Series combining method for siphoning type pasty material heat exchangers

A series combination and heat exchanger technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of inability to realize the series combination of vertical slurry material heat exchangers, and save energy. The effect of consumption, reducing power equipment, saving power and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: slurry cooling. The slurry in this example is obtained from mineral processing, its suspended solids content is 35% (mass percentage), and the average density of the slurry is 1400kg / m 3 , in the slurry tank 4, the temperature is 95°C, the saturated vapor pressure is 40kPa (absolute pressure), and the material level is maintained at 11.0m. It is required to cool down the slurry to 80°C before entering the delivery pump 8, and the material level of the slurry tank 7 connected to the inlet of the pump 8 is not lower than 3.0m. The flow rate of the slurry delivered by the pump 8 is 860 tons / hour (t / h).

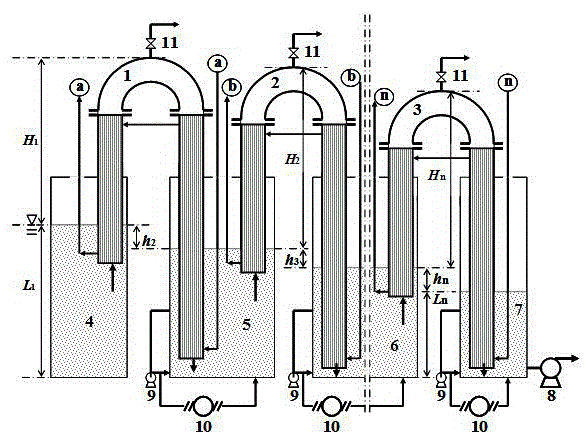

[0014] As shown in the drawings, a convective heat transfer and cooling device with three ∩-type heat exchangers connected in series is arranged between the slurry tank 4 and the slurry tank 7 . The structure and size of the three ∩-type heat exchangers are the same. The inlet and outlet shell-and-tube heat exchanger tubes are composed of 220 heat exchange ...

Embodiment 2

[0016] Example 2: multistage flash evaporation of slurry. The slurry in this example is obtained from mineral processing, its suspended solids content is 16% (mass percentage), and the average density of the slurry is 1100kg / m 3 , in the slurry tank 4, the temperature is 65°C, the saturated vapor pressure is 22kPa (absolute pressure), and the material level is maintained at 11.0m. It is required to separate part of the solvent by multi-stage flash evaporation before entering the transfer pump 8. The flow rate of the delivery pump 8 is 178 tons / hour (t / h).

[0017] As shown in the figure, a three-stage flash evaporation and convection heating device in which three ∩-type heat exchangers are connected in series are arranged between the slurry tank 4 and the slurry tank 7 . The structure and size of the three ∩-type heat exchangers are the same. The tube side of the shell-and-tube heat exchanger at the inlet and outlet ends is composed of 62 heat exchange tubes with a length of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com