Method for preparing nano sliver wire dispersion liquid controllable in wire diameter and high in length-diameter ratio in batches

A high aspect ratio, nano-silver wire technology, applied in the field of nano-materials, can solve the problems of complex preparation process, low yield, and small nano-wire length and diameter, and achieve the effects of simple preparation process, high conversion efficiency, and increased reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation process of this embodiment is as follows:

[0042] (1) Dissolve silver nitrate in glycerol to prepare a silver nitrate glycerol solution with a molar concentration of 0.1mol / L for subsequent use;

[0043] (2) Dissolve polyvinylpyrrolidone-K30 (PVP-K30) in glycerol to prepare a glycerol solution with a molar concentration of 0.1mol / L polyvinylpyrrolidone-K30 (PVP-K30) for later use;

[0044] (3) Lithium chloride is dissolved in glycerol to prepare a lithium chloride glycerol solution with a concentration of 50mmol / L for subsequent use;

[0045] (4) Stir and mix 100mL silver nitrate glycerin solution and 200mL polyvinylpyrrolidone-K30 (PVP-K30) glycerol solution to prepare a mixed solution for later use;

[0046] (5) Add 200 μL of lithium chloride glycerin solution into the mixed solution, stir well, then put it in an oven at 120°C, and react for 5 hours to obtain a high aspect ratio silver nanowire dispersion.

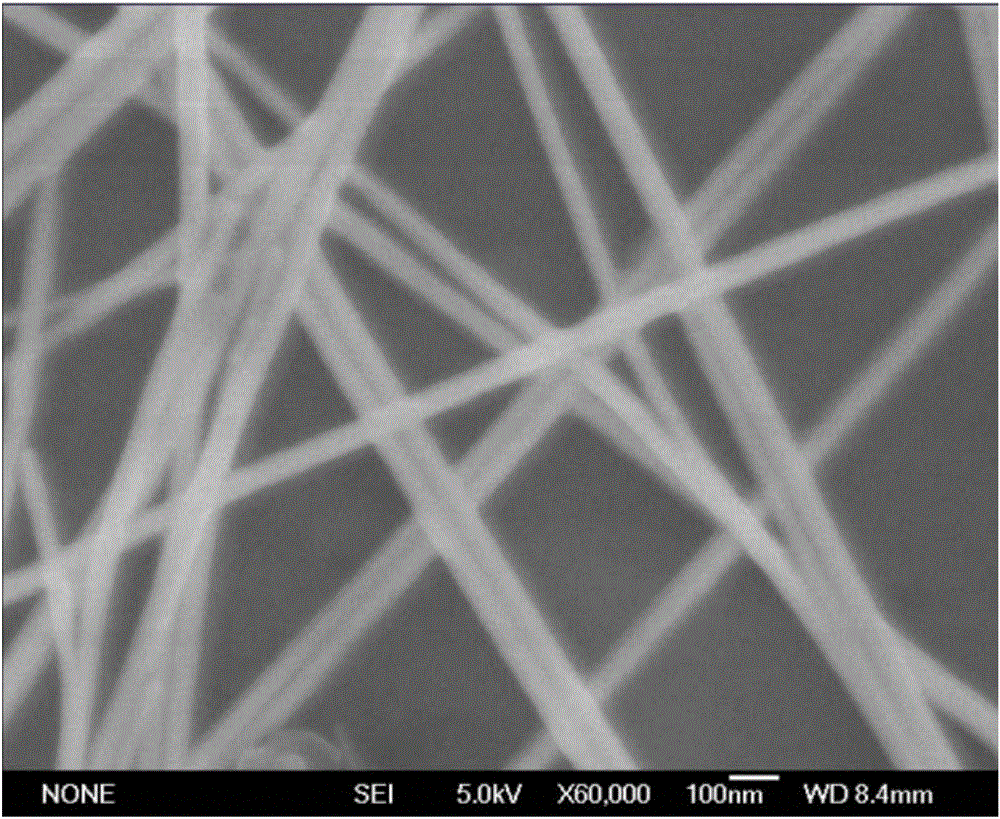

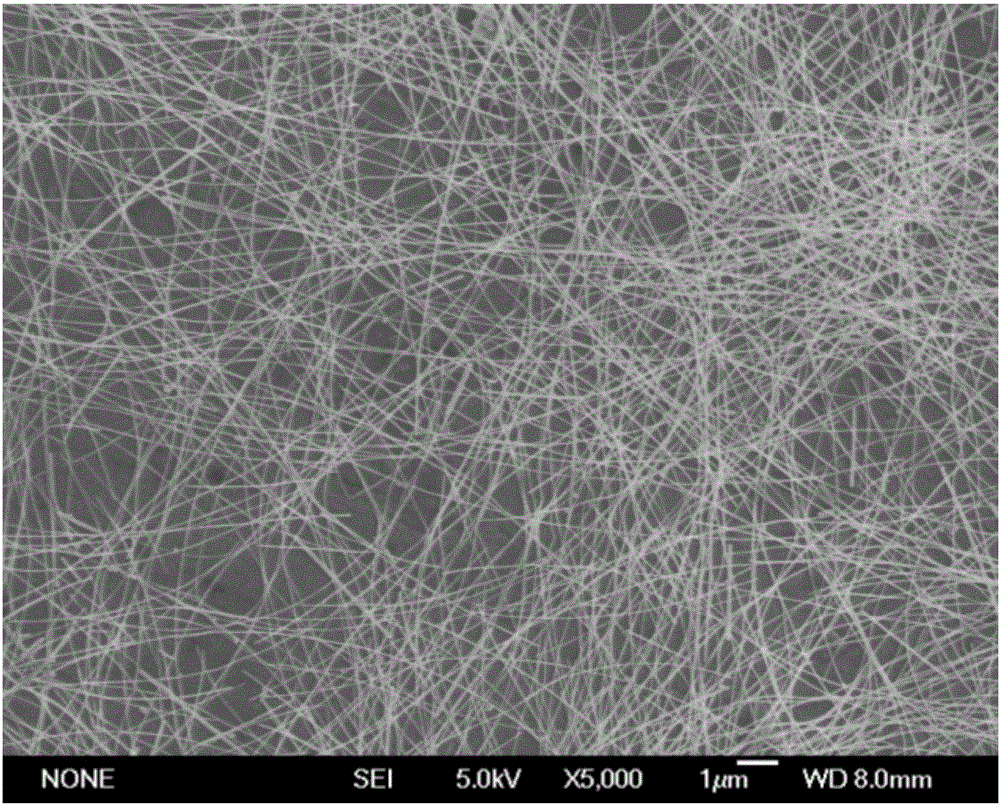

[0047] Then, the prepared high aspect rat...

Embodiment 2

[0050] The preparation process of this embodiment is as follows:

[0051] (1) Dissolve silver nitrate in glycerol to prepare a silver nitrate glycerol solution with a molar concentration of 0.1mol / L for subsequent use;

[0052] (2) Dissolve polyvinylpyrrolidone-K60 (PVP-K60) in glycerol to prepare a glycerol solution with a molar concentration of 0.1mol / L polyvinylpyrrolidone-K60 (PVP-K60) for use;

[0053] (3) Sodium chloride is dissolved in glycerol to prepare a sodium chloride glycerol solution with a concentration of 50mmol / L for subsequent use;

[0054] (4) Stir and mix 100mL silver nitrate glycerin solution and 200mL polyvinylpyrrolidone-K60 (PVP-K60) glycerol solution to prepare a mixed solution for later use;

[0055] (5) Add 1000 μL of sodium chloride glycerin solution into the mixture, stir well, then put it in an oven at 130°C, and react for 10 hours to obtain a dispersion of silver nanowires with high aspect ratio.

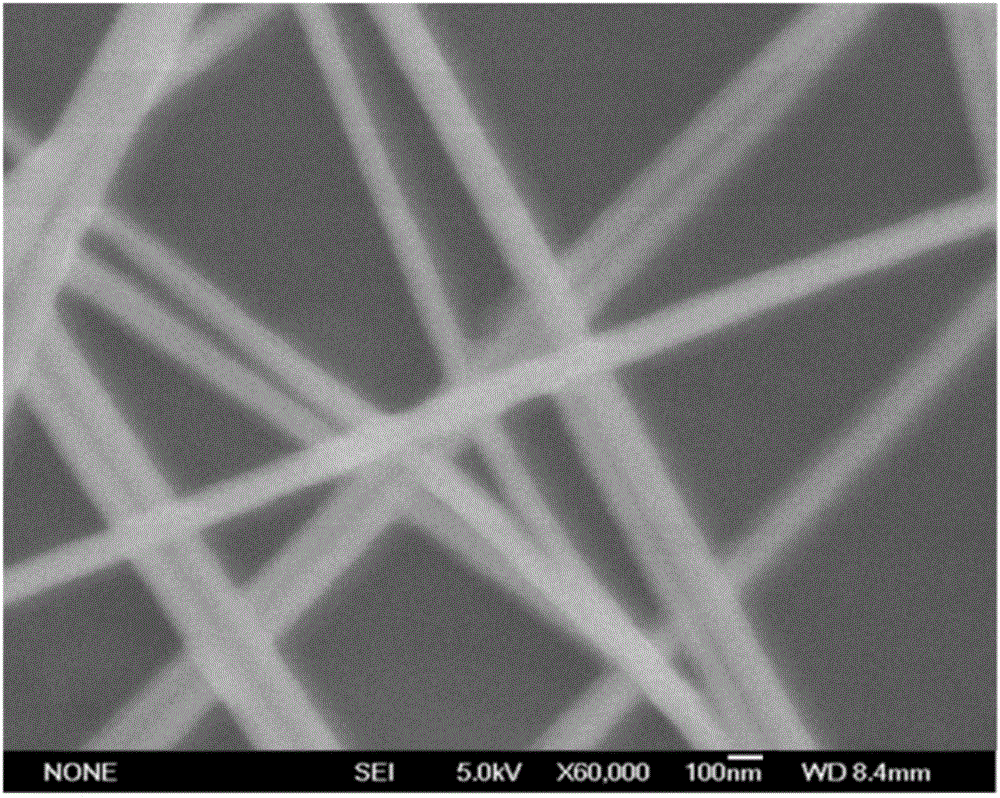

[0056] Then, the prepared high aspect ratio na...

Embodiment 3

[0059] The preparation process of this embodiment is as follows:

[0060] (1) Dissolve silver nitrate in glycerol to prepare a silver nitrate glycerol solution with a molar concentration of 0.1mol / L for subsequent use;

[0061] (2) Dissolve polyvinylpyrrolidone-K30 (PVP-K30) in glycerol to prepare a glycerol solution with a molar concentration of 0.1mol / L polyvinylpyrrolidone-K30 (PVP-K30) for later use;

[0062] (3) Dissolve ferric chloride in ethylene glycol, and prepare a ferric chloride ethylene glycol solution with a concentration of 50mmol / L for subsequent use;

[0063] (3`), sodium chloride is dissolved in ethylene glycol, is mixed with the sodium chloride ethylene glycol solution that concentration is 100mmol / L, for subsequent use;

[0064] (4) Stir and mix 100mL silver nitrate glycerin solution and 200mL polyvinylpyrrolidone-K30 (PVP-K30) glycerol solution to prepare a mixed solution for later use;

[0065] (5) Add 150 μL ferric chloride ethylene glycol solution and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com