Method for producing lesinurad intermediate 4-cyclopropyl-1-naphthylamine

A compound and molar technology, applied in the field of medicine, can solve problems such as unsatisfactory safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

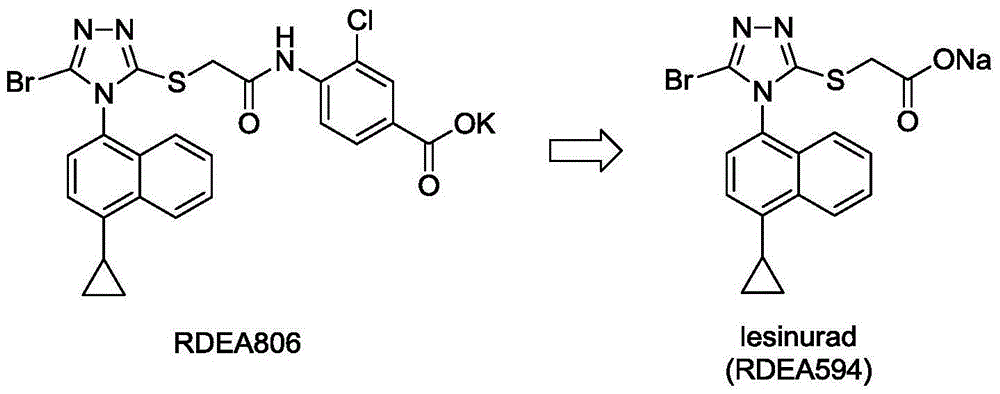

AI Technical Summary

Problems solved by technology

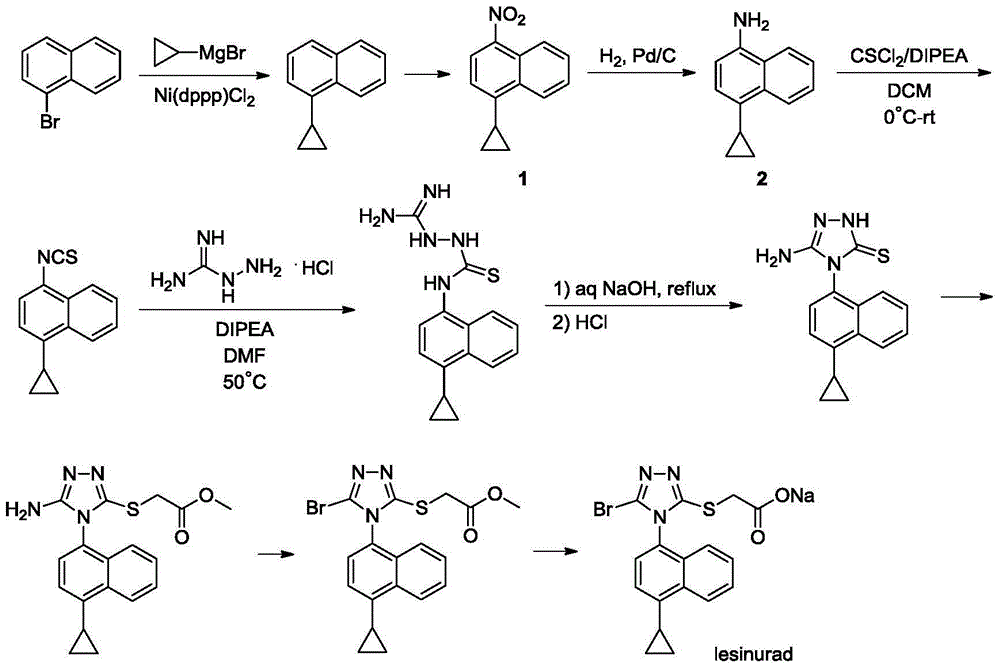

Method used

Image

Examples

Embodiment 1

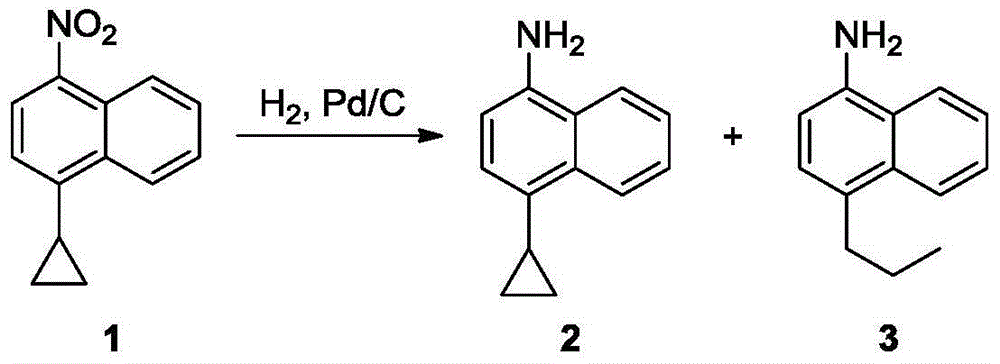

[0014] 21.32g (0.1mol) of 4-cyclopropyl-1-nitronaphthalene 1 was dissolved in 300mL of absolute ethanol, stirred at room temperature, 7.68g of 10% Pd / C was added, and catalytic hydrogenation was carried out overnight at room temperature, TLC showed that the reaction was complete .

[0015] The reaction mixture was suction filtered to remove the catalyst, the filtrate was evaporated on a rotary evaporator to remove the solvent, and the obtained residue was purified by column chromatography to obtain product 2, a light red oily liquid, 13.56 g, with a yield of 74%. 1 HNMR (DMSO-d 6 ,400MHz),δ:8.24(d,1H,J=8.4Hz),8.07(d,1H,J=8.4Hz),7.46-7.50(m,1H),7.37-7.41(m,1H),6.99( d,1H,J=7.6Hz),6.59(d,1H,J=8.0Hz),5.52(bs,2H),2.10-2.15(m,1H),0.89-0.93(m,2H),0.53-0.57 (m,2H).

[0016] go through 1 According to HNMR analysis, the compound 2 prepared above contains a certain amount of by-product 3 (see summary in Table 1).

Embodiment 2

[0018] 21.32g (0.1mol) of 4-cyclopropyl-1-nitronaphthalene 1 was dissolved in 1000mL of absolute ethanol, stirred at room temperature, 7.68g of 10% Pd / C was added, and catalytic hydrogenation was carried out overnight at room temperature, TLC showed that the reaction was complete .

[0019] The reaction mixture was suction filtered to remove the catalyst, the filtrate was evaporated to remove the solvent on a rotary evaporator, and the obtained residue was purified by column chromatography to obtain product 2, a light red oily liquid, 13.38 g, with a yield of 73%.

[0020] go through 1 According to HNMR analysis, the compound 2 prepared above contains a certain amount of by-product 3.

Embodiment 3

[0022] 21.32g (0.1mol) of 4-cyclopropyl-1-nitronaphthalene 1 was dissolved in 200mL of absolute ethanol, stirred at room temperature, 1.07g of 10% Pd / C was added, and catalytic hydrogenation was carried out overnight at room temperature, TLC showed that the reaction was complete .

[0023] The reaction mixture was suction filtered to remove the catalyst, the filtrate was evaporated to remove the solvent on a rotary evaporator, and the obtained residue was purified by column chromatography to obtain product 2, a light red oily liquid, 13.01 g, with a yield of 71%.

[0024] go through 1 According to HNMR analysis, the compound 2 prepared above contains a certain amount of by-product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com