Method for processing of unreacted ammonia in acrylonitrile reaction device

A technology of a reaction device and a treatment method, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high energy consumption, incomplete absorption of unreacted ammonia, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

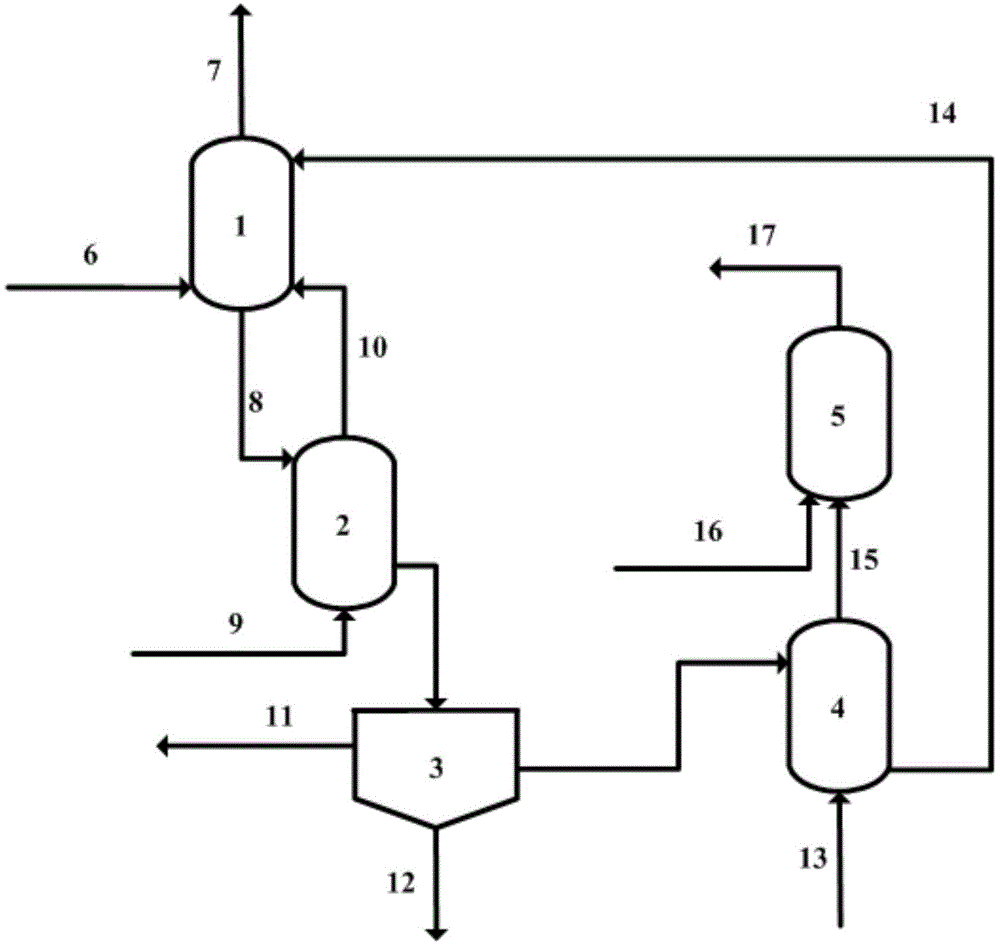

Method used

Image

Examples

Embodiment 1

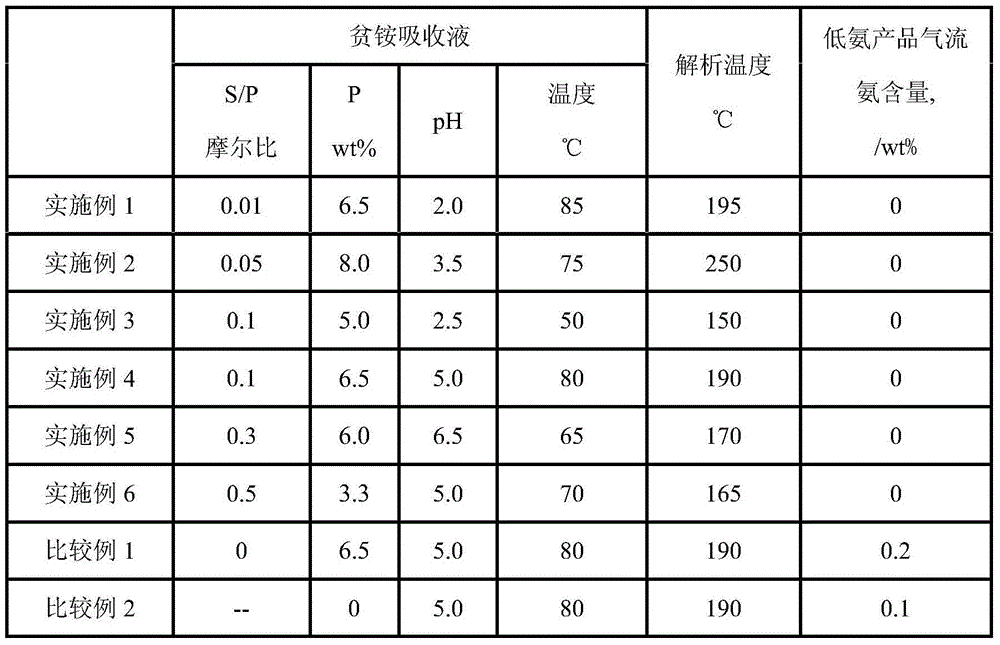

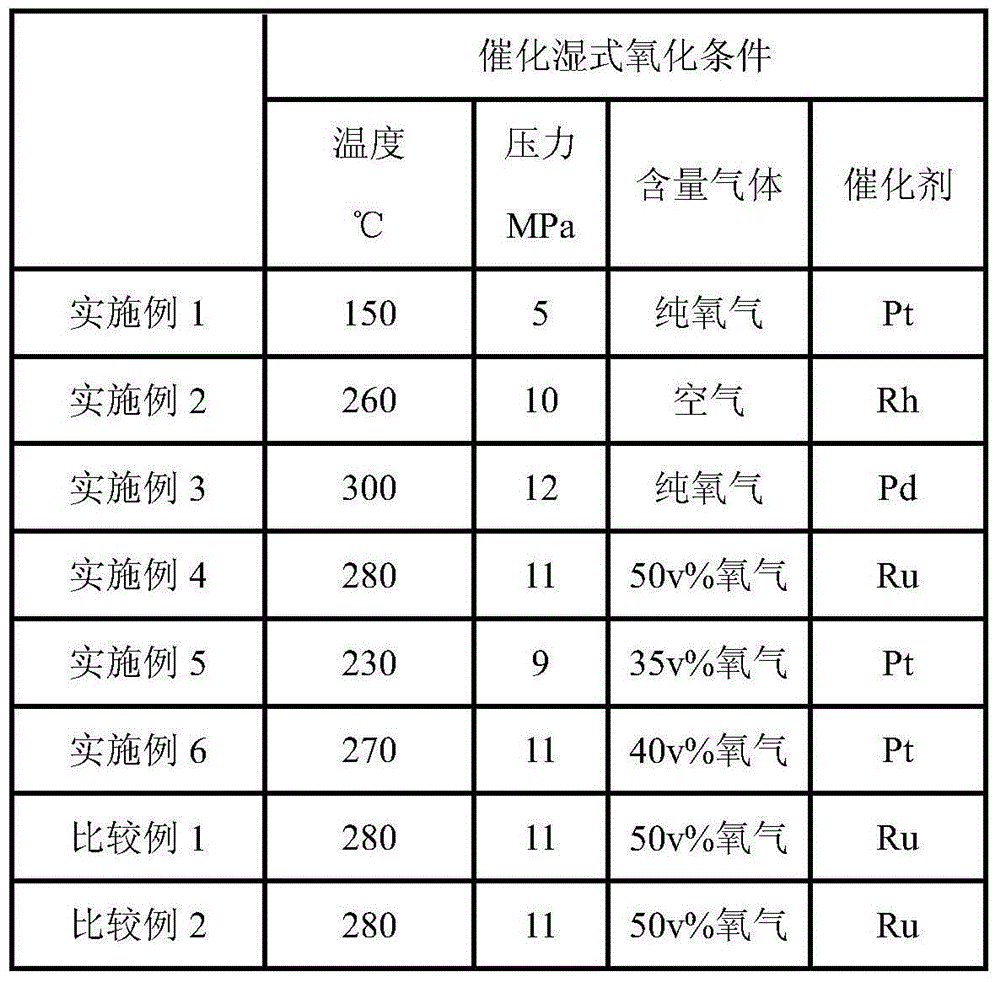

[0030] The high-ammonia product gas stream from the propylene ammoxidation reactor is contacted with the poor ammonium absorption liquid in the quench tower to absorb unreacted ammonia to obtain a low-ammonia product gas stream and a rich ammonium absorption liquid. The S / P molar ratio in the poor ammonium absorption liquid is 0.01, and the phosphorus The mass content of the element is 6.5%, the pH value of the absorption liquid is 2, the temperature of the ammonium-poor absorption liquid is 85° C., and the content of ammonia in the low-ammonia product gas stream obtained through absorption is detected to be 0. The ammonium-rich absorption liquid enters the separation device after being stripped by steam stripping gas in the stripping tower to remove light components and heavy components including catalysts and / or polymers, and then enters the desorption tower for analysis to obtain crude ammonia gas stream and ammonium-poor The absorption liquid, the operating temperature of t...

Embodiment 2

[0033] The high-ammonia product gas stream from the propylene ammoxidation reactor is contacted with the poor ammonium absorption liquid in the quench tower to absorb unreacted ammonia to obtain a low-ammonia product gas stream and a rich ammonium absorption liquid. The S / P molar ratio in the poor ammonium absorption liquid is 0.05, and the phosphorus The mass content of the element is 8.0%, the pH value of the absorption liquid is 3.5, the temperature of the ammonium-poor absorption liquid is 75° C., and the content of ammonia in the low-ammonia product gas stream obtained through absorption is detected to be 0. The ammonium-rich absorption liquid enters the separation device after being stripped by air in the stripping tower to remove light components and heavy components including catalysts and / or polymers, and then enters the desorption tower for analysis to obtain crude ammonia gas flow and ammonium-poor absorption liquid. The operating temperature of the tower is 250°C, a...

Embodiment 3

[0036] The high-ammonia product gas stream from the propylene ammoxidation reactor is contacted with the poor ammonium absorption liquid in the quench tower to absorb unreacted ammonia to obtain a low-ammonia product gas stream and a rich ammonium absorption liquid. The S / P molar ratio in the poor ammonium absorption liquid is 0.1, and the phosphorus The element mass content is 5.0%, the pH value of the absorption solution is 2.5, the temperature of the ammonium-poor absorption solution is 50° C., and the ammonia content in the low-ammonia product gas stream obtained through absorption is detected to be 0. The ammonium-rich absorption liquid enters the separation device after being stripped by nitrogen in the stripping tower to remove light components and heavy components including catalysts and / or polymers, and then enters the analysis tower for analysis to obtain crude ammonia gas flow and ammonium-poor absorption liquid. The operating temperature of the tower is 150°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com