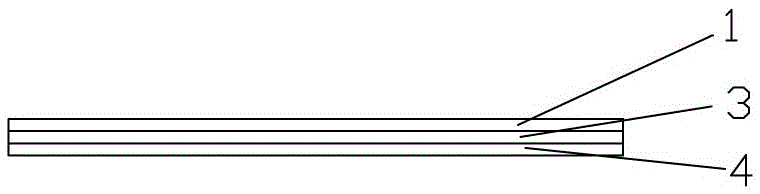

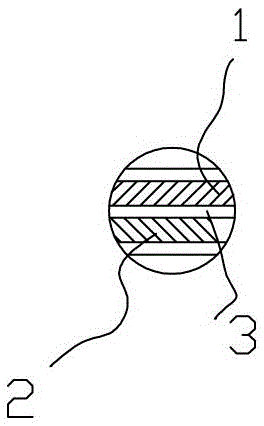

[0031] Such as figure 1 As shown, the present invention has a comb-like structure, and the positive electrode 1 and the negative electrode 2 are arranged alternately in a comb-like shape. The smaller the gap between the positive electrode conductor material and the negative electrode conductor material, the better the sensitivity to condensation, but due to the limitation of material processing technology, combined with image 3 As shown, the distance between the positive electrode 1 and the negative electrode 2 is set at 0.01-1 mm. The positive electrode 1 and the negative electrode 2 are connected to the output positive electrode 6 and the output negative electrode 7 through the amplifier circuit 5 . The positive electrode 1 and the negative electrode 2 are output to the amplifying circuit 5 , and the amplified signal is output by the sensor through the positive ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com