Porous dental implant capable of carrying drug sustained release system and manufacturing method thereof

A technique for dental implants and manufacturing methods, which is applied in the field of porous dental implants and its manufacturing, can solve the problems of difficulty in realizing porous structures, poor rapidity, and poor bonding strength, and achieve improved long-term effectiveness, easy implementation, and improved The effect of binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

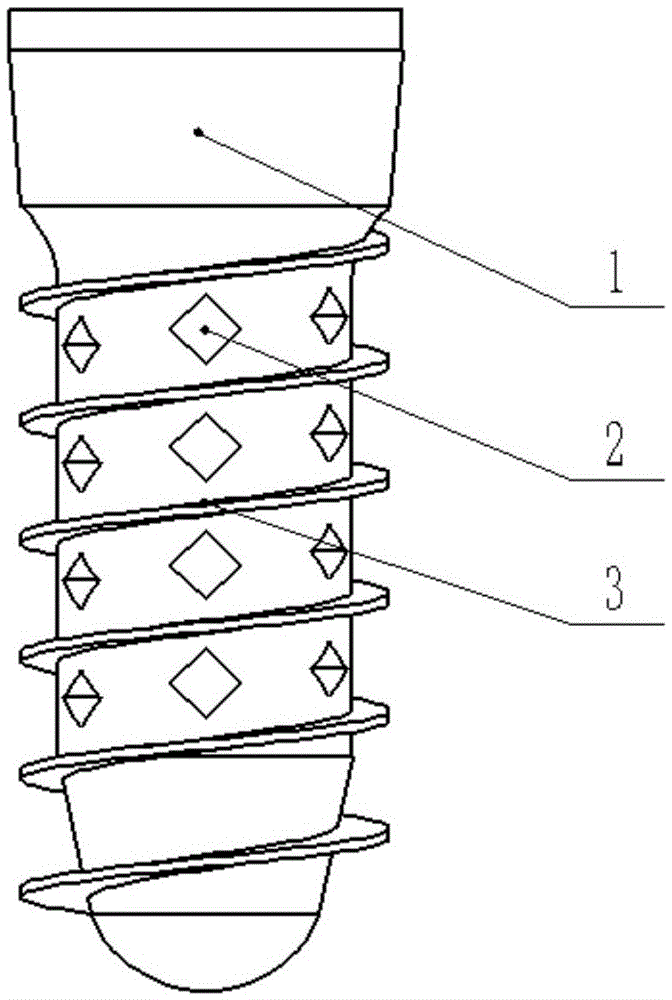

[0051] Example: such as figure 1 Shown is a two-dimensional structural schematic diagram of a porous dental implant that can carry a drug sustained release system. The main body of the implant is a structure of revolution, with a thread between the neck and the root, and the outer diameter of the thread is the same as the diameter of the implant neck. In the middle part of the implant, a porous structure is created at the thread intervals. The implant size is 3.75*10mm, the neck diameter is 3.75mm, and the length is 10mm. The cross-sectional area of a single hole in the porous structure is rhombus, its diagonal length is 0.5 mm, and its depth is also 0.5 mm. The holes are uniformly distributed at equal intervals in the axial direction, and are helically distributed in the circumferential direction, and a hole is established every 60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com