Preparing method for in-situ growth of graphene on graphite fibers

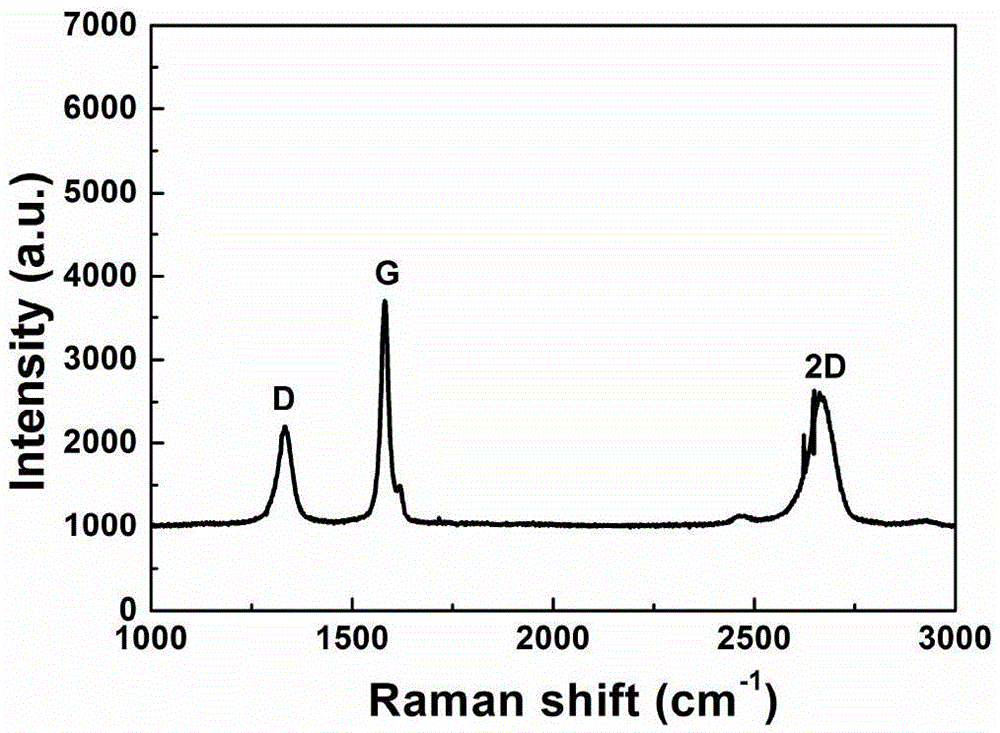

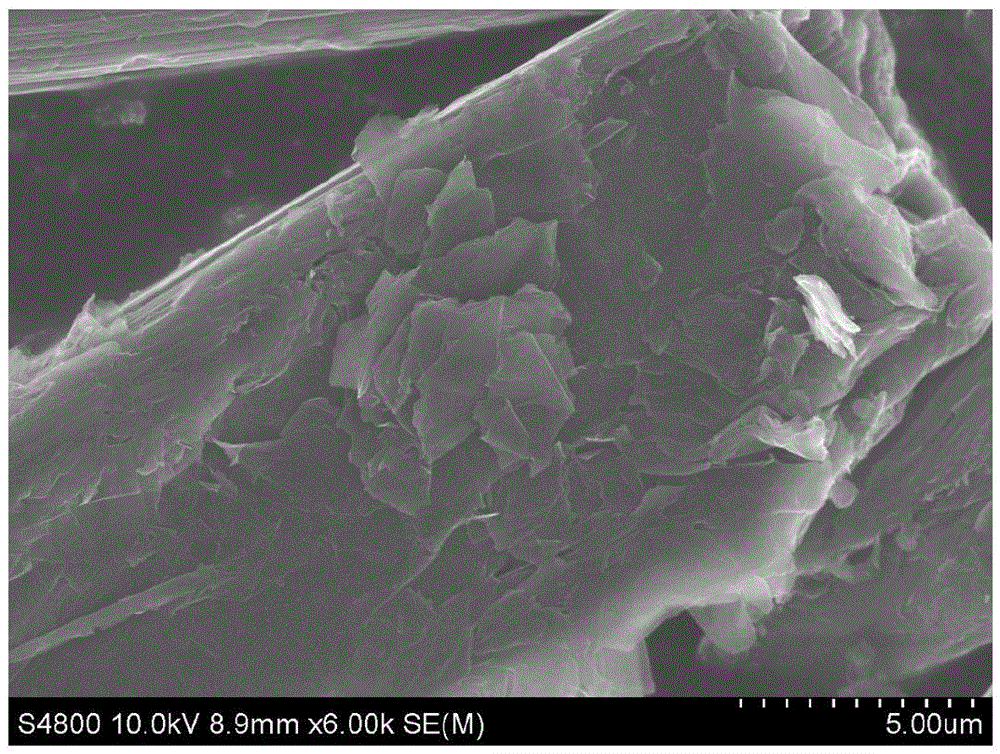

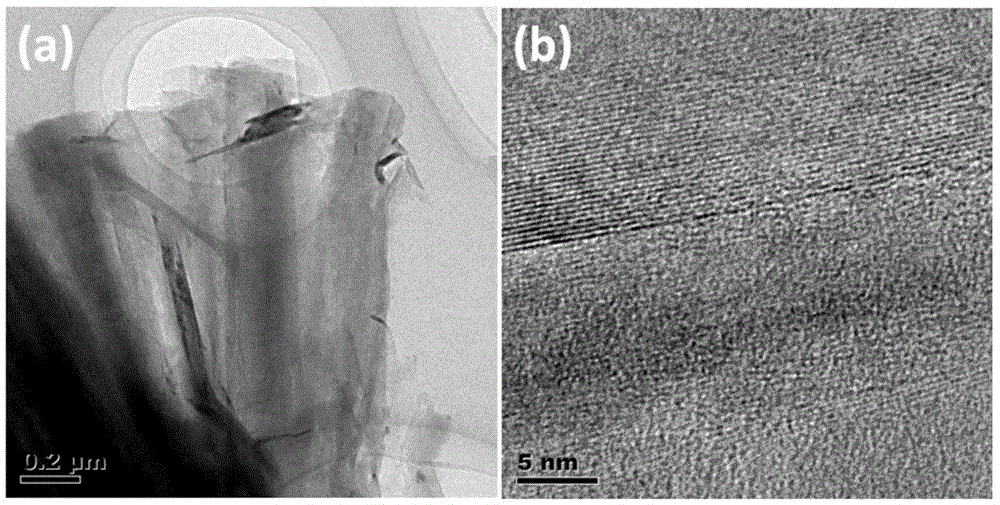

A graphite fiber and in-situ growth technology, which is applied in the field of in-situ growth of graphene on graphite fiber, can solve the problems of irreversible agglomeration and achieve the effect of good conductivity, high purity and few defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Measure 25g each of concentrated sulfuric acid and hydrofluoric acid, pour the concentrated sulfuric acid and hydrofluoric acid into a beaker, mix the concentrated sulfuric acid and hydrofluoric acid evenly, and configure a mixed solvent with a mass ratio of 1:1.

[0029] (2) Weigh 1 g of graphite fiber and disperse the graphite fiber in a mixed solvent of 50 g of concentrated sulfuric acid and hydrofluoric acid to prepare a solution containing the graphite fiber.

[0030] (3) Place the solution added with graphite fibers in a magnetic stirrer, and stir evenly by magnetic stirring for 4 hours.

[0031] (4) Next, the stirred solution containing the graphene fibers was placed in a hydrothermal reactor for 48 hours of reaction, and the reaction temperature in the hydrothermal reactor was 200°C.

[0032] (5) Finally, filter the solution after the reaction to obtain the generated precipitate, wash the precipitate with deionized water, and dry it to obtain graphene grown ...

Embodiment 2

[0036] (1) Measure 10 g of concentrated sulfuric acid and 50 g of hydrofluoric acid, pour the concentrated sulfuric acid and hydrofluoric acid into a beaker, mix the concentrated sulfuric acid and hydrofluoric acid evenly and configure a mixed solvent with a mass ratio of 1:5, and Measure 50 g from 60 g of the mixed solvent.

[0037] (2) Weigh 1 g of graphite fiber and disperse the graphite fiber in a mixed solvent of 50 g of concentrated sulfuric acid and hydrofluoric acid to prepare a solution containing the graphite fiber.

[0038] (3) Place the solution added with graphite fibers in a magnetic stirrer, and stir evenly by magnetic stirring for 4 hours.

[0039] (4) Next, the stirred solution containing the graphene fibers was placed in a hydrothermal reactor for 48 hours of reaction, and the reaction temperature in the hydrothermal reactor was 200°C.

[0040] (5) Finally, filter the solution after the reaction to obtain the generated precipitate, wash the precipitate with ...

Embodiment 3

[0044] (1) Measure 50 g of vitriol oil, 10 g of hydrofluoric acid, pour the vitriol oil and hydrofluoric acid into a beaker, mix the vitriol oil and hydrofluoric acid evenly and configure a mixed solvent with a mass ratio of 5:1, and Measure 50 g from 60 g of the mixed solvent.

[0045] (2) Weigh 1 g of graphite fiber and disperse the graphite fiber in a mixed solvent of 50 g of concentrated sulfuric acid and hydrofluoric acid to prepare a solution containing the graphite fiber.

[0046] (3) Place the solution added with graphite fibers in a magnetic stirrer, and stir evenly by magnetic stirring for 4 hours.

[0047] (4) Next, the stirred solution containing graphene fibers was placed in a hydrothermal reactor for 48 hours of reaction, and the reaction temperature in the hydrothermal reactor was 200°C.

[0048] (5) Finally, filter the solution after the reaction to obtain the generated precipitate, wash the precipitate with deionized water, and dry it to obtain graphene grown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com