Preparation method of crosslinked chitosan/hyaluronic acid compound porous scaffold

A technology of cross-linking chitosan and hyaluronic acid, which is applied in the fields of medical science and prostheses, can solve the problems of weak mechanical strength, achieve good mechanical properties, good affinity, and facilitate proliferation and differentiation growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

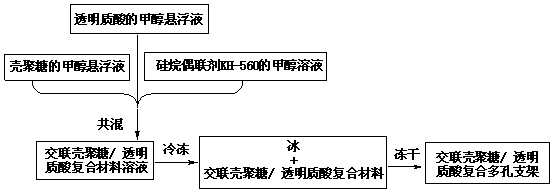

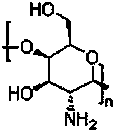

[0023] The methanol suspension of 2% chitosan, the methanol suspension of hyaluronic acid and the methanol solution of silane coupling agent KH-560 were configured respectively;

[0024] The methanol suspension of chitosan, the methanol suspension of hyaluronic acid and the methanol solution of silane coupling agent KH-560 were blended at a mass ratio of 35:35:30, heated to 70°C, and stirred for 3 hours. Suction filtration, repeated washing with anhydrous methanol until the unreacted silane coupling agent KH-560 is washed away, and vacuum-dried at 60°C for 24 hours to obtain a cross-linked chitosan / hyaluronic acid composite material;

[0025] With above-mentioned cross-linked chitosan / hyaluronic acid composite material, be dissolved in 100g distilled water, prepare the aqueous solution that mass percent is 1% cross-linked chitosan / hyaluronic acid composite material, defoaming, obtain the deaeration after Aqueous solution of cross-linked chitosan / hyaluronic acid composite;

[...

Embodiment 2

[0029] Same as Example 1, but the methanol suspension of chitosan, the methanol suspension of hyaluronic acid and the concentration of the methanol solution of silane coupling agent KH-560 in step (1) all become 3% by 2%, other constant.

Embodiment 3

[0031] Same as Example 1, but the methanol suspension of chitosan in step (1), the methanol suspension of hyaluronic acid and the concentration of the methanol solution of silane coupling agent KH-560 all become 1% by 2%, other constant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com