Method for production of refined dried ramie by microbial blending and degumming

A technology for ramie essence, dried hemp and microorganisms, applied in the field of microorganisms, can solve the problems of inability to completely decompose the compatibility of various components of ramie colloid, and achieve the effects of reducing comprehensive production costs, rapid removal, and low breakage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

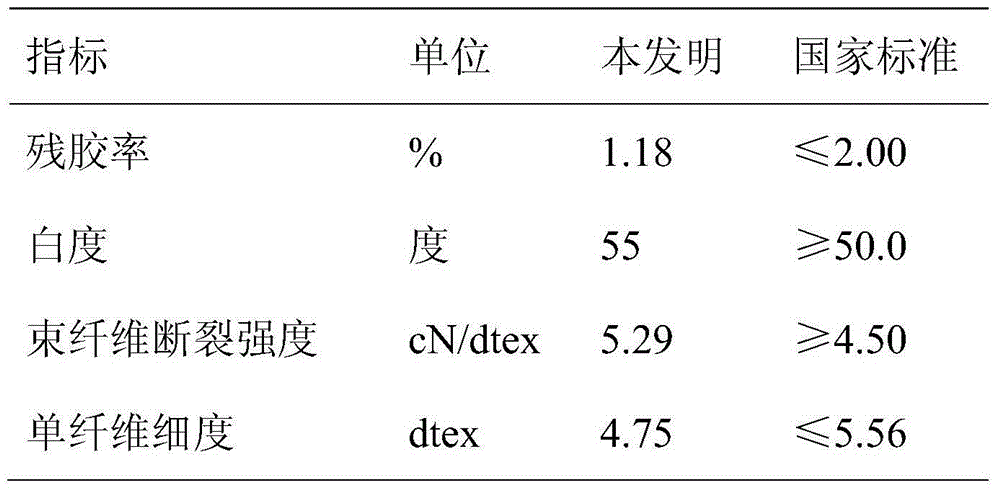

Examples

Embodiment 1

[0041] (1) Preservation, activation and expanded cultivation of Bacillus sp.HG-116

[0042] Strain preservation: Inoculate Bacillus sp.HG-116 strains into 250mL shake flasks filled with 100mL No. 1 medium according to the inoculum amount of 0.5%, and cultivate them at 30°C and 120r / min for 6 hours. The final bacterial solution was stored at -20°C with the glycerol seed preservation method to obtain the HG-116 strain tube;

[0043] Activation: Place the HG-116 strain tube at room temperature for 3 minutes until the bacterial solution melts, inoculate 2.5% of the inoculum into a 1L shaker flask filled with 250mL No. Cultivate under the condition for 1.5h to obtain the activated strain of HG-116.

[0044] Expanded cultivation: The activated strain HG-116 was inoculated into a 50L primary seed tank with 30L No. 3 Cultivate for 7 hours under the condition of air flow per hour. Then inoculate the bacterium solution of the first-level seed tank into the second-level seed tank of 1...

Embodiment 2

[0063] (1) Preservation, activation and expanded cultivation of Bacillus sp.HG-116

[0064] Strain storage: Inoculate Bacillus sp.HG-116 strains into 250mL shake flasks filled with 60mL No. 1 medium according to the inoculum amount of 2.5%, and cultivate them at 40°C and 200r / min for 1.5h. The cultured bacterial solution was stored at -20°C with the glycerol seed preservation method to obtain the HG-116 strain tube;

[0065] Activation: Place the HG-116 strain tube at room temperature for 3 minutes until the bacterial solution melts, inoculate 0.5% of the inoculum into a 1L shaker flask filled with 250mL No. Cultivate under the condition for 6h to obtain the activated strain of HG-116.

[0066] Expanded cultivation: the activated strain HG-116 was inoculated into a 50L primary seed tank with 30L No. 3 / h ventilation conditions for 2h. Then inoculate the bacterium solution of the first-level seed tank into the second-level seed tank of 1t with the specification of 600L No. t...

Embodiment 3

[0085] (1) Preservation, activation and expanded cultivation of Bacillus sp.HG-116

[0086] Strain preservation: Inoculate Bacillus sp.HG-116 strains into 250mL shake flasks filled with 80mL No. 1 medium according to the inoculum amount of 1%, and cultivate them at 36°C and 180r / min for 3 hours. The final bacterial solution was stored at -20°C with the glycerol seed preservation method to obtain the HG-116 strain tube;

[0087] Activation: Place the HG-116 strain tube at room temperature for 3 minutes until the bacterial solution melts, then inoculate 1.2% of the inoculum into a 1L shaker flask containing 250mL No. Cultivate under the condition for 4h to obtain the activated strain of HG-116.

[0088] Expanded cultivation: the activated strain HG-116 was inoculated into a 50L primary seed tank with 30L No. 3 / h ventilation conditions for 4h. Then inoculate the bacterium solution of the first-level seed tank into the second-level seed tank of 1t with the specification of 600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com