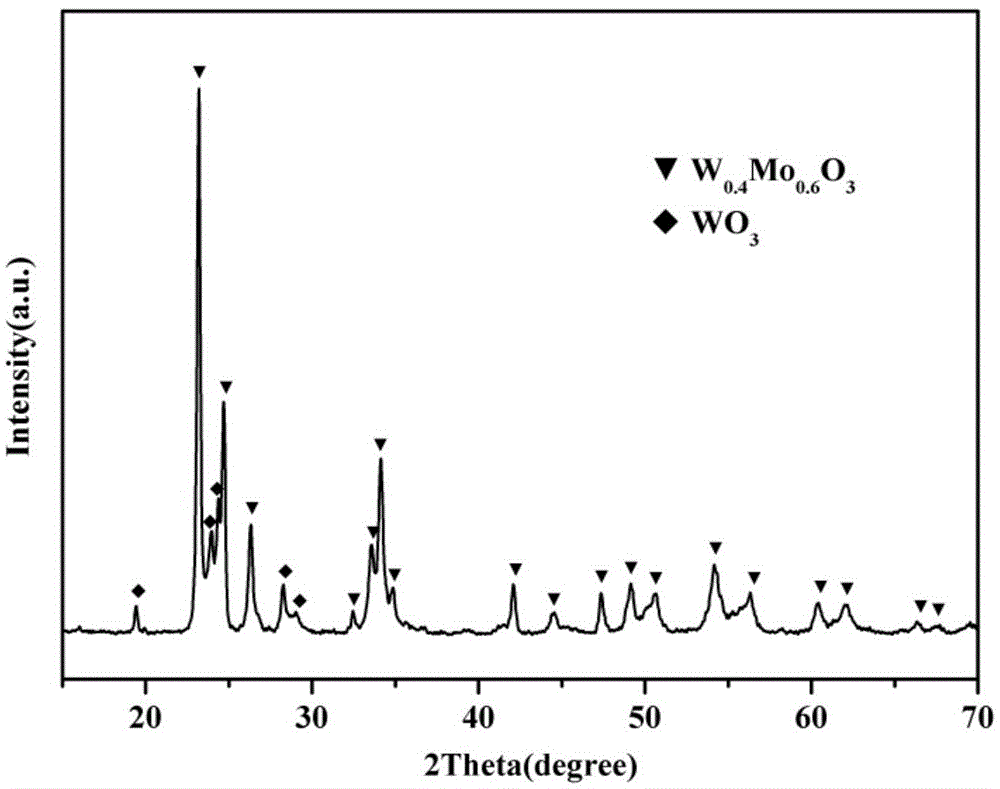

Preparation method of high-performance nano W0.4Mo0.6O3 photocatalyst

A photocatalyst, high-performance technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. less problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

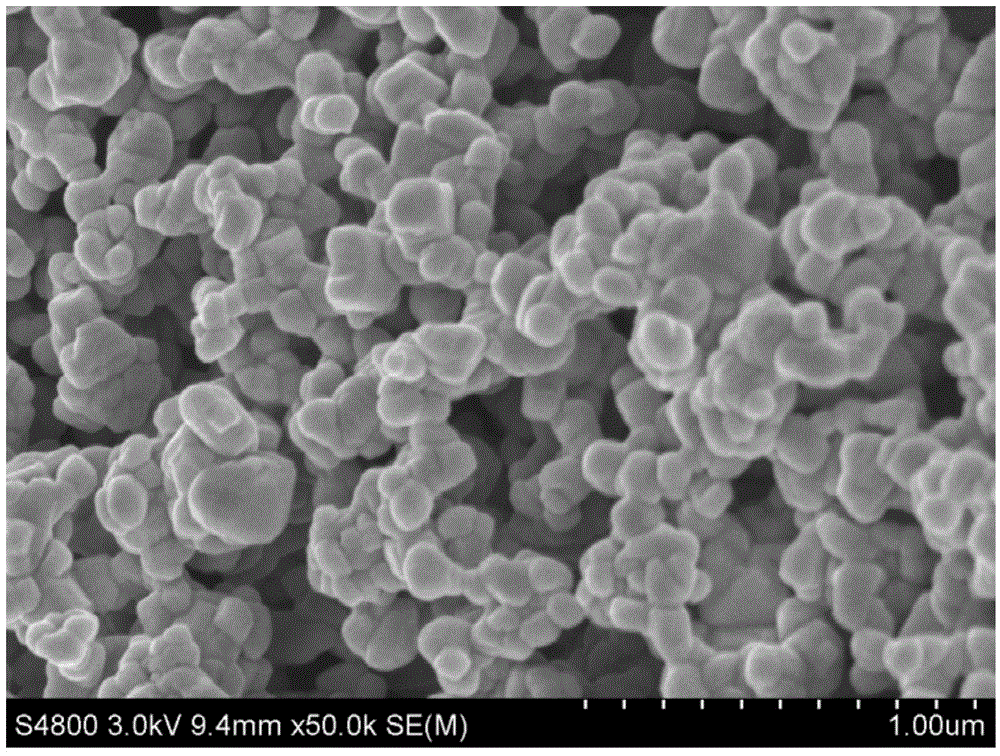

Image

Examples

Embodiment 1

[0022] 1) Prepare 0.5mol / L of C 6 H 12 O 6 ·H 2 O (glucose) distilled water, 0.2mol / L Na 2 WO 4 2H 2 O distilled water, 0.2mol / L Na 2 MoO 4 2H 2 O distilled aqueous solution and 0.01mol / L polyoxyethylene fatty alcohol ether distilled aqueous solution.

[0023] 2) Dilute the above solution in molar ratio C 6 H 12 O 6 ·H 2 O:Na 2 WO 4 2H 2 O:Na 2 MoO 4 2H 2O=2:1:1 ratio mixed, stirred at 40°C for 30min to obtain a mixed solution. Then add polyoxyethylene fatty alcohol ether distilled aqueous solution to the mixed solution, and stir at 40 for 20 minutes. Wherein, the volume of the polyoxyethylene fatty alcohol ether distilled aqueous solution is 1% of the volume of the mixed solution.

[0024] 3) Adjust the pH to 1 with hydrochloric acid with a concentration of 2 mol / L.

[0025] 4) Then pour it into a polytetrafluoroethylene-lined high-pressure hydrothermal reactor, keeping the volume filling ratio at 50%.

[0026] 5) Put the sealed reaction kettle into a ho...

Embodiment 2

[0032] 1) Prepare 0.8mol / L of C 6 H 12 O 6 ·H 2 O distilled water, 0.5mol / L Na 2 WO 4 ·2H 2 O distilled water, 0.5mol / L Na 2 MoO 4 ·2H 2 O distilled aqueous solution and 0.03mol / L polyoxyethylene fatty alcohol ether distilled aqueous solution.

[0033] 2) Dilute the above solution in molar ratio C 6 H 12 O 6 ·H 2 O:Na 2 WO 4 ·2H 2 O:Na 2 MoO 4 ·2H 2 O=3:1:1 ratio mixed, stirred at 45°C for 25min to obtain a mixed solution. Then, distilled aqueous solution of polyoxyethylene fatty alcohol ether was added to the mixed solution, and stirred at 45° C. for 15 minutes. Wherein, the volume of polyoxyethylene fatty alcohol ether distilled aqueous solution is 1.5% of the mixed solution volume.

[0034] 3) Adjust the pH to 1.5 with hydrochloric acid with a concentration of 2 mol / L.

[0035] 4) Then pour it into a polytetrafluoroethylene-lined high-pressure hydrothermal reactor, keeping the volume filling ratio at 60%.

[0036] 5) Put the sealed reactor into a homog...

Embodiment 3

[0040] 1) Prepare 1mol / L of C 6 H 12 O 6 ·H 2 O distilled water, 0.8mol / L Na 2 WO 4 ·2H 2 O distilled water, 0.8mol / L Na 2 MoO 4 ·2H 2 O distilled aqueous solution and 0.05mol / L polyoxyethylene fatty alcohol ether distilled aqueous solution.

[0041] 2) Dilute the above solution in molar ratio C 6 H 12 O 6 ·H 2 O:Na 2 WO 4 ·2H 2 O:Na 2 MoO 4 ·2H 2 O=4:1:1 ratio mixed, stirred at 50°C for 20min to obtain a mixed solution. Then add polyoxyethylene fatty alcohol ether distilled aqueous solution to the mixed solution, and stir at 50° C. for 10 min. Wherein, the volume of polyoxyethylene fatty alcohol ether distilled aqueous solution is 2% of the mixed solution volume.

[0042] 3) Adjust pH=2 with hydrochloric acid with a concentration of 3 mol / L.

[0043] 4) Then pour it into a polytetrafluoroethylene-lined high-pressure hydrothermal reactor, keeping the volume filling ratio at 70%.

[0044] 5) Put the sealed reaction kettle into a homogeneous hydrothermal re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com