Compressed air type motor vehicle exhaust waste heat recycling system and method

A waste heat recovery system, a technology of compressed air, applied in the directions of machines/engines, vehicle components, mechanical equipment, etc., can solve the problems of difficult to achieve long-term battery life, increase engine power, and air consumption large energy, etc., achieve simple and reliable structure, reduce Fuel consumption and emissions, the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention are described in detail as follows:

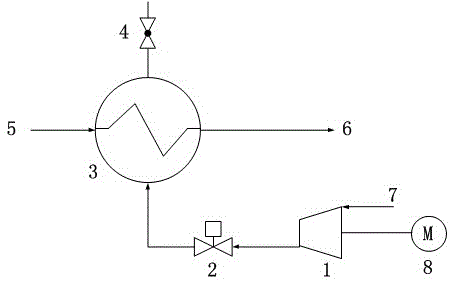

[0022] In this example, see figure 1, a compressed air exhaust heat recovery system for motor vehicles, mainly composed of an air motor 1, a compressed air storage tank 3 and a control system, the compressed air storage tank 3 is provided with a heat exchanger, uses air as the working medium, and uses The high-temperature exhaust gas discharged from the engine is a heat source, and the heat exchanger of the compressed air storage tank 3 includes a high-temperature exhaust gas inlet 5 and a low-temperature exhaust gas outlet 6, forming an independent exhaust gas flow pipeline. The compressed air storage tank 3 is also provided with a compressed air heating area. An independent compressed air pipeline is formed. The high-temperature exhaust gas discharged from the internal combustion engine enters the heat exchanger in the compressed air storage tank 3 from the high-temperature exhaust ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com