Ink and preparation method thereof and printing process using ink

An ink, ink-based technology, applied in printing, ink, application, etc., can solve the problem of light color of ink, and achieve the effect of bright color, high brightness and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

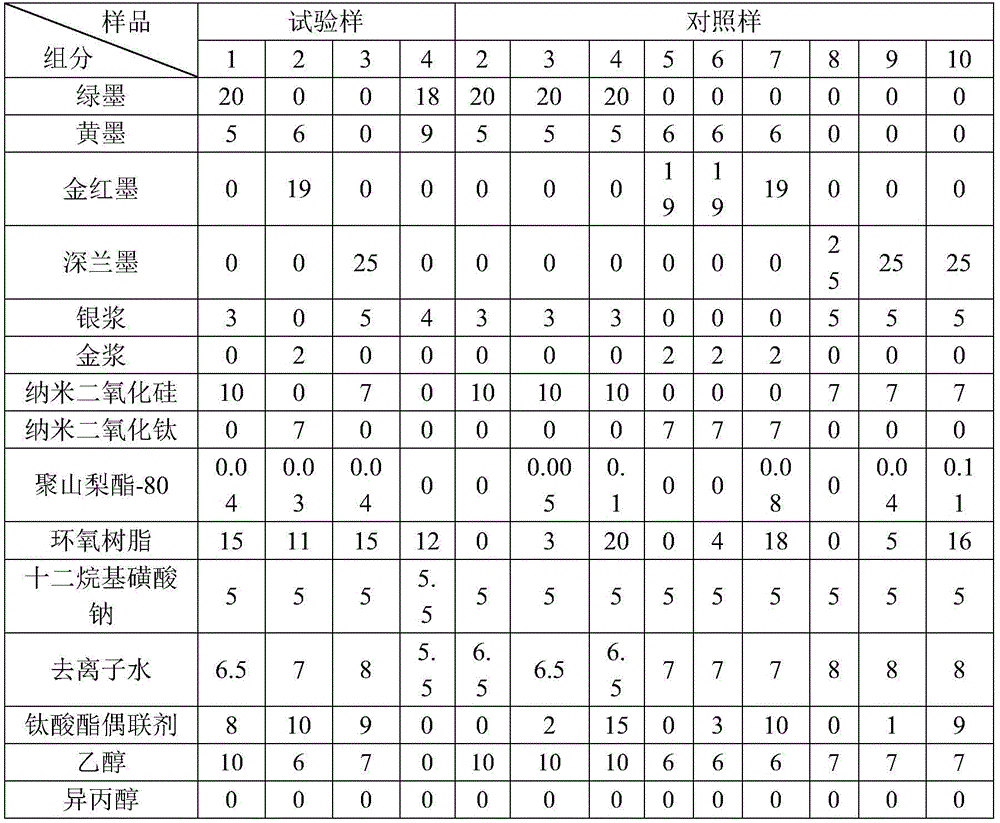

[0046] The preparation method of embodiment 1-13:

[0047] S1. Pre-dispersion: Weigh the diluent (epoxy resin, sodium dodecyl sulfonate and deionized water) according to the corresponding parts by weight, treat the diluent with ultrasonic waves for 10-15min, and then add the corresponding metal parts by weight Add slurry (gold paste or silver paste), adsorbent (nano-silicon dioxide or nano-titanium dioxide), dispersant (ethanol or isopropanol), titanate coupling agent and polysorbate-80 to the diluent, and then After ultrasonic treatment for 20-25min;

[0048] S2. Pre-mixing: put the ink base of the corresponding weight in a 280-400r / min stirrer and stir, slowly add the ultrasonically treated mixture in S1 while stirring, and stir at a speed of 450-500r / min after the addition is complete 30-35min;

[0049] S3. Packaging: put the final product obtained in S2 into a packaging barrel.

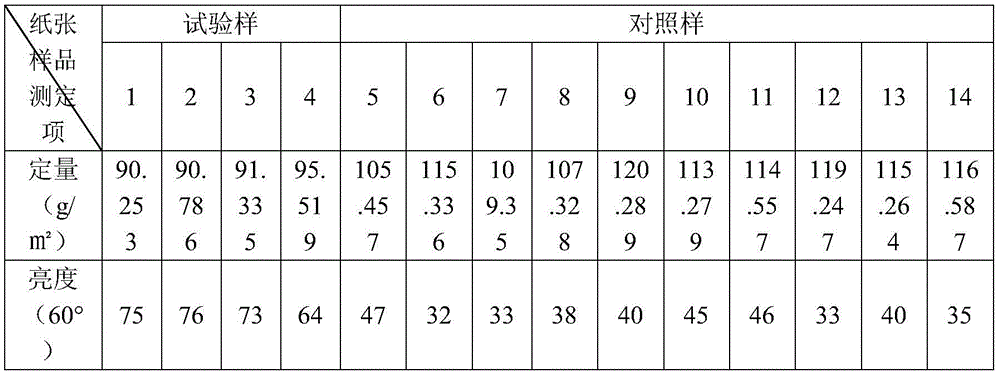

[0050] The ink prepared according to Examples 1-13 has bright colors. Components and their...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com