Formaldehyde-free electroless metal plating compositions and methods

An electrodeless and composite technology, applied in metal material coating process, printed circuit, electrical components, etc., can solve the problems of high operation cost and decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

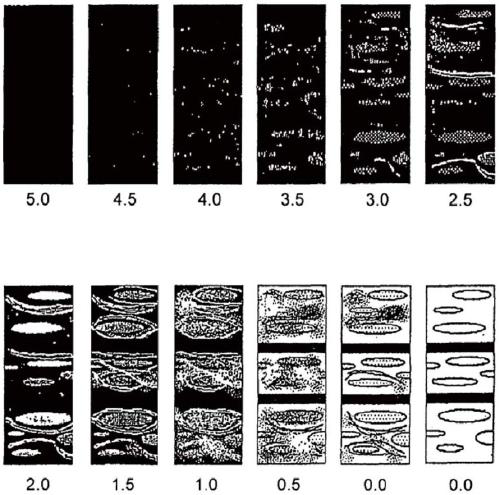

[0089] Glyoxylic acid reduced copper plating compositions were prepared as indicated below. The composition comprises copper ions, glyoxylic acid as a reducing agent, potassium tartrate as a copper complexing agent, potassium hydroxide as a pH regulator, an inhibitor of glyoxylic acid decomposition and 2,2'-linked pyridine. The electroless copper composition is formaldehyde free. It was tested for the quality of its copper deposits and the stability of glyoxylic acid.

[0090] Table 1

[0091]

[0092]

example 2

[0094] The temperature of the composition of Formulation 1 of Table 1 was maintained at 40°C and the pH of the composition was 13 during the electroless copper deposition. Copper was deposited on the substrate for 5 minutes. The substrates used were a non-clad S1141 epoxy / glass laminate measuring 5 cm x 5 cm and a copper clad S1141 ring measuring 2 cm x 3.5 cm obtained from Shengyi Technology Co., Ltd. Oxygen resin / glass multi-layer laminate (six layers). The former is used to measure the deposition rate, and the latter is used to evaluate the backlight performance of the vias. Drill smear and other impurities from the through-holes in each board are then removed in a vertical desmear line process as follows:

[0095] 1. Plate at 75°C with 12.5% CIRCUPOSIT containing TM Solvent expander treatment of MLB Conditioner 211 solution for 5 minutes.

[0096] 2. Each plate was then rinsed with cold water for 3 minutes.

[0097] 3. Plates are subsequently incubated at 80°C with ...

example 3

[0124] Formulations 2 to 4 of Table 1 were treated in the same manner as Example 1. The temperature of the composition was maintained at 40°C and the pH was 13 during the electroless copper deposition. Copper was deposited on the substrate for 5 minutes.

[0125] When nitrilotriacetic acid, Formulation 2 was used as an inhibitor of glyoxylate decomposition, the copper deposit was found to be orange-red, smooth and without observable miss plating. The highest deposition rate achieved was 0.21 microns / 5 minutes. The S1141 copper plated panel had an average backlight value of 4.25. After 6 hours of idling, 41% glyoxylic acid remained and no copper oxide was observed. Therefore, the electroless copper composition is stable.

[0126] When triisopropanolamine, Formulation 3 was used as an inhibitor of glyoxylate decomposition, the copper deposits were found to be red and smooth. Missing plating was not observed. The deposition rate was 0.33 microns / 5 minutes. The S1141 copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com