Light stabilizer and preparation method thereof

A light stabilizer and desolventizing technology, applied in the preparation of light stabilizers and the field of light stabilizers, can solve the problems of single light stabilization function, enhance the anti-aging effect of light stabilizers, and have little effect, and achieve high-efficiency light stabilization. performance, optimized production methods, high value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

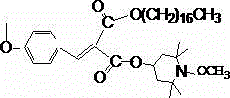

Image

Examples

Embodiment 1

[0029] The preparation method of light stabilizer 726 of the present invention:

[0030] (1) In a 500ml four-necked bottle equipped with a condenser, a water separator, a foam puff, a reflux tube, a thermometer and an agitator, and assembled according to a conventional method, quantify 25.1g of 4-methoxy Dimethyl benzylidene malonate, 18.5g methoxy piperidinol and 45g mineral spirits are put into the synthesis kettle;

[0031] (2) Start the agitator, heat to 110°C at 200 revolutions per minute, add 0.3g of lithium amide catalyst, start reflux to demethanolize until the reflux sight glass becomes clear, and the reaction time is 5 hours;

[0032] (3) Add 27.5g of molten stearyl alcohol dropwise. After methanol starts to come out, continue to reflux the demethanol until it becomes clear on the reflux sight glass. The reaction time is 5 hours; the sampling test is qualified; then filter and desolventize and use molecular distillation , the vacuum degree during molecular distillat...

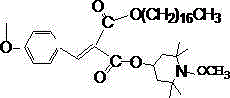

Embodiment 2

[0035] (1) In a 500ml four-necked bottle equipped with a condenser, a water separator, a foam puff, a reflux tube, a thermometer and an agitator, and assembled according to a conventional method, quantify 38g of 4-methoxy Dimethyl benzylidene malonate, 27.8g methoxypiperidinol and 160g mineral spirits are put into the synthesis kettle;

[0036] (2) Start the agitator, heat to 120°C at 240 revolutions per minute, add 0.5 g of sodium methoxide catalyst, and start reflux to demethanolize until the reflux sight glass becomes clear. The reaction time is 3 hours;

[0037] (3) Add 42.5g of molten stearyl alcohol dropwise. After the methanol starts to come out, continue to reflux the demethanol until it becomes clear on the reflux mirror. The reaction time is 5 hours. Distillation, vacuum degree during molecular distillation reaches 40Pa, temperature is 90 ℃, obtains qualified product.

[0038] The light stabilizer 726 prepared in this example has a product yield of 92% and a mixed e...

Embodiment 3

[0040] (1) In a 1000ml four-necked bottle equipped with a condenser, a water separator, a foam puff, a reflux tube, a thermometer and an agitator, and assembled according to a conventional method, quantify 125g of 4-methoxy Dimethyl benzylidene malonate, 42.5g methoxy piperidinol and 350g mineral spirits are put into the synthesis kettle;

[0041] (2) Start the agitator, heat at 220 rpm to 115°C under the reaction conditions, add 0.5g of sodium methoxide catalyst, start reflux to remove methanol until the reflux sight glass becomes clear, and the reaction time is 4 hours;

[0042] (3) Add 68g of molten stearyl alcohol dropwise. After methanol starts to come out, continue to reflux to remove methanol until it becomes clear on the reflux mirror. The reaction time is 6 hours. , the vacuum degree during molecular distillation reaches 30Pa, the temperature is 90°C, and qualified products are obtained.

[0043] The light stabilizer 723 prepared in this example has a product yield o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com