Composite enzyme preparation for beating household paper to promote fiber modification, preparation method and application thereof

A compound enzyme preparation and household paper technology, which is applied in the field of papermaking, can solve the problems of increasing the number of paper machine breakages, prolonging the enzyme reaction time, and affecting the operation of the paper machine, so as to reduce the loss of fine fibers, increase the volume, and increase the tensile force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The applicant also proposed a preparation method of a composite enzyme preparation for promoting fiber modification by beating household paper, which specifically includes the following steps:

[0061] Step (1): pre-treating the raw enzyme preparations neutral pectinase, neutral xylanase and neutral cellulase respectively;

[0062] Step (2): Mix 25%-40% neutral pectinase, 20%-35% neutral xylanase and 15%-40% neutral cellulase in a mixer. ;

[0063] Step (3): Then add an appropriate amount of preservatives and pass through a diatomaceous earth filter to sterilize, and then prepare a composite enzyme preparation for household paper beating to promote fiber modification after measuring the enzyme activity.

[0064] The application of the above-mentioned composite enzyme preparation in the beating of household paper. In the process of pulping the raw fiber of household paper, the composite enzyme preparation is added at a constant speed through a metering pump, and the water-power...

Embodiment 1

[0072] The specific formula of the compound enzyme preparation is as follows, and the content is the weight percentage of the components: neutral pectinase 40%, neutral xylanase 30%, and neutral cellulase 30%. The preparation method is as follows: the raw enzyme preparations are respectively pre-treated, and then mixed uniformly in a mixer according to the proportion, and then an appropriate amount of preservative is added, sterilized by a diatomaceous earth filter, and then the enzyme activity is measured and quantitatively packaged to become a product.

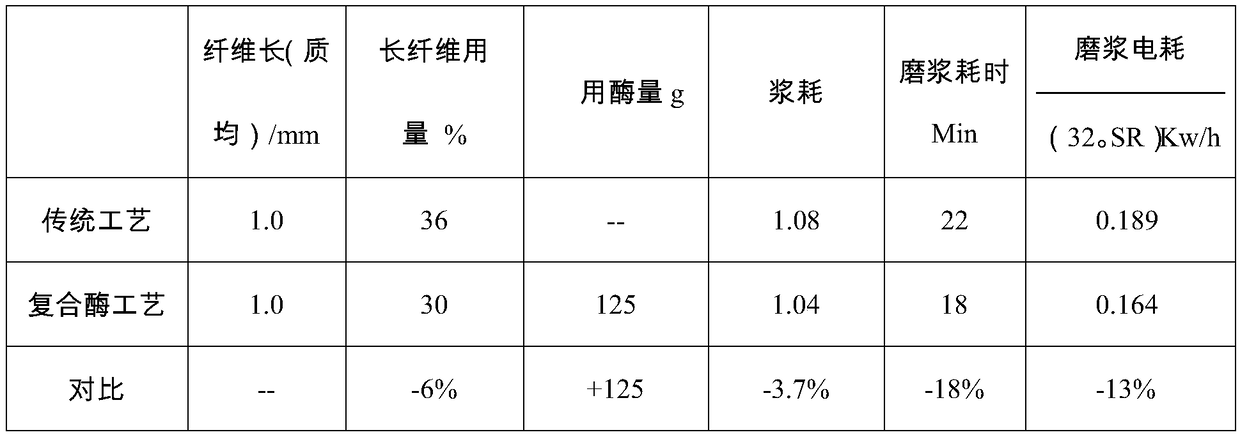

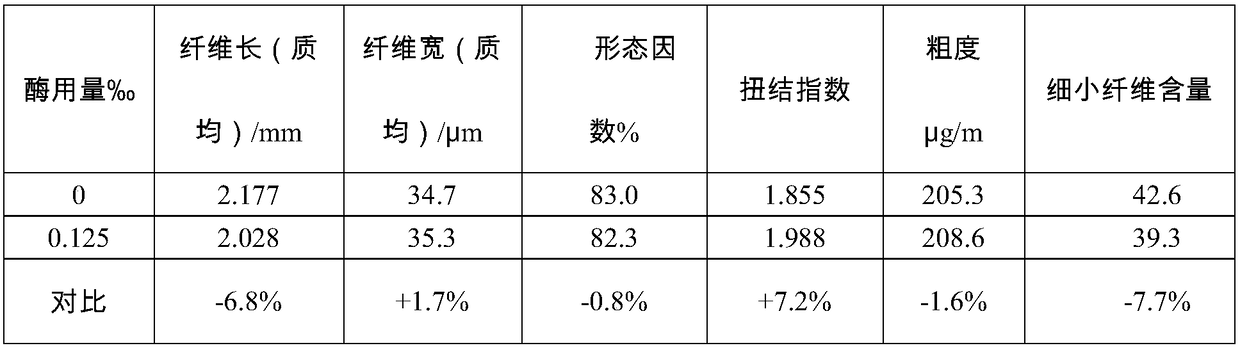

[0073] Production test in a household paper enterprise in Shantou, Guangdong. From December 4th to January 3rd, 2014, a total of 31 days, 50 tons of paper towels were produced per day, 1.2 tons of raw fiber per tank of water conservancy pulper, 150 enzymes added G, the amount of enzyme added is 0.125‰. The production data is shown in the following table 1-3 (based on 1.2 tons of absolute dry pulp).

[0074] Table 1. Comparison o...

Embodiment 2

[0081] The specific formula of the compound enzyme preparation is as follows, and the content is the components in weight percentage: neutral pectinase 35%, neutral xylanase 25%, and neutral cellulase 40%. The preparation method is as follows: the raw enzyme preparations are respectively pre-treated, and then mixed uniformly in a mixer according to the proportion, and then an appropriate amount of preservative is added, sterilized by a diatomaceous earth filter, and then the enzyme activity is measured and quantitatively packaged to become a product.

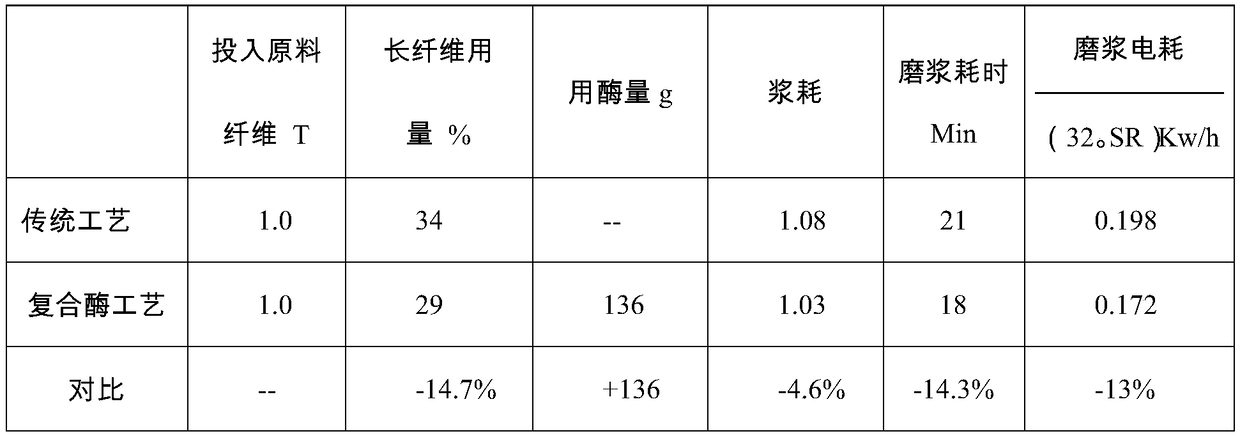

[0082] In a household paper company in Luohe, Henan, from October 8, 2015 to now, 60 tons of tissue paper were produced every day, 2.2 tons of raw material fiber was pulped per tank of water conservancy pulper, 300 grams of enzyme was added, and the amount of enzyme added was 0.136‰. The production data are shown in Tables 4 to 6 below (based on 1 ton of absolute dry pulp).

[0083] Table 4. Comparison of energy consumption during be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com