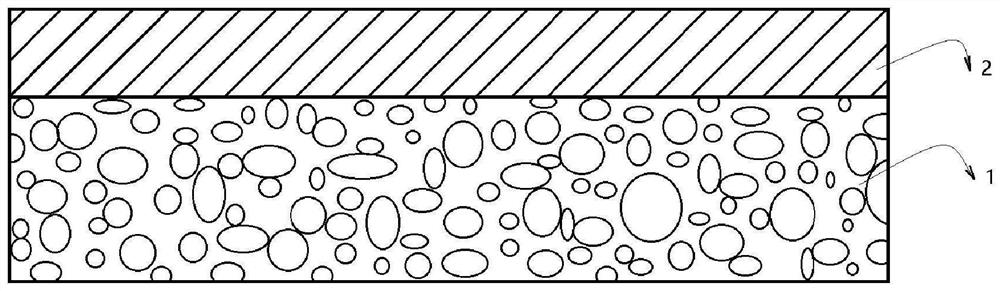

A double-layer periosteum for diabetic bone repair and its preparation method

A double-layer structure, diabetic bone technology, applied in prosthesis, tissue regeneration, medical science, etc., can solve the problems of lack of periosteum regeneration structure and function, achieve excellent biodegradability and absorbability, good antibacterial ability, excellent degradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

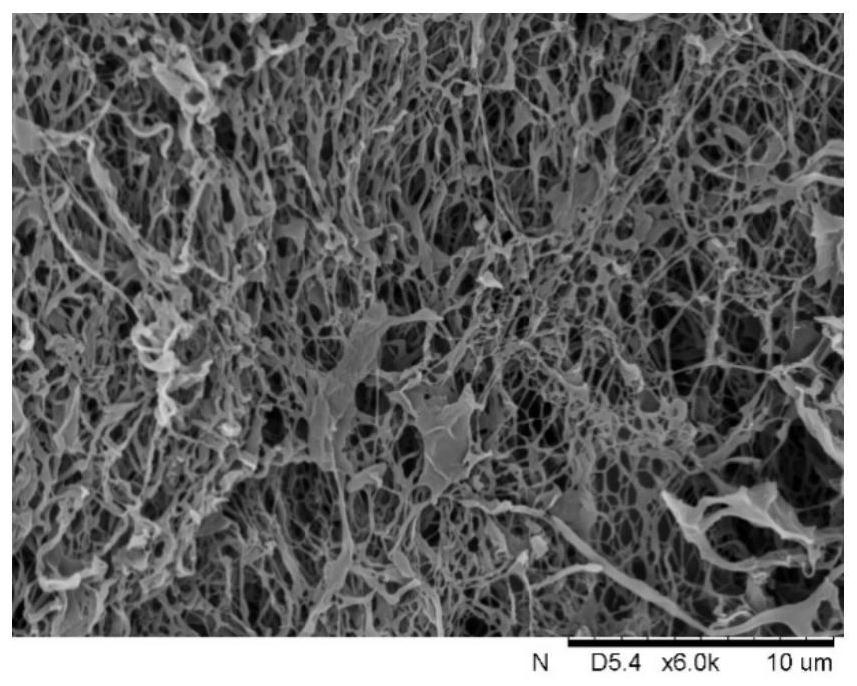

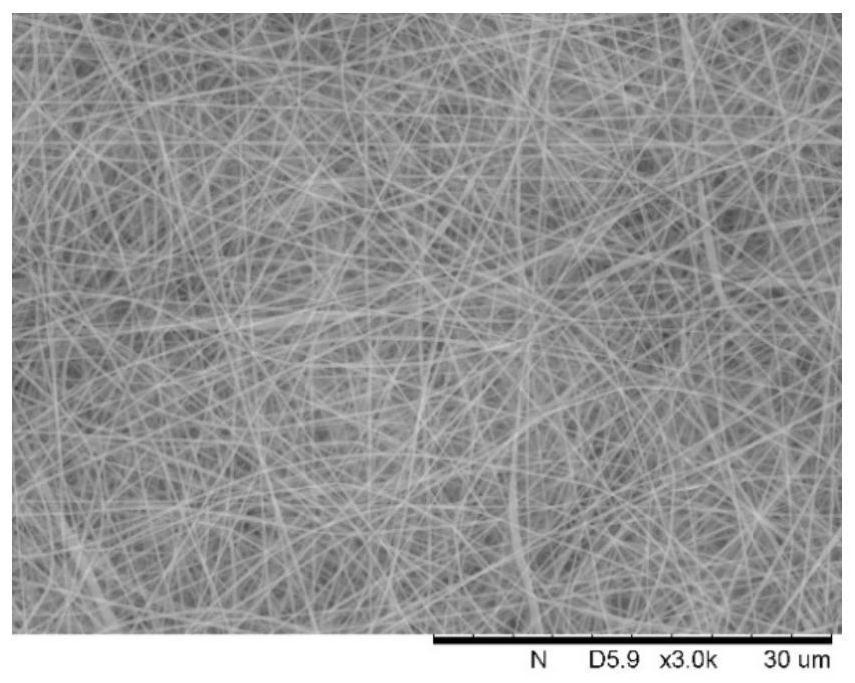

[0030] Step 1: Preparation of inner layer:

[0031] Add chitosan (CS) and polyvinyl alcohol (PVA) to 20% acetic acid solution at a mass percentage of 10:90 to prepare a 10% solution, and stir in a water bath at a temperature of 90°C for more than 12 hours , after the obtained solution was allowed to stand for cooling, 5 μL of calycosin with a concentration of 40 mmol / L was added, and stirred at room temperature for 6 hours to obtain the electrospinning solution of the inner layer;

[0032] Using an electrospinning device, control the receiving distance to 16cm, the voltage to 18KV, the liquid flow rate to 0.3ml / h, and a 20G flat needle to obtain the inner nanofiber membrane by electrospinning under the condition of a relative humidity of 30%;

[0033] Select 25% glutaraldehyde solution to crosslink the obtained nanofiber membrane for 1 hour, then dry it in a vacuum oven at 50°C for 30 minutes, cut the crosslinked nanofiber membrane into pieces, and add a volume ratio of 20:80...

Embodiment 2

[0039] Step 1: Preparation of inner layer:

[0040]Add chitosan (CS) and polyvinyl alcohol (PVA) to 20% acetic acid solution at a mass percentage of 20:80 to prepare a 10% solution, and stir in a water bath at a temperature of 90°C for more than 12 hours After the obtained solution was allowed to stand and cool, 7uL of calycosin with a concentration of 40mmol / L was added, and stirred at room temperature for 6h to obtain the electrospinning solution of the inner layer;

[0041] An electrospinning device is used to control the receiving distance of 17cm, voltage of 19KV, liquid flow rate of 0.45mL / h, 20G flat needle, and electrospinning under the condition of relative humidity of 30% to obtain the nanofiber film of the inner layer;

[0042] Select the glutaraldehyde solution with a concentration of 25% to carry out crosslinking treatment on the obtained nanofiber membrane for 1 hour, then dry it in a vacuum oven at 50°C for 30 minutes, cut the crosslinked nanofiber membrane into...

Embodiment 3

[0048] Step 1: Preparation of inner layer:

[0049] Add chitosan (CS) and polyvinyl alcohol (PVA) to the acetic acid solution with a concentration of 20% at a mass percentage of 30:70 to prepare a solution with a concentration of 10%, and stir in a water bath at a temperature of 90°C for more than 12 hours , after the obtained solution was allowed to stand for cooling, 9 μL of calycosin with a concentration of 40 mmol / L was added, and stirred at room temperature for 6 hours to obtain the electrospinning solution of the inner layer;

[0050] Using an electrospinning device, control the receiving distance of 18cm, voltage of 20KV, liquid flow rate of 0.6ml / h, 20G flat needle, and obtain the inner nanofiber membrane by electrospinning under the condition of relative humidity of 30%;

[0051] Select the glutaraldehyde solution with a concentration of 25% to crosslink the obtained nanofiber membrane for 1 hour, then dry it in a vacuum oven at 50°C for 30 minutes, cut the crosslinke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com