La<3+>-doped TiO2 electrochromic thin film and preparation method thereof

An electrochromic and thin-film technology, applied in the direction of coating, etc., can solve the problems of electrochromic performance decline, etc., and achieve the effects of small investment in production equipment, improvement of natural light level, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

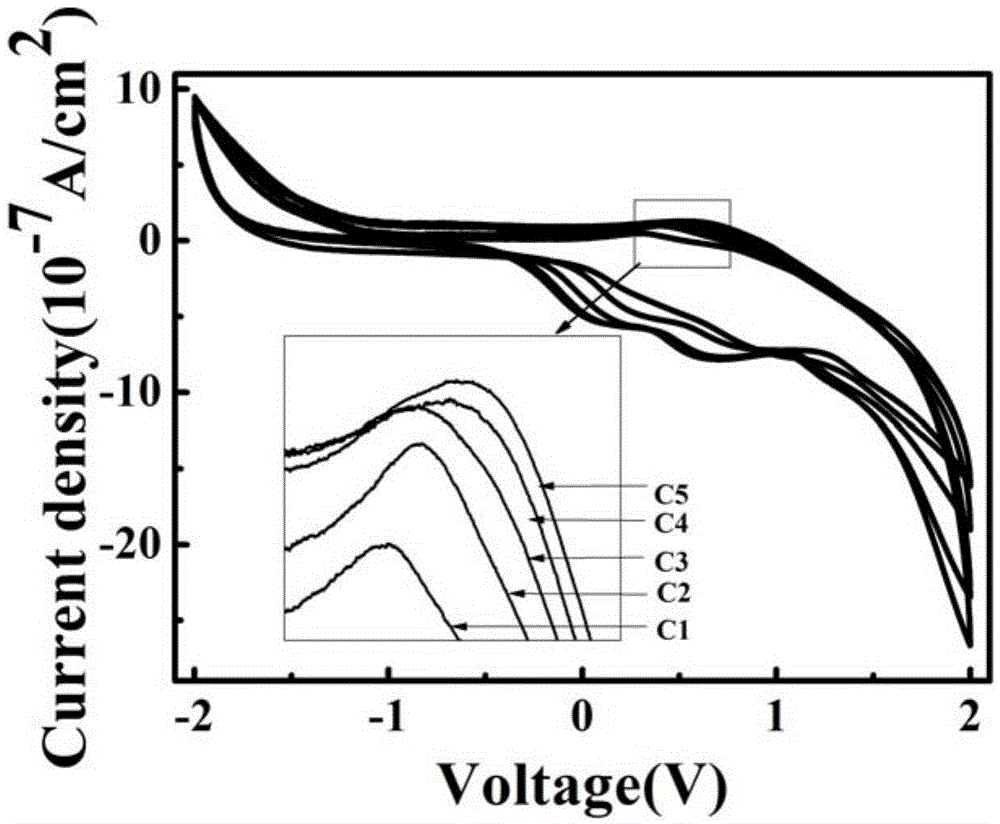

[0028] This embodiment prepares La according to the following steps 3+ doped TiO 2 Electrochromic film:

[0029] Using the sol-gel method, according to the ratio, 40 parts of absolute ethanol, 10 parts of tetrabutyl titanate, and 8 parts of acetic acid were vigorously stirred in a beaker for 1 hour to obtain a uniform and transparent light yellow precursor solution A;

[0030] Then 20 parts of absolute ethanol, 2 parts of deionized water, 3 parts of nitric acid and La 2 o 3 Stir vigorously in a beaker for 30 minutes to obtain a uniform and transparent precursor solution B;

[0031] Finally, mix the precursor solution A and the precursor solution B, continue to stir for 1h, and leave it to age for 12h to obtain La 3+ doped TiO 2 Precursor Sol.

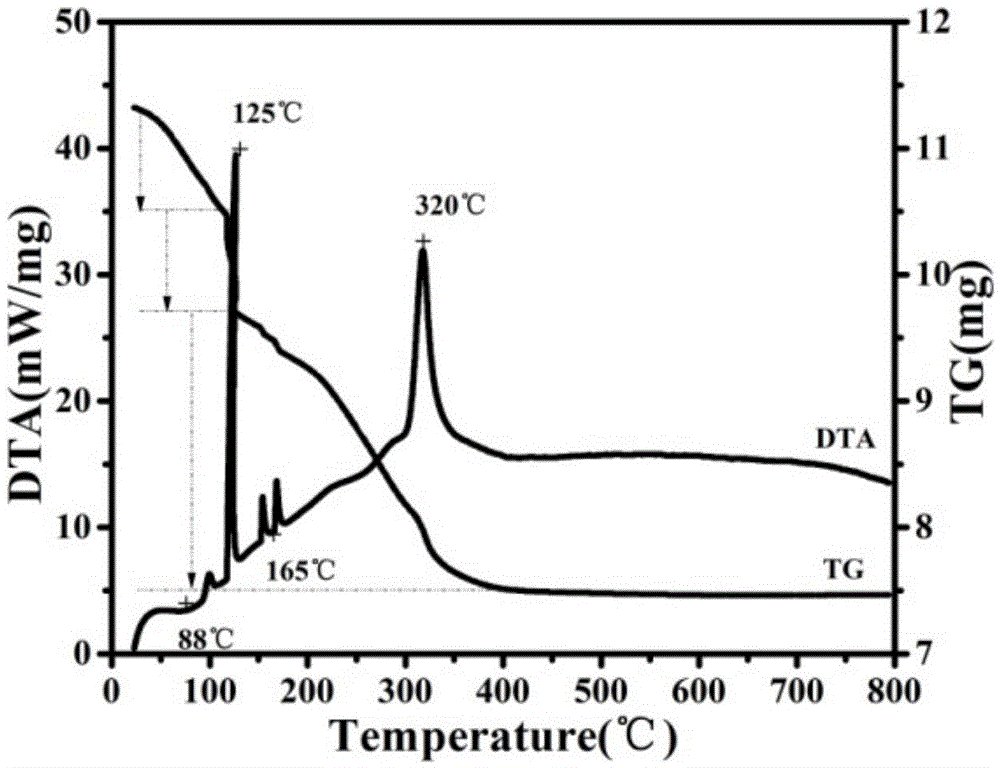

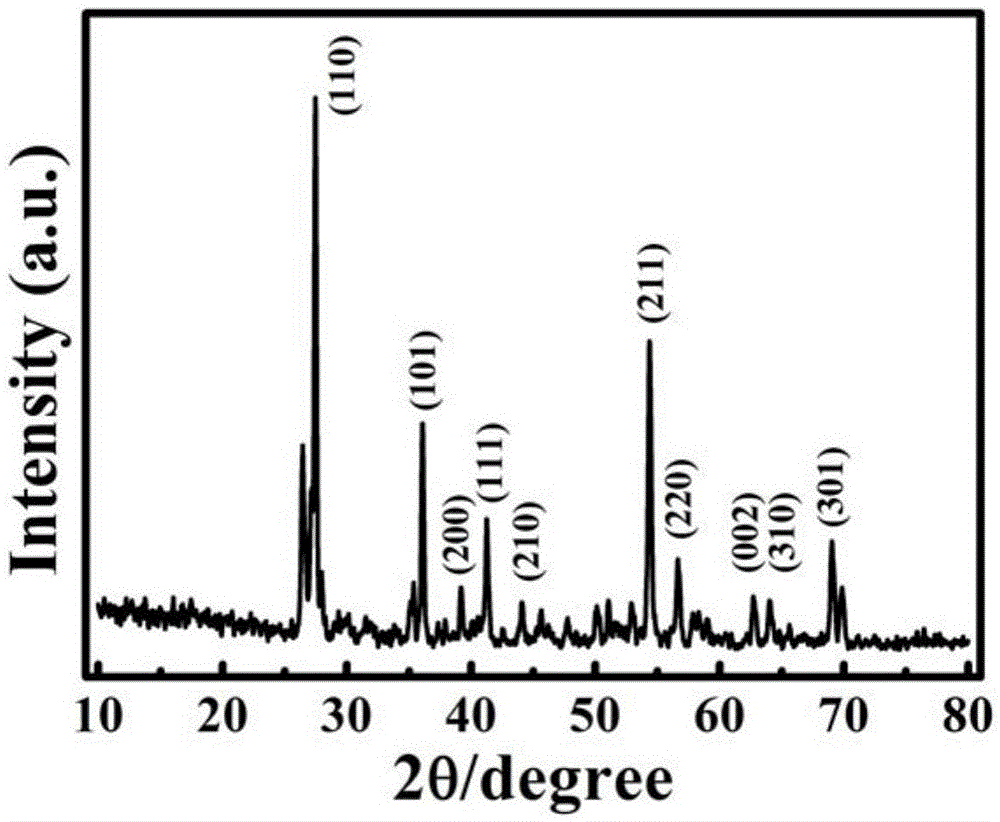

[0032] Using the dipping-pulling method, the ITO conductive glass was immersed in La 3+ doped TiO 2 In the precursor sol, the pull coating was performed at a rate of 3mm / s. Finally, the dried coated glass is fired according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com