Asynchronous switching three-zone-belt simulation moving bed

A simulated moving bed, asynchronous technology, applied in the field of separation engineering, can solve the problems of increasing the dead volume of the system, large solvent consumption, etc., and achieve the effect of improving utilization rate, product purity or processing capacity, and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

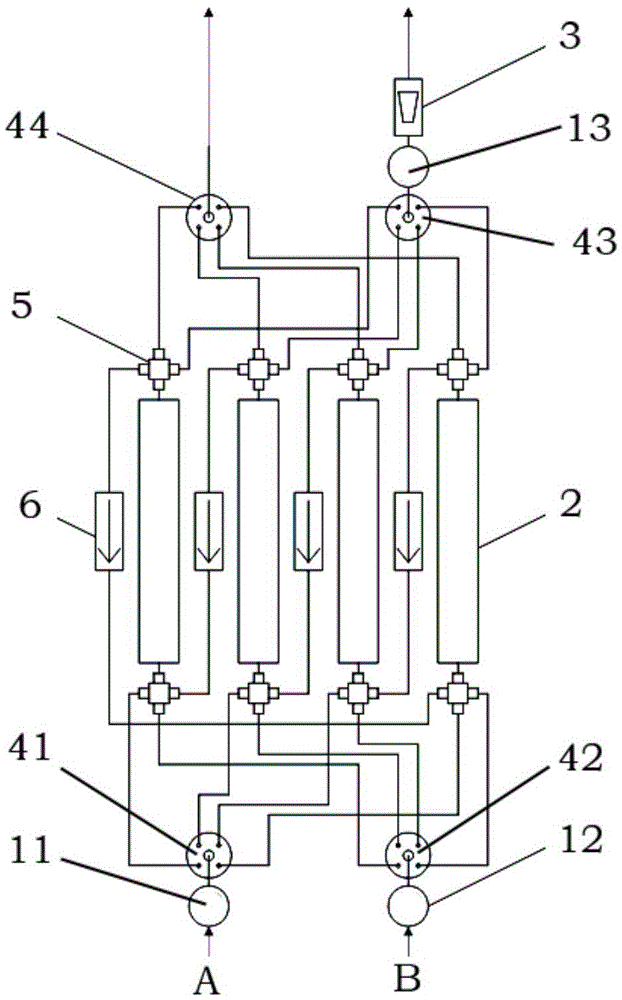

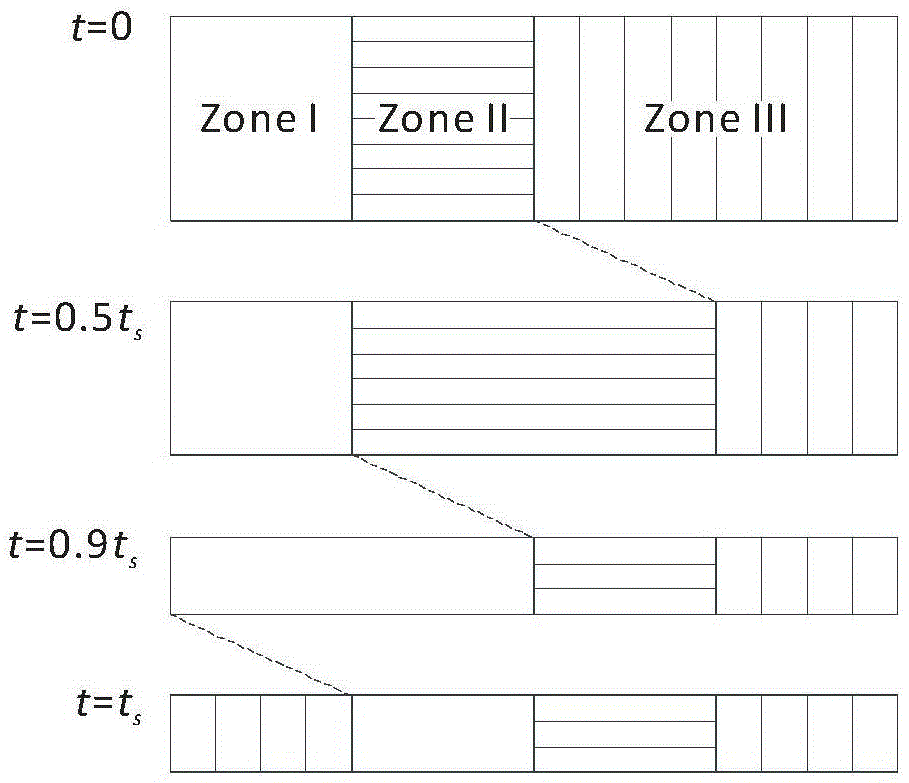

[0023] Example 1. Separation of vanillin and syringaldehyde in a three-zone simulated moving bed with asynchronous switching

[0024] Vanillin (4-hydroxy-3-methoxybenzaldehyde) is an important spice, which is widely used in food, cosmetics, and pharmaceutical production. In the process of hydrolyzing lignin to produce vanillin, the product contains its Structural analog syringaldehyde (4-hydroxy-3,5-dimethoxybenzaldehyde), the two are difficult to separate. The asynchronous switching three-zone simulated moving bed system of the present invention can be used for separation. A 750 μm C18 filler was used as the stationary phase and packed into four preparative columns with an inner diameter of 1 cm and a length of 15 cm. The mobile phase used 33% ethanol aqueous solution. Product analysis adopts C18 filler with a particle size of 5 μm, a 250mm×4.6mm analytical column, and a detection wavelength of 310nm.

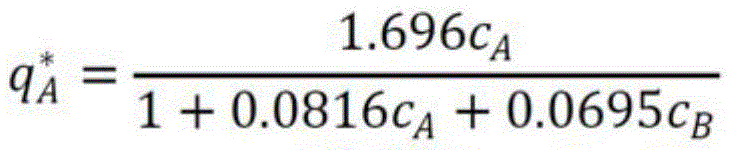

[0025] Firstly, the adsorption isotherms of vanillin and syringaldehyde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com