Pinhole array miniature electrostatic electric thruster

A small hole array and electric thruster technology, which is applied to thrust reversers, machines/engines, and the use of plasma, can solve the problems of long development cycle, low thrust adjustment capability, and high cost, and achieve easy mass production and improved The effect of reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

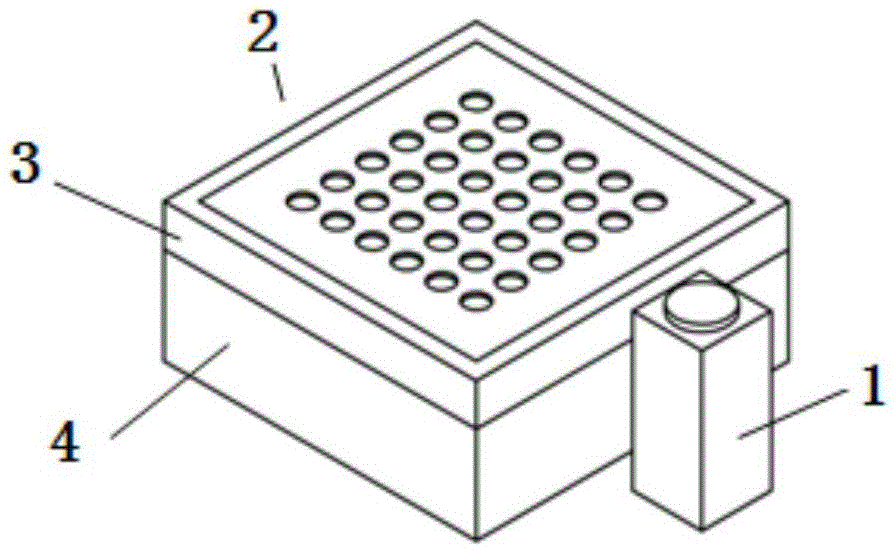

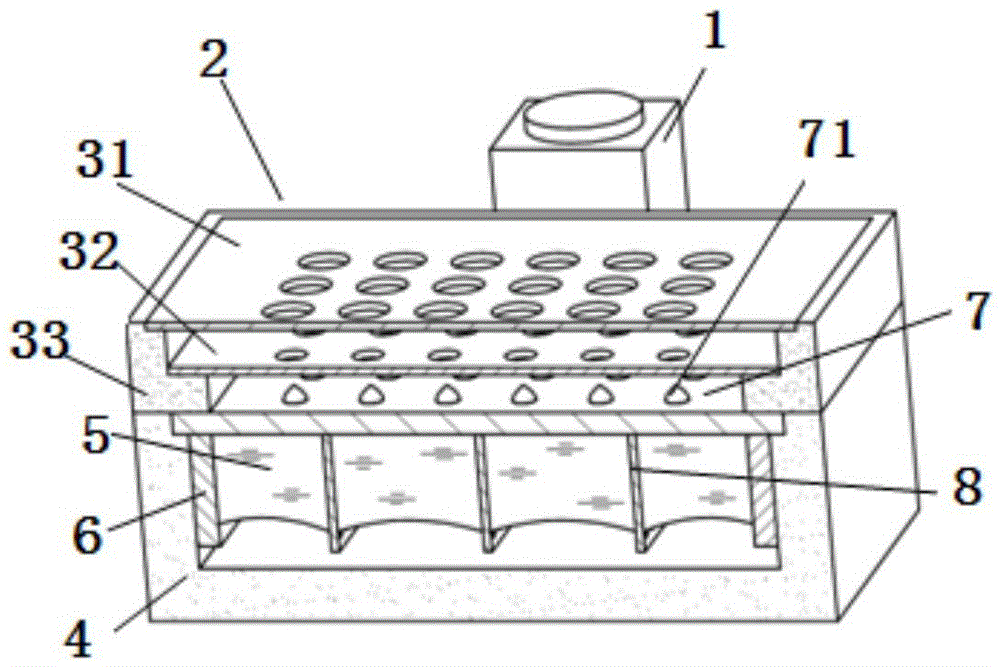

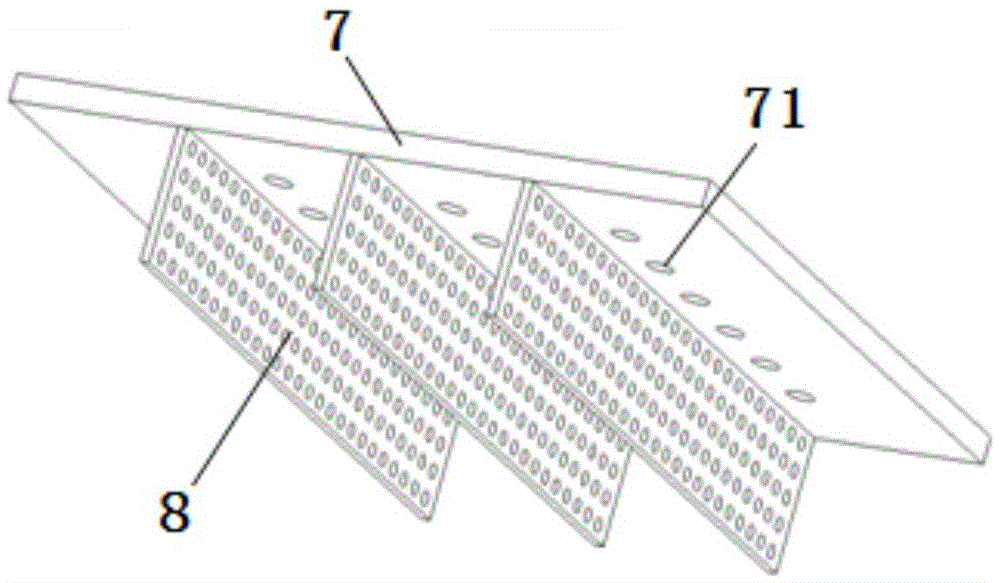

[0031] Such as Figure 1-3 As shown, the small hole array miniature electrostatic thruster 2 of this embodiment adopts two grids of the extraction grid 32 and the acceleration grid 31, the transport plate 8 adopts a small hole array sheet transport plate, and the propellant 5 is added with lithium chloride Solute solution in formamide. The insulating support 33 is an integral structure. A total of 36 small holes 71 in 6 rows and 6 columns are distributed on the small hole array plate 7 in an array. Below the small hole array plate 7 are three transport plates 8, and two adjacent transport plates 8 are separated by two rows. Small hole 71. An array of small holes is distributed on the transport plate 8 to improve the effect of capillary action, and the propellant is adsorbed and transported through the capillary action. There are 36 holes distributed on the lead-out grid 32 and the acceleration grid 31 , and the axial direction of each hole coincides with the corresponding h...

Embodiment 2

[0033] The aperture array miniature electrostatic thruster of this embodiment adopts a single grid 9 to realize the extraction and acceleration of charged droplets, and utilizes a porous material transport plate, and the propellant is a formamide solution added with lithium chloride solute ( Figure 4 ). A total of 36 small holes in 6 rows and 6 columns are distributed on the small hole array plate in an array form. Below the small hole array plate are three transport plates 8 , and two adjacent transport plates 8 are separated by two rows of small holes. The porous material transport plate can greatly increase the contact area with the propellant, and the fine gaps of the porous material are conducive to enhancing capillary action, so as to better absorb and transport the propellant. There are 36 holes distributed on the grid, and the axial direction of each hole coincides with the corresponding hole on the small hole array plate. The pinhole array plate has a higher voltage...

Embodiment 3

[0035] The small hole array miniature electrostatic thruster of this embodiment adopts a neutralizer with the same or similar structure as the main body, and the propellant is [EMIm]BF 4 The power connection method of the ionic liquid and the neutralizer is the same as that of the main body except for the positive and negative polarity. The positive and negative polarity of the neutralizer is opposite to that of the body. The neutralizer and the small hole array plate of the main body are directly connected on the circuit. The positive and negative polarities of the charged droplets ejected from the neutralizer and the body are opposite. For example, the charged droplets emitted by the body are positively charged, and the charged droplets emitted by the neutralizer are negatively charged; or, the charged droplets emitted by the body are positively charged , the charged droplets of the neutralizer are negatively charged. In this way, when the small hole array miniature electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com