Device and method for concentrating kerogen from easily-slimed oil shale

A technology of oil shale and kerogen, applied in the field of oil shale industry, can solve the problems of reducing the purity and conversion utilization rate of oil shale reaction products, affecting economic and social benefits, and harmfulness, so as to improve performance and economic value , Extensive practicability, and the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

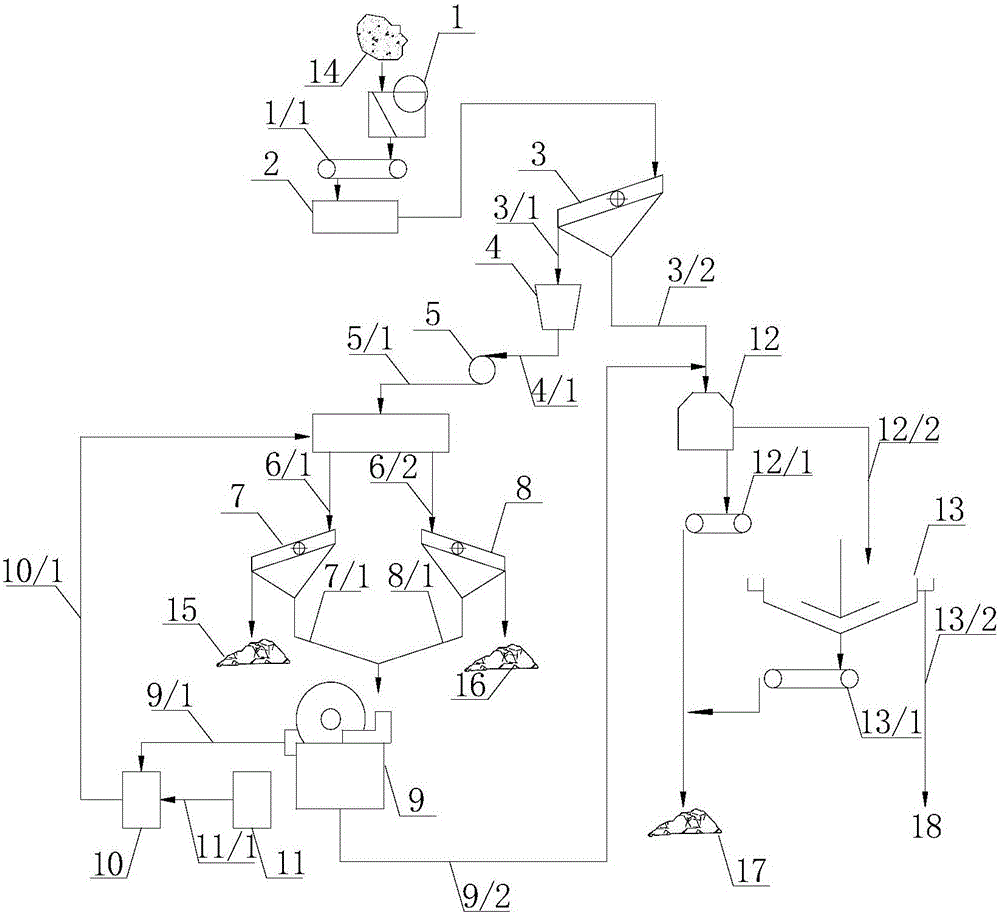

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0011] Such as figure 1 As shown, the easy-to-mud oil shale enrichment kerogen device of the present invention is mainly composed of a crusher 1, mud equipment 2, vibrating screen 3, mixing tank 4, feed pump 5, heavy medium separation equipment 6, light Product removal and dehydration screen 7, heavy product removal and dehydration screen 8, magnetic separator 9, qualified medium barrel 10, additional medium barrel 11, centrifuge 12, thickener 13; the output port of crusher 1 passes through the belt conveyor and mud The input port of the mudification equipment 2 is connected, the output port of the mudification equipment has a vibrating screen 3, the outlet under the screen is connected to the inlet of the centrifuge 12 through a pipeline, and the outlet on the screen is connected to the mixing bucket 4 through a chute. The mixing tank 4 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com