Biodegradable plastic cement material and preparation method thereof

A plastic material, biodegradable technology, applied in the field of materials, can solve the problems of white pollution, low degradability, visual impact, etc., and achieve the effect of high tensile strength and elongation at break, good elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

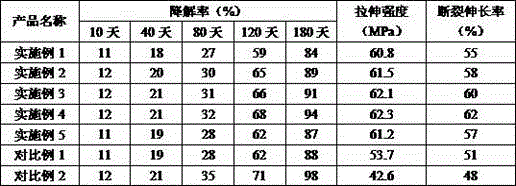

Examples

Embodiment 1

[0017] A biodegradable plastic material, comprising in parts by weight: 20 parts of polylactic acid, 10 parts of polymethyl methacrylate, 5 parts of polypropylene, 0.5 part of dioctyl phthalate, butyl benzyl phthalate 0.1 part of ester, 2 parts of castor oil, 1 part of coconut oil fatty acid diethanolamide, 1 part of cellulose, 1 part of modified starch, 0.2 part of dibutyl hydroxytoluene, 0.1 part of butyl hydroxyanisole, 0.5 part of polymethyl acrylate parts, 0.5 parts of silicon dioxide.

[0018] The preparation method of the above-mentioned biodegradable plastic material is as follows: first polylactic acid, polymethyl methacrylate, polypropylene, dioctyl phthalate, butyl benzyl phthalate, castor oil and coconut oil fatty acid Mix ethanolamide, heat to 80°C and stir for 1 hour, then add the remaining components, use a low-speed disperser to disperse at a speed of 300r / min for 2 minutes, put it in an oven and react at 80°C for 2 hours, and finally add twin-screw extrusion ...

Embodiment 2

[0020] A biodegradable plastic material, comprising in parts by weight: 25 parts of polylactic acid, 15 parts of polymethyl methacrylate, 7.5 parts of polypropylene, 0.7 part of dioctyl phthalate, butyl benzyl phthalate 0.15 parts of ester, 3.5 parts of castor oil, 1.5 parts of coconut oil fatty acid diethanolamide, 1.5 parts of cellulose, 1.5 parts of modified starch, 0.3 parts of dibutyl hydroxytoluene, 0.15 parts of butyl hydroxyanisole, 0.7 parts of polymethyl acrylate parts, 0.7 parts of silicon dioxide.

[0021] The preparation method of the above-mentioned biodegradable plastic material is as follows: first polylactic acid, polymethyl methacrylate, polypropylene, dioctyl phthalate, butyl benzyl phthalate, castor oil and coconut oil fatty acid Mix ethanolamide, heat to 85°C and stir for 1.5 hours, then add the remaining components, use a low-speed disperser to disperse at a speed of 350r / min for 3 minutes, put it in an oven and react at 85°C for 2.5 hours, and finally ad...

Embodiment 3

[0023] A biodegradable plastic material, comprising in parts by weight: 30 parts of polylactic acid, 20 parts of polymethyl methacrylate, 10 parts of polypropylene, 1 part of dioctyl phthalate, butyl benzyl phthalate 0.2 parts of ester, 5 parts of castor oil, 2 parts of coconut oil fatty acid diethanolamide, 2 parts of cellulose, 2 parts of modified starch, 0.5 parts of dibutyl hydroxytoluene, 0.2 parts of butyl hydroxyanisole, 1 part of polymethyl acrylate 1 part, 1 part of silicon dioxide.

[0024] The preparation method of the above-mentioned biodegradable plastic material is as follows: first polylactic acid, polymethyl methacrylate, polypropylene, dioctyl phthalate, butyl benzyl phthalate, castor oil and coconut oil fatty acid Mix ethanolamide, heat to 90°C and stir for 2 hours, then add the remaining components, use a low-speed disperser to disperse at a speed of 400r / min for 5 minutes, put it in an oven and react at 90°C for 3 hours, and finally add twin-screw extrusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com